Ii-silicone masterbatch/Ii-composites ze-polyethylene ezixineneyo (LLDPE) ezinemixholo eyahlukeneyo ye-silicone masterbatch 5%, 10%, 15%, 20%, kunye ne-30%) zenziwe ngendlela yokucinezela ngobushushu kwaye ukusebenza kwazo kwe-tribological kwavavanywa.

Iziphumo zibonisa ukuba umxholo we-silicone masterbatch unefuthe elikhulu ekusebenzeni kokungqubana kwe-composite. I-friction coefficient yee-composites inokuncipha ngokwanda komxholo we-silicone masterbatch.

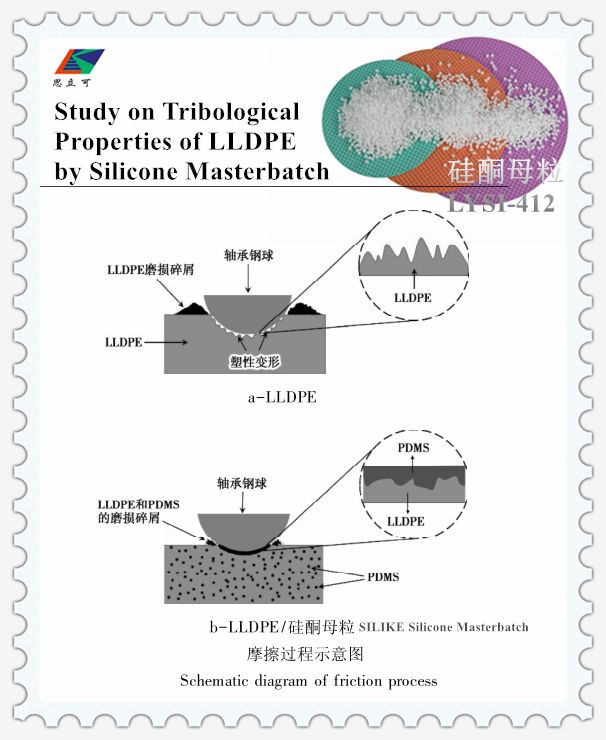

Xa umxholo we-silicone masterbatch uyi-5%, ubungakanani bokuguguleka bunokwehla nge-90.7%, oko kuthetha ukuba i-silicone masterbatch encinci inokuphucula ukumelana nokuguguleka. Njengoko umthwalo osetyenzisiweyo unyuka ukusuka kwi-10 N ukuya kwi-20 N, i-friction coefficient iyahluka ukusuka ku-0.33-0.54 kunye no-0.22-0.41, okubonisa ukuba umthwalo ophezulu unokuba negalelo ekwehleni kwe-friction coefficient ye-composite. Uhlalutyo lwesakhiwo somphezulu wokuguguleka lubonisa ukuba ukuguquka kweplastiki yomphezulu we-LLDPE ococekileyo kunzulu kakhulu, kwaye indlela ephambili yokuguguleka kukuguguleka okunamathelayo kunye nokuguguleka. Nangona kunjalo, emva kokongezwa kwe-silicone masterbatch, umphezulu wokuguguleka wezinto ezidityanisiweyo uba mpuluswa, okubangelwa ikakhulu yi-abrasive encinci.

(Olu lwazi, lucatshulwe kwiChina Plastic Industry, Study on Tribological Properties of Modified by Silicone Masterbatch, College of Materials Science and Engineering, University of Liaocheng, China.)

Nangona kunjalo,I-SILIKE LYSI-412I-silicone masterbatch yifomyula eyenziwe ngepellet equlethe ubunzima be-molecular PDMS obuphezulu kakhulu obusasazeke kwi-linear low density polyethylene (LLDPE). Yenzelwe ukusetyenziswa njenge-lubricant additive kwiinkqubo ezihambelana ne-polyethylene ukuze inike iingenelo ezifana neempawu zomphezulu eziphuculweyo (ukuthambisa, ukutyibilika, i-coefficient esezantsi yokungqubana, imvakalelo yesilika).

Ixesha lokuthumela: Juni-30-2021