Izinto ezifunekayo mihla le njengokutya nezinto zasekhaya zibalulekile kubomi babantu bemihla ngemihla. Njengoko isantya sobomi siqhubeka sikhawuleza, ukutya okupakishweyo okuhlukeneyo kunye nezinto ezifunekayo imihla ngemihla kuye kwazalisa iivenkile ezinkulu kunye neevenkile ezinkulu, okwenza kube lula kubantu ukuthenga, ukugcina, nokusebenzisa ezi zinto. Izinto zokupakisha zidlala indima ebalulekileyo kule ndlela ilula. Ngophuhliso oluqhubekayo lweshishini lokupakisha, imigca yokuvelisa ukupakisha ngokuzenzekelayo isetyenziswa ngakumbi ekuveliseni ukutya kunye nezinto eziyimfuneko zemihla ngemihla. Njengoko isantya kunye nokuziqhelanisa kweematshini zokupakisha kuqhubeka kusanda, imiba yomgangatho nayo iye yabonakala. Iingxaki ezinje ngokwaphuka kwefilimu, ukutyibilika, ukuphazamiseka kwemigca yokuvelisa, kunye nokuvuza kweepakeji kuya kuxhaphaka, nto leyo ebangela ilahleko enkulu kubavelisi abaninzi bezinto zokupakisha eziguquguqukayo kunye neenkampani zokushicilela. Isizathu esiphambili sikukungakwazi ukulawula iipropati zokungqubana kunye nokuvala ubushushu beefilimu zokupakisha ngokuzenzekelayo.

Okwangoku, iifilimu zokupakisha ezizenzekelayo ezikwimarike zineziphene ezilandelayo eziphambili:

- Umaleko wangaphandle wefilimu yokupakisha une-coefficient ephantsi yokungqubana (i-COF), ngelixa umaleko wangaphakathi une-COF ephezulu, nto leyo ebangela ukutyibilika ngexesha lokuqhuba kwefilimu kumgca wokupakisha.

- Ifilimu yokupakisha isebenza kakuhle kumaqondo obushushu aphantsi kodwa ihlangabezana neengxaki kumaqondo obushushu aphezulu ngexesha lenkqubo yokupakisha ngokuzenzekelayo.

- I-COF ephantsi yomaleko wangaphakathi ithintela indawo efanelekileyo yomxholo ngaphakathi kwefilimu yokupakisha, nto leyo ekhokelela ekungasebenzini kokuvala xa umcu wokuvala ubushushu ucinezela umxholo.

- Ifilimu yokupakisha isebenza kakuhle ngesantya esiphantsi kodwa ihlangabezana neengxaki zokuvaleka kobushushu kunye nokuvuza njengoko isantya somgca wokupakisha sisanda.

Ngaba uyayiqonda into yokubaI-COFyefilimu yokupakisha ezenzekelayo? Eqhelekileyoiiarhente ezithintela ukuvimba kunye nokutyibilikakunye nemingeni

I-COF ilinganisa iimpawu zokutyibilika kwezinto zokupakisha. Ubuthambile bomphezulu wefilimu kunye ne-COF efanelekileyo zibalulekile kwinkqubo yokupakisha ifilimu, kunye neemveliso ezahlukeneyo zezinto zokupakisha ezineemfuno ezahlukeneyo ze-COF. Kwiinkqubo zokupakisha zokwenyani, ukungqubana kunokusebenza njengokuqhuba kunye namandla okuchasana, nto leyo ebangela ulawulo olusebenzayo lwe-COF ngaphakathi koluhlu olufanelekileyo. Ngokubanzi, iifilimu zokupakisha ezizenzekelayo zifuna i-COF ephantsi kakhulu kumaleko wangaphakathi kunye ne-COF ephakathi kumaleko wangaphandle. Ukuba i-COF yomaleko wangaphakathi iphantsi kakhulu, inokubangela ukungazinzi kunye nokungahambi kakuhle ngexesha lokwenziwa kwengxowa. Ngokwahlukileyo koko, ukuba i-COF yomaleko wangaphandle iphezulu kakhulu, inokubangela ukumelana okugqithisileyo ngexesha lokupakisha, okukhokelela ekuguqulweni kwezinto, ngelixa i-COF ephantsi kakhulu inokubangela ukutyibilika, okubangela ukulandelela kunye nokusika ukungachaneki.

I-COF yeefilimu ezidityanisiweyo ichaphazeleka ngumxholo wee-anti-blocking kunye nee-slip agents kumaleko angaphakathi, kunye nokuqina kunye nokuthamba kwefilimu. Okwangoku, ii-slip agents ezisetyenziswa kwiileko zangaphakathi zihlala ziyi-fatty acid amide compounds (ezifana nee-primary amides, ii-secondary amides, kunye nee-bisamides). Ezi zinto azinyibiliki ngokupheleleyo kwiipolymers kwaye zihlala zifudukela kumphezulu wefilimu, nto leyo enciphisa ukungqubana komphezulu. Nangona kunjalo, ukufuduka kwee-amide slip agents kwiifilimu zepolymer kuchatshazelwa zizinto ezahlukeneyo, kubandakanya uxinano lwe-slip agent, ubukhulu befilimu, uhlobo lwe-resin, uxinzelelo lwe-winding, indawo yokugcina, ukucutshungulwa kwe-downstream, iimeko zokusetyenziswa, kunye nezinye izongezo, okwenza kube nzima ukuqinisekisa i-COF ezinzileyo. Ngaphezu koko, njengoko iipolymers ezininzi zicutshungulwa kumaqondo obushushu aphezulu, uzinzo lwe-oxidative lobushushu lwee-slip agents luba lubaluleke ngakumbi. Ukuwohloka kwe-oxidative kunokukhokelela ekulahlekelweni kokusebenza kwe-slip agent, ukutshintsha kombala, kunye nevumba.

Ezona arhente zokutyibilika zixhaphakileyo ezisetyenziswa kwi-polyolefins zii-amides ze-fatty acid ezineetyathanga elide, ukusuka kwi-oleamide ukuya kwi-erucamide. Ukusebenza kweearhente zokutyibilika kungenxa yokukwazi kwazo ukuhla kumphezulu wefilimu emva kokukhupha. Iiarhente zokutyibilika ezahlukeneyo zibonisa amazinga ahlukeneyo okuna kwemvula kumphezulu kunye nokunciphisa i-COF. Njengoko iiarhente zokutyibilika ze-amide ziyiarhente zokutyibilika eziphantsi kobunzima be-molecular, ukufuduka kwazo ngaphakathi kwefilimu kuphenjelelwa zizinto ezahlukeneyo, okubangela i-COF engaguqukiyo. Kwiinkqubo zokutyibilika ezingenasombululo, iiarhente zokutyibilika ze-amide ezininzi kwifilimu zinokubangela imiba yokusebenza kokutywinwa kobushushu, okubizwa ngokuba "kukuvinjelwa." Le ndlela ibandakanya ukufuduka kwee-monomers ze-isocyanate zasimahla kwi-adhesive kumphezulu wefilimu, zisabela kwi-amide ukuze zenze i-urea. Ngenxa yenqanaba eliphezulu lokunyibilika kwe-urea, oku kubangela ukusebenza okunciphileyo kokutywinwa kobushushu kwefilimu elaminethiweyo.

Ni-oven i-super slip engafudukiyo&Ukuchasana nokuvalekaiarhente

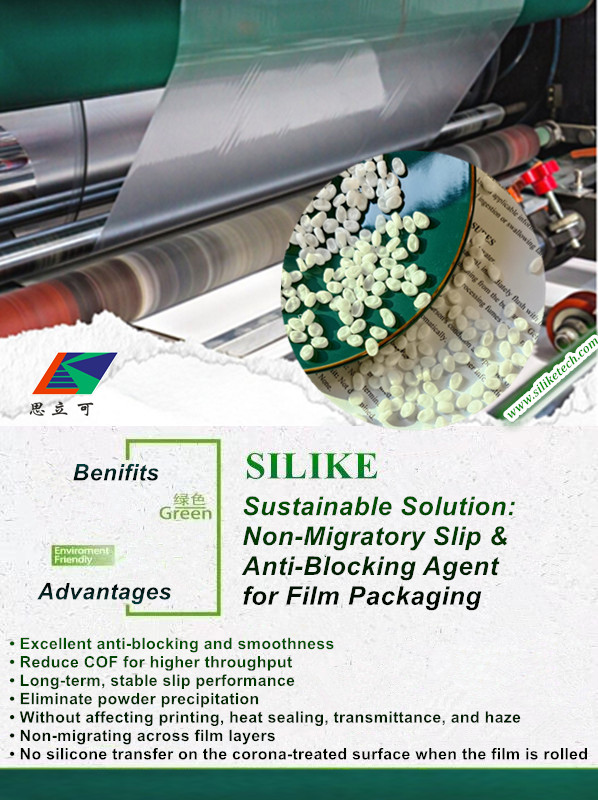

Ukujongana nale micimbi, i-SILIKE iqalise I-Super-slip engangenisi amanzi kunye ne-Anti-blocking Masterbatch Additive– yinxalenye yothotho lwe-SILIMER. Ezi mveliso ze-polysiloxane ezilungisiweyo ziqulathe amaqela asebenzayo e-organic. Iimolekyuli zazo ziquka zombini iinxalenye ze-polysiloxane chain kunye neentambo ze-carbon ezinde ezinamaqela asebenzayo. Iintambo ze-carbon ezinde zamaqela asebenzayo anokudibana ngokwasemzimbeni okanye ngokweekhemikhali ne-base resin, zibambe iimolekyuli kwaye zenze kube lula ukuhamba ngaphandle kwemvula. Iinxalenye zentambo ze-polysiloxane kumphezulu zibonelela ngesiphumo sokuthambisa.

Ngokukodwa,I-SILIMER 5065HByenzelwe iifilimu ze-CPP, kwayeI-SILIMER 5064MB1ifanelekile kwiifilimu ezifakwe i-PE kunye neengxowa zokupakisha ezidityanisiweyo. Iingenelo zezi mveliso ziquka:

- I-SILIMER 5065HBkwayeI-SILIMER 5064MB1zibonelela ngokugqwesileyo ngokulwa nokuvaleka kunye nobuthambileyo, nto leyo ebangela ukuba i-COF ingabi nkulu.

- I-SILIMER 5065HBkwayeI-SILIMER 5064MB1inika ukusebenza okuzinzileyo nokusisigxina kokutyibilika ngokuhamba kwexesha naphantsi kweemeko zobushushu obuphezulu, ngaphandle kokuchaphazela ukuprinta, ukuvala ubushushu, ukuhanjiswa, okanye inkungu.

- I-SILIMER 5065HBkwayeI-SILIMER 5064MB1susa ukuna kwempuphu emhlophe, ukuqinisekisa ukuthembeka kunye nobuhle bokupakisha.

Uthotho lweearhente zokutyibilika zeSILIKE's SILIMER ezingaqhakaziyoibonelela ngesisombululo esigqibeleleyo sokulawula i-COF yeefilimu zokupakisha ezizenzekelayo, ukusuka kwiCast Polypropylene Films, iifilimu ze-PE-blown ukuya kwiifilimu ezahlukeneyo ezisebenzayo ezidityanisiweyo. Ngokujongana nemiba yokufuduka kwee-slip agents zendabuko kunye nokuphucula kakhulu ukusebenza kunye nokubonakala kweefilimu zokupakisha, i-SILIKE inikezela ukhetho oluthembekileyo kubavelisi bezixhobo zokupakisha eziguquguqukayo kunye neenkampani zokuprinta.

Qhagamshelana nathi Ucingo: +86-28-83625089 okanye nge-imeyile:amy.wang@silike.cn.

iwebhusayithi:www.siliketech.comukuze ufunde okungakumbi.

Ixesha leposi: Julayi-09-2024