Indlela yokuphucula ukumelana nokukrwela kwe-polypropylene

Indlela yokuphucula ukumelana nokukrwela kwe-polypropylene,

Isongezo esichasene nokukrweleka, i-masterbatch ye-silicone echasene nokukrwela, phucula ukumelana nokukrwela,

Inkcazo

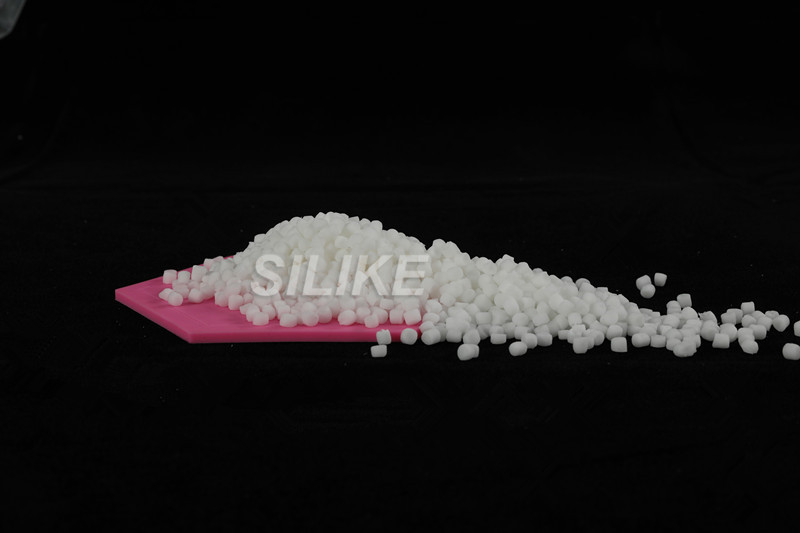

I-Silicone masterbatch LYSI-306C yinguqulelo ephuculweyo ye-LYSI-306, inokuhambelana okuphuculweyo ne-Polypropylene (CO-PP) matrix — Oku kubangela ukwahlulwahlulwa okuncinci komphezulu wokugqibela, oku kuthetha ukuba ihlala kumphezulu weplastiki yokugqibela ngaphandle kokuhamba okanye ukuphuma, ukunciphisa ukufiphala, i-VOCS okanye ivumba. I-LYSI-306C inceda ukuphucula iipropati ezihlala ixesha elide zokuchasana nokukrweleka kwengaphakathi kwemoto, ngokubonelela ngophuculo kwiinkalo ezininzi ezifana noMgangatho, Ukwaluphala, ukuva kwesandla, ukuqokelelana kothuli okunciphileyo… njl. Ifanelekile kwiindidi ezahlukeneyo zomphezulu wangaphakathi wemoto, ezinje: iiphaneli zomnyango, iiDashboards, iiCenter Consoles, iiphaneli zezixhobo.

Iiparameters ezisisiseko

| Ibanga | I-LYSI-306C |

| Inkangeleko | Ipellet emhlophe |

| Umxholo we-silicone % | 50 |

| Isiseko seresin | PP |

| Isalathisi sokunyibilika (230℃, 2.16KG) g/10min | 2 (ixabiso eliqhelekileyo) |

| Idosi% (w/w) | 1.5~5 |

Iinzuzo

I-Silicone masterbatch LYSI-306C isebenza njengearhente yokulwa nokukrweleka komphezulu kunye noncedo lokucubungula. Oku kubonelela ngeemveliso ezilawulwayo nezihambelanayo kunye nemo yendalo eyenzelwe wena.

(1) Iphucula iipropati zokulwa nokukrweleka kweenkqubo ze-TPE,TPV PP,PP/PPO ezizaliswe yiTalc.

(2) Isebenza njengesithambisi sokutyibilika esisisigxina

(3) Akukho kufuduka

(4) Ukukhutshwa kwe-VOC ephantsi

Kusetyenziswa kwanjani

Kucetyiswa ukuba kubekho amanqanaba okongeza phakathi kwe-0.5 ~ 5.0%. Ingasetyenziswa kwinkqubo yokuxuba i-melt yakudala efana nee-Single / Twin screw extruders, i-injection molding. Kucetyiswa umxube ongokoqobo kunye nee-virgin polymer pellets.

Iphakheji

25Kg/ibhegi, ibhegi yephepha lobugcisa

Indawo yokugcina izinto

Thutha njengekhemikhali engenabungozi. Gcina kwindawo epholileyo, enomoya owaneleyo.

Beka ubomi kwishelufa

Iimpawu zokuqala zihlala zinjalo kangangeenyanga ezingama-24 ukusukela kumhla wokuveliswa, ukuba zigcinwe kwindawo yokugcina ecetyiswayo. Ukuphucula ukumelana nokukrwela kwe-polypropylene (PP) yinto ebalulekileyo ekufuneka iqwalaselwe kumashishini amaninzi, ukusuka kwiimoto ukuya kumveliso wezixhobo zonyango. I-PP yi-polymer ye-thermoplastic elula, enamandla, kwaye imelana neekhemikhali ezininzi. Nangona kunjalo, inokuba sengozini yokukrwela nokukrwela. Ngethamsanqa, kukho iindlela ezahlukeneyo zokuphucula ukumelana nokukrwela kwe-PP.

1. Yongeza iiFillers: Ukongeza iiFillers ezifana neefayibha zeglasi okanye i-talc kunokunceda ukuphucula ukumelana nokukrwela kwe-PP. IiFillers zisebenza njenge-buffer phakathi komphezulu wento kunye nayo nayiphi na imikhosi erhabaxa enokuthi idibane nayo. Oku kunceda ukunciphisa umonakalo obangelwa yimikrwelo kunye nokukrwela.

2. Yongeza into ethintela ukukrweleka, efana ne-masterbatch ye-silicone ethintela ukukrweleka,

Ukusetyenziswa kwe-masterbatch ye-silicone elwa nokukrwela kwizinto ze-PP, Okokuqala, kunokunciphisa inani lemikrwelo eyenzeka kumphezulu wezinto. Oku kungenxa yokuba amasuntswana e-silicone kwi-masterbatch asebenza njenge-lubricant, enceda ekunciphiseni ukungqubana phakathi kwezinto kwaye ngaloo ndlela kunciphise ukukrwela. Ukongeza, kunokunceda ukwandisa amandla kunye nokuqina kwezinto ze-PP, kunye nokuphucula ukumelana kwazo nobushushu kunye nozinzo lwe-UV.

3. Sebenzisa iiBlends: Ukudibanisa iPP nezinye izinto ezifana ne-polyethylene (PE) okanye i-polycarbonate (PC) kunokunceda ukuphucula ukumelana kwayo nokukrwela. Ukongezwa kwezi zinto kunceda ekudaleni izinto ezihlala ixesha elide ezikwaziyo ukumelana namandla arhabaxa ngaphandle kokonakala okanye ukukrwela.

4. Faka iiCoatings: Ukusebenzisa iiCoatings ezifana neepeyinti okanye iiVarnishes kunokunceda ukuphucula ukumelana nokukrwela kwePP. Ezi coatings zibonelela ngomaleko owongezelelweyo wokhuseleko kwimikrwelo nokukrwela, nto leyo enceda ukugcina impahla ibukeka intsha ixesha elide.

Izongezo zeSilicon zasimahla kunye neesampuli zeSi-TPV ezingaphezulu kwamaBanga ali-100

Uhlobo lwesampulu

$0

- Ngaphezulu kweminyaka engama-50

amabakala eSilicone Masterbatch

- 10+

amabakala eSilicone Powder

- 10+

amabakala I-Masterbatch yokulwa nokukrwela

- 10+

amabakala I-Masterbatch yokulwa nokukrala

- 10+

amabakala e-Si-TPV

- 8+

amabakala e-Silicone Wax

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

I-Whatsapp

-

Phezulu

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur