Ifilimu yeplastiki yenziwe nge-PE, PP, PVC, PS, PET, PA, kunye nezinye iiresini, ezisetyenziselwa ukupakisha okuguquguqukayo okanye umaleko wokulaminetha, zisetyenziswa kakhulu ekutyeni, kumayeza, kwiikhemikhali, nakwamanye amasimi, apho ukupakisha ukutya kube yinxalenye enkulu. Phakathi kwazo, ifilimu ye-PE yeyona isetyenziswa kakhulu, inani elikhulu lefilimu yokupakisha yeplastiki, ebalelwa ngaphezulu kwe-40% yokusetyenziswa kwefilimu yokupakisha yeplastiki.

Ngexesha lokulungiselela iifilimu zeplastiki, ukuphucula ukusebenza kwazo kunye nobomi benkonzo, kudla ngokuba yimfuneko ukongeza ii-slip agents. Ii-slip agents zinokunciphisa i-friction coefficient yomphezulu weefilimu zeplastiki kwaye ziphucule ukuguda komphezulu wazo, ngaloo ndlela ziphucule ukusebenza kwazo kwaye zandise ubomi benkonzo yazo.

Okwangoku, ii-agents zokutyibilika eziqhelekileyo ziquka i-amide, i-silicone ye-polymer ephezulu kakhulu, i-copolymer polysiloxane, njl. Iintlobo ezahlukeneyo zee-agents zokutyibilika kwefilimu zineempawu ezahlukeneyo kunye neenzuzo kunye neengxaki, oku kulandelayo kwazisa ngokufutshane ii-agents ezininzi zokutyibilika eziqhelekileyo kunye nendlela yokukhetha izongezo zokutyibilika kwiFilimu yePlastiki:

Ii-Amide slip agents (kuquka i-oleic acid amides, i-erucic acid amides, njl.njl.):

Indima ephambili yezongezo ze-amide kwimveliso yefilimu ye-polyolefin kukunika iipropati zokutyibilika. Emva kokuba i-amide slip agent ishiye isikhunta, i-slip agent ifudukela ngoko nangoko kumphezulu wefilimu ye-polymer, kwaye yakufika kumphezulu, i-slip agent yenza umaleko wokuthambisa, onciphisa i-coefficient of friction kwaye ifezekise isiphumo esityibilikayo.

- Iingenelo zee-amide slip agents kwiPlastiki Film:

Isixa esiphantsi sokongeza xa kulungiswa ifilimu (0.1-0.3%), songezwa ngendlela yomxube okanye i-masterbatch kwisityalo sokucubungula ukuqinisekisa isiphumo sokugudisa esifanayo; isiphumo esihle sokugudisa, sinokufikelela kwi-coefficient ephantsi yokungqubana, isixa esiphantsi kakhulu sokongeza sinokuhlangabezana neemfuno.

- Iingxaki ze-amide slip agents kwiFilimu yePlastiki:

Impembelelo ekuprinteni:ikhawuleza, nto leyo ekhokelela kwimpembelelo kwi-corona nakwiprinta.

Iimfuneko eziphezulu zobushushu bemozuluUmzekelo, isixa esongezwayo ehlotyeni nasebusika sahlukile. Ngenxa yobushushu obuphezulu obuqhubekayo ehlotyeni, izinto zokuthambisa ezifana ne-erucic acid amide kulula kakhulu ukuzifudusela ngokuqhubekayo ukusuka kumphezulu wefilimu, kwaye isixa esifuduselwe kumphezulu wefilimu siya kuhlanganiswa njengoko ixesha lihamba, nto leyo ekhokelela ekwandeni kombala wefilimu ecacileyo, nto leyo echaphazela inkangeleko kunye nomgangatho wezinto zokupakisha. Ikwanamathela kwimiqulu yesinyithi.

Ubunzima bokugcina:Ii-Amide film slip agents nazo zinokufuduka ukusuka kwi-heat seal layer ziye kwi-corona layer emva kokuba ifilimu ityunyuziwe kwaye ngexesha lokugcinwa kwayo kamva, nto leyo echaphazela kakubi imisebenzi engaphantsi komsinga efana nokuprinta, ukulaminatha, kunye nokutywina ubushushu.

EKulula kakhulu ukuwenza umgubo omhlophe ube mhlophe:Kwiphakheji yokutya, njengoko i-slip agent ifudukela kumphezulu, inokunyibilika kwimveliso yokutya, nto leyo echaphazela incasa kwaye inyuse umngcipheko wokungcola kokutya.

Iiarhente zokutyibiliza zesilicone ezinobunzima obukhulu kakhulu kwifilimu yeplastiki:

I-polysiloxane enobunzima obuphezulu kakhulu inomdla wokufudukela kumaleko womphezulu, kodwa uthotho lwe-molecular lude kakhulu ukuba lungagutyungelwa ngokupheleleyo, kwaye inxalenye egutyungelweyo yenza umaleko wokuthambisa oqulethe i-silicone kumphezulu, ngaloo ndlela ifezekisa isiphumo sokutyibilika komphezulu.

- Iingenelo:

ukumelana okugqwesileyo kobushushu obuphezulu, imvula ecothayo, ifanelekile ngakumbi kwimigca yokupakisha ezenzekelayo ekhawulezayo (njengefilimu yecuba).

- Iingxaki:

kulula ukuyichaphazela into ecacileyo.

Nangona ezi amide Slip Additives zemveli zisetyenziswa kakhulu kwifilimu yeplastiki, eli shishini linemingeni yalo.

Ngenxa yokwakheka kwayo, iimpawu zayo zolwakhiwo, kunye nobunzima bayo obuncinci beemolekyuli, ii-Amide film slip agents zemveli zisengozini enkulu yokuna kwemvula okanye ukufuthwa ngumgubo, nto leyo enciphisa kakhulu ukusebenza kwe-slip agent, i-coefficient of friction ayizinzanga ngokuxhomekeke kubushushu, kwaye isikrufu kufuneka sicocwe rhoqo, kwaye sinokubangela umonakalo kwizixhobo nakwimveliso.

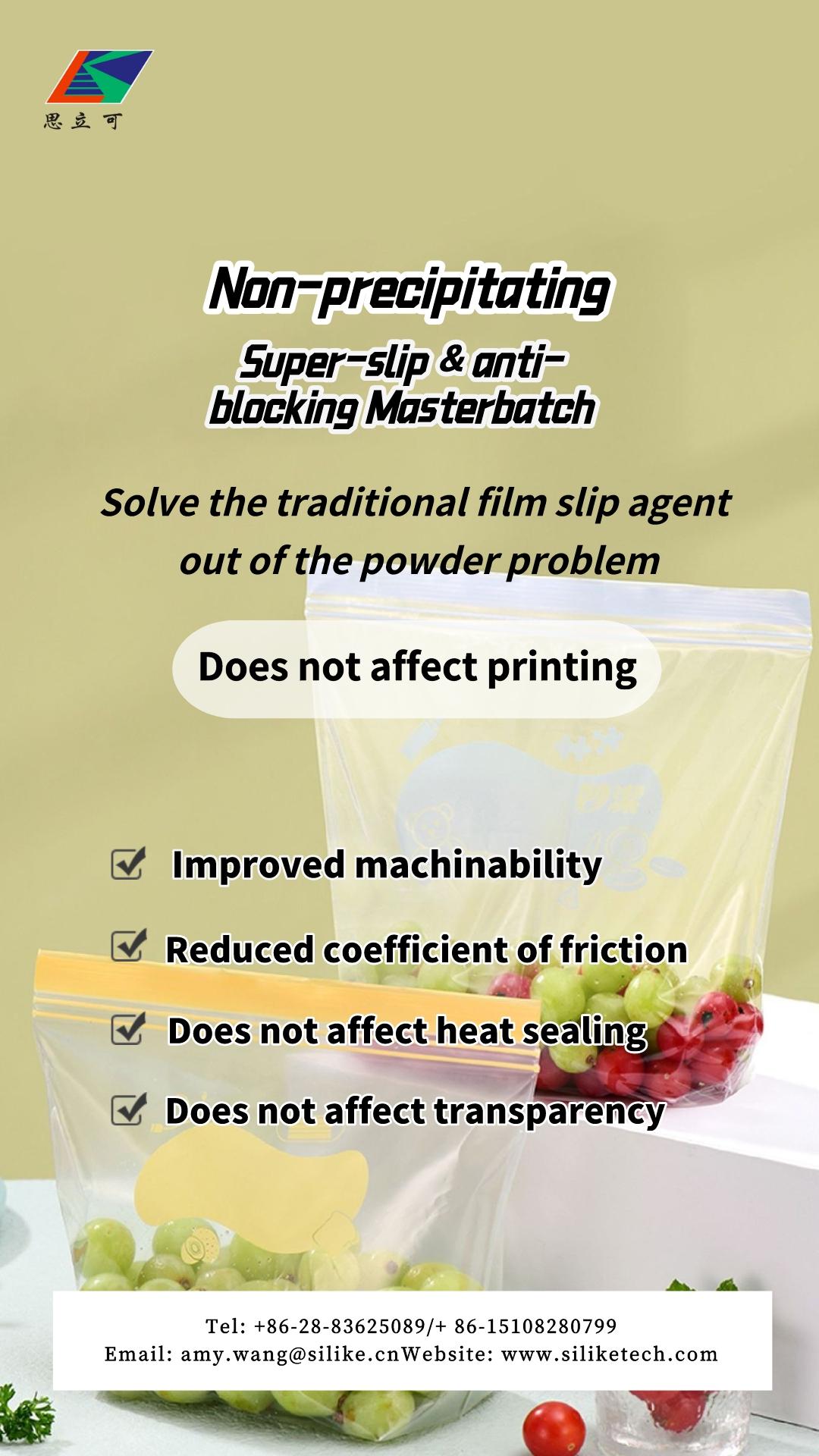

Ukujongana nemingeni kwiShishini leeFilimu zePlastiki:Isisombululo Esitsha sikaSILIKE

Ukujongana nemingeni emininzi ngeeSlip Additives zemveli ezisetyenziswa kwimveliso yefilimu yeplastiki, ingakumbi ngee-slip agents zemveli ezisekelwe kwi-amide. Iqela le-R&D elizinikeleyo le-SILIKE liphumelele ekusombululeni le micimbi ngophuhliso lweIzongezo zeMasterbatch ezingatyibilikiyo nezithintela ukuvimba ezingaqhelekanga– inxalenye yeUthotho lwe-SILIMER, esombulula ngempumelelo iintsilelo zearhente yokutyibilika yendabuko, engafudukiyo kwiileya zefilimu, iqinisekisa ukusebenza kokutyibilika okuzinzileyo nokuhlala ixesha elide, okuzisa ubuchule obukhulu kwishishini lePlastiki Film Flexible Packaging Industry. Olu phuculo lubonelela ngeenzuzo ezifana nefuthe elincinci ekuprinteni, ekuvaleni ubushushu, ekudluliseleni, okanye kumnkungu, kunye neCoF enciphileyo, ukuthintela ukuvaleka okuhle, kunye nokuthamba komphezulu okuphuculweyo, okususa ukuna komgubo omhlophe.

Uthotho lweSILIMER olungenamanzi oluyiSuper-slip kunye noluhlu lweMasterbatch Additives oluthintela ukuvimbaineendlela ezahlukeneyo zokusetyenziswa kwaye ingasetyenziswa ekuveliseni iifilimu zeBOPP/CPP/PE/TPU/EVA, njl. Zifanelekile kwiinkqubo zokubumba, ukubumba ngebhombu, kunye nokuzolula.

NgobaIzithako zeSILIMER ezingezizo ezongezayo zeMasterbatch ezithintela ukutyibilika kakhuluingcono kunee-amide-based slip agents eziqhelekileyo?

Izisombululo Ezimangalisayo Zobuchule Bobuchwephesha Befilimu Yeplastiki

I-Copolymer Polysiloxane:I-SILIKE iqalise i-Masterbatch Additives engeyiyo i-precipitating Super-slip kunye ne-anti-blocking Additives– inxalenye yeUthotho lwe-SILIMER, eziziimveliso ze-polysiloxane eziguquliweyo eziqulathe amaqela asebenzayo e-organic, iimolekyuli zayo ziqulathe zombini iinxalenye ze-polysiloxane chain kunye ne-long carbon chain yamaqela asebenzayo, i-long carbon chain yamaqela asebenzayo inokudityaniswa ngokomzimba okanye ngokweekhemikhali ne-base resin, inokudlala indima yokubambelela, ukufezekisa isiphumo sokufuduka lula ngaphandle kwemvula, iinxalenye ze-silicone chain kumphezulu, ngaloo ndlela zidlala isiphumo esigudileyo.

Iingenelo zeIzithako zeSILIKE SILIMER ezingatshibilikisiyo kakhulu kwaye ezithintela ukuvimba zeMasterbatch:

1. Idatha yovavanyo ibonisa ukuba zincinciI-SILIKE SILIMER 5064MB1kunyeI-SILIKE SILIMER 5065HBinokunciphisa ngempumelelo i-coefficient of friction kwaye ihlale ixesha elide kwaye izinzile kungakhathaliseki ukuba imozulu kunye nobushushu bunjani;

2. Ukongezwa kweI-SILIKE SILIMER 5064MB1kunyeI-SILIKE SILIMER 5065HBngexesha lokulungiselela iifilimu zeplastiki akuchaphazeli ukucaca kwefilimu kwaye akuchaphazeli inkqubo yokuprinta elandelayo;

3.UkongezaI-SILIKE SILIMER 5064MB1kunyeI-SILIKE SILIMER 5065HBngobuninzi obuncinci kusombulula ingxaki yokuba ii-amide slip agents zemveli kulula ukuzilungisa okanye ukuzisusa zibe yimpuphu, kuphucula umgangatho wemveliso, kwaye konga iindleko ezipheleleyo.

Uzinzo kunye nokusebenza kakuhle okuphezulu kweUthotho lweSILIKE SILIMER lweZithako zeMasterbatch ezingatyibilikiyo nezithintela ukuvimbaNdizenze zasetyenziswa kwiindawo ezininzi, ezifana nokuveliswa kweefilimu zeplastiki, iifilimu zokupakisha ezidityanisiweyo, izixhobo zokupakisha ukutya, ukwenziwa kwezixhobo zokupakisha amayeza, njl. I-SILIKE ikwabonelela abathengi ngezisombululo zemveliso ezithembekileyo nezikhuselekileyo, Ngaba ufuna ukutshintsha iiarhente zokufaka i-amide slip ezandleni zakho? Ngaba ufuna ukutshintsha iarhente yakho yokufaka i-amide slip kwiFilimu yeplastiki, okanye ufuna ukusebenzisa iarhente yokukhusela okusingqongileyo ezinzileyo nesebenzayo kwiFilimu yeplastiki, i-SILIKE iyakwamkela ukuba unxibelelane nathi nangaliphi na ixesha, kwaye sijonge phambili ekudaleni amathuba amaninzi kunye nawe!

Ixesha lokuposa: Jan-10-2024