Kwixesha apho imigangatho nemigaqo yokhuseleko ibaluleke kakhulu, uphuhliso lwezinto ezimelana nokusasazeka komlilo luye lwaba yinto ebalulekileyo kumashishini ahlukeneyo. Phakathi kwezi zinto zintsha, ii-masterbatch compounds ezithintela umlilo ziye zavela njengesisombululo esinobuchule sokuphucula ukumelana nomlilo kwee-polymers.

Ukuqonda Zithini iiFlame Retardant Masterbatch Compounds?

Iikhompawundi ze-masterbatch ezithintela umlilo ziifomyula ezikhethekileyo ezenzelwe ukunika iipolymers iipropati ezimelana nomlilo. Ezi khompawundi ziquka i-carrier resin, edla ngokuba yi-polymer efanayo nezinto ezisisiseko, kunye nezongezo ezithintela umlilo. I-carrier resin isebenza njengendawo yokusasaza ii-agent ezithintela umlilo kuyo yonke i-polymer matrix.

Iinxalenye zeFlame Retardant Masterbatch Compounds:

1. I-Carrier Resin:

I-carrier resin yenza ubukhulu be-masterbatch kwaye ikhethwa ngokusekelwe ekuhambelaneni ne-base polymer. Ii-carrier resin eziqhelekileyo ziquka i-polyethylene (PE), i-polypropylene (PP), i-polyvinyl chloride (PVC), kunye nezinye ii-thermoplastics. Ukukhetha i-carrier resin kubalulekile ukuqinisekisa ukusasazeka okusebenzayo kunye nokuhambelana ne-polymer ekujoliswe kuyo.

2. Izongezo ezithintela ilangatye:

Izongezo ezithintela ilangatye zizithako ezisebenzayo ezinoxanduva lokuthintela okanye lokulibazisa ukusasazeka kwamalangatye. Ngokusisiseko, izinto ezithintela ilangatye zinokuba zezokuvuselela okanye ezongezayo. Ezi zongezo zinokwahlulwa zibe ziindidi ezahlukeneyo, kuquka iikhompawundi ze-halogenated, iikhompawundi ezisekelwe kwi-phosphorus, kunye nezizalisi zeeminerali. Udidi ngalunye lunendlela yalo yokusebenza eyahlukileyo ekuthinteleni inkqubo yokutsha.

2.1 Iikhompawundi zeHalogenated: Iikhompawundi zeBrominated kunye nechlorinated zikhupha ii-halogen radicals ngexesha lokutsha, eziphazamisana nempendulo yetsheyini yokutsha.

2.2 Iikhompawundi ezisekwe kwiPhosphorus: Ezi khompawundi zikhupha i-phosphoric acid okanye i-polyphosphoric acid ngexesha lokutsha, zenze umaleko okhuselayo othintela ilangatye.

2.3 Izizalisi zeMineral: Izizalisi ezingaphiliyo ezifana ne-aluminium hydroxide kunye ne-magnesium hydroxide zikhupha umphunga wamanzi xa zibekwe kubushushu, zipholise izinto kwaye zinyibilikise iigesi ezivuthayo.

3. Izinto zokuzalisa kunye nezinto zokuQinisekisa:

Izithambisi, ezifana ne-talc okanye i-calcium carbonate, zihlala zongezwa ukuphucula iipropati zoomatshini ze-masterbatch compound. Izithambisi zomeleza ukuqina, amandla, kunye nozinzo olulinganayo, okufaka isandla ekusebenzeni ngokubanzi kwezinto.

4. Izinto ezizinzisa umzimba:

Iziqinisi zifakelwe ukuthintela ukuwohloka kwe-polymer matrix ngexesha lokucubungula nokusetyenziswa. Ii-antioxidants kunye neziqinisi ze-UV, umzekelo, zinceda ukugcina ukuthembeka kwento xa ivezwa kwiimeko zokusingqongileyo.

5. Izinto ezifaka imibala kunye neePigments:

Ngokuxhomekeke kwindlela esetyenziswa ngayo, izinto ezifaka imibala kunye nemibala ziyafakwa ukuze zinike imibala ethile kwi-masterbatch compound. Ezi zinto zinokuchaphazela neempawu zobuhle bezinto ezibonakalayo.

6. Izinto ezihambelanayo:

Kwimeko apho i-flame retardant kunye ne-polymer matrix zingabonakalisi ukuhambelana okuhle, kusetyenziswa izixhobo zokuhambelana. Ezi arhente ziphucula ukusebenzisana phakathi kwezinto, zikhuthaza ukusasazeka okungcono kunye nokusebenza ngokubanzi.

7. Izinto ezithintela umsi:

Izinto ezithintela umsi, ezifana ne-zinc borate okanye i-molybdenum compounds, ngamanye amaxesha ziyafakwa ukunciphisa imveliso yomsi ngexesha lokutsha, nto leyo ibalulekileyo ekusetyenzisweni kokhuseleko lomlilo.

8. Izongezo zokuLungiselela:

Izixhobo zokucubungula ezifana nezinto zokuthambisa kunyeiiarhente zokusasazaYenza kube lula inkqubo yokwenziwa kwezinto. Ezi zongezo ziqinisekisa ukucutshungulwa kakuhle, zithintela ukuhlangana kwezinto, kwaye zinceda ekufezekiseni ukusasazeka okufanayo kwezinto ezithintela umlilo.

Ezi zinto zingentla zonke ziyinxalenye yeekhompawundi ze-masterbatch ezithintela umlilo, ngelixa Ukuqinisekisa ukusasazwa ngokulinganayo kwezixhobo ezithintela umlilo ngaphakathi kwi-polymer matrix kuyinto ebalulekileyo ekusebenzeni kwazo. Ukusasazwa okunganelanga kunokukhokelela ekukhuselekeni okungalinganiyo, kwiimpawu zezinto ezinobungozi, kunye nokhuseleko olunciphileyo lomlilo.

Ngoko ke, iikhompawundi ze-masterbatch ezithintela ilangatye zihlala zifunaabasasaziukujongana nemingeni enxulumene nokusasazeka okufanayo kwee-agents ezithintela ilangatye ngaphakathi kwi-polymer matrix.

Ingakumbi Kwicandelo eliguqukayo lesayensi yepolymer, imfuno yezinto eziphucukileyo ezithintela iLangabi ezineempawu zokusebenza ezigqwesileyo ikhuthaze uphuhliso kwizongezo kunye neziguquli. Phakathi kwezisombululo eziqalayo,ii-hyperdispersantsbaye bavela njengabadlali abaphambili, bejongana nemingeni yokufikelela ekusasazekeni ngokugqibeleleyo kwi-Flame Retardant Masterbatch compound formulations.

As ii-hyperdispersantsjongana nalo mceli mngeni ngokukhuthaza ukusasazwa ngokupheleleyo nangokulinganayo kwezinto ezithintela umlilo kuyo yonke indawo ye-masterbatch.

Ngena kwi-Hyperdispersant SILIKE SILIMER 6150—udidi lwezongezo ezitshintsha indlela ezisebenza ngayo izinto ezithintela ilangatye!

I-SILIKE SILIMER 6150, yaphuhliswa ukuze ihlangabezane neemfuno ezahlukeneyo zoshishino lwe-polymer, yi-silicone wax eguquliweyo. Njengesixhoboi-hyperdispersant esebenzayo, inika isisombululo kwimingeni enxulumene nokufikelela ekusasazekeni okufanelekileyo, kwaye ngenxa yoko, ukhuseleko olufanelekileyo lomlilo.

I-SILIKE SILIMER 6150 iyacetyiswa kwiukusasazeka kweepigment kunye nezizalisi zezinto eziphilayo nezingaphiliyo, izinto ezithintela ilangatye kwi-thermoplastic masterbatch, TPE, TPU, ezinye ii-thermoplastic elastomers, kunye nokusetyenziswa kwee-compound. Ingasetyenziswa kwiindidi ezahlukeneyo zee-thermoplastic polymers kuquka i-polyethylene, i-polypropylene, i-polystyrene, i-ABS, kunye ne-PVC.

I-SILIKE SILIMER 6150, Inzuzo ephambili yeekhompawundi ezithintela ilangatye

1. Phucula ukusasazwa okubangela ukuba ilangabi lingasebenzi

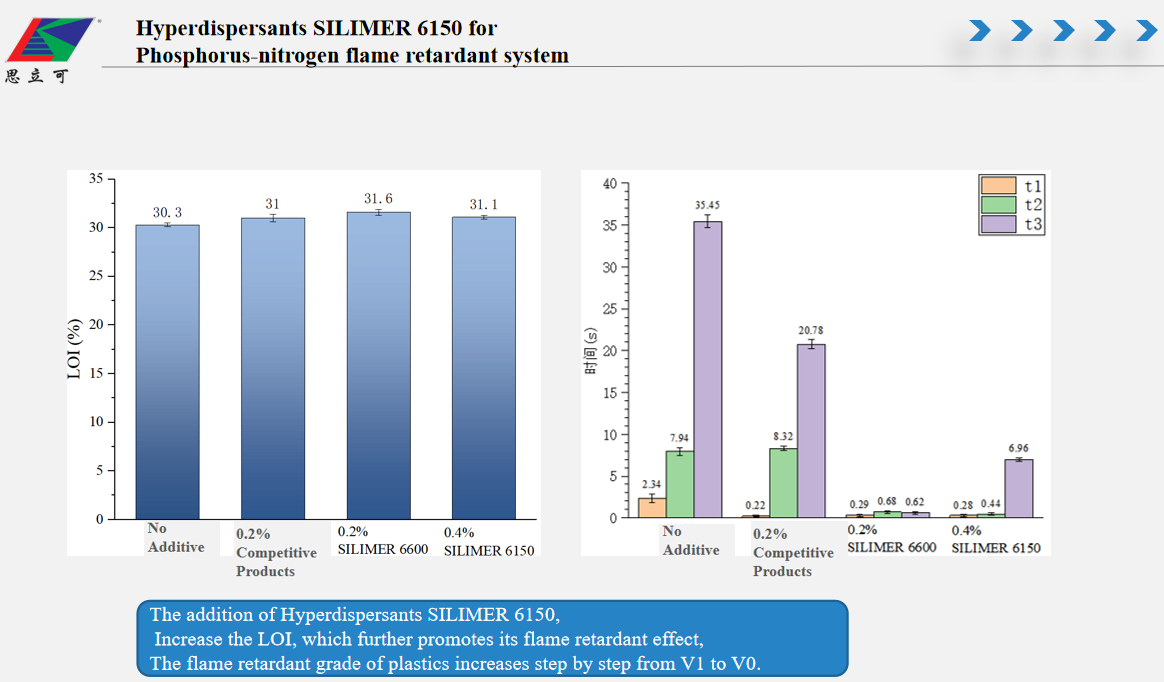

1) I-SILIKE SILIMER 6150 ingasetyenziswa kunye ne-masterbatch ye-phosphorus-nitrogen ethintela ilangatye, iphucula ngempumelelo isiphumo se-flame-retardant ye-flame retardant. Ukwandisa i-LOI, ubungakanani beplastiki ethintela ilangatye buyanda inyathelo ngenyathelo ukusuka kwi-V1 ukuya kwi-V0.

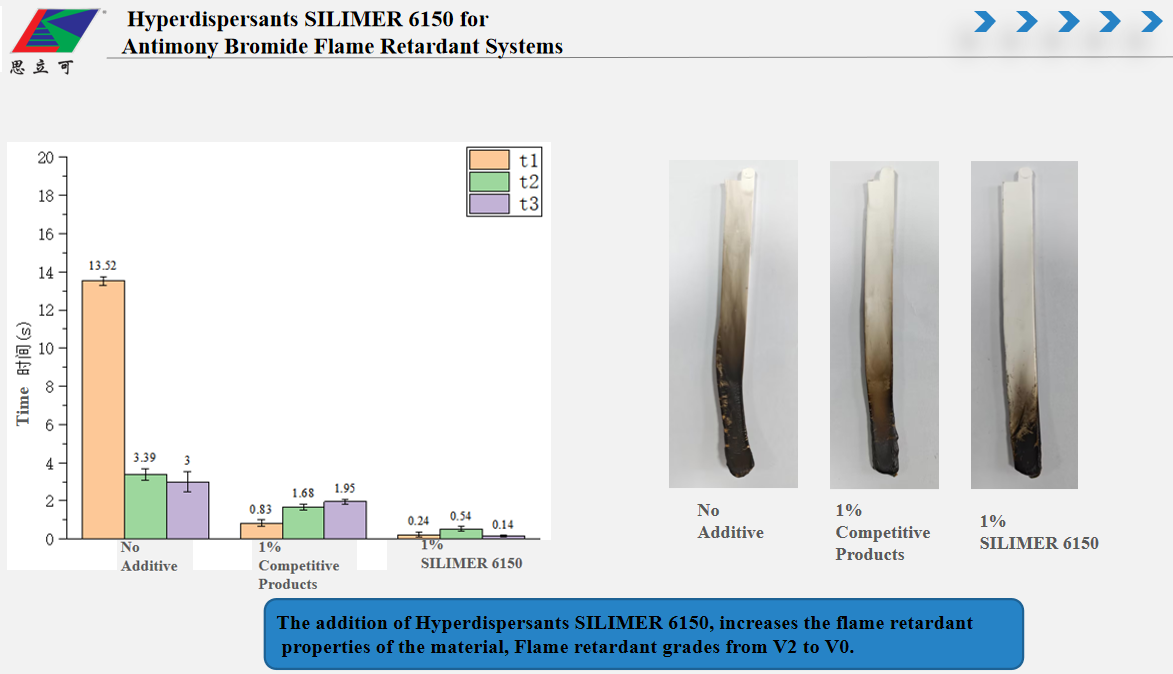

2) I-SILIKE SILIMER 6150 kwaye inentsebenziswano entle yokurhoxisa ilangabi kunye ne-Antimony Bromide Flame Retardant Systems, amazinga okurhoxisa ilangabi ukusuka kwi-V2 ukuya kwi-V0.

2. Phucula ukukhazimla kunye nobuthambile bomphezulu weemveliso (i-COF ephantsi)

3. Amanqanaba okuhamba kokunyibilika okuphuculweyo kunye nokusasazeka kwezizalisi, ukukhululwa ngcono kokubumba kunye nokusebenza kakuhle kokucubungula

4. Ukuphucula amandla ombala, akukho mpembelelo imbi kwiimpawu zoomatshini.

Nxibelelana ne-SILIKE ukuze ubone indlela i-SILIMER 6150 Hyperdispersant enokunceda ngayo abenzi beefomyula ekwenzeni iikhompawundi ezintsha ezithintela ilangatye kunye ne-thermoplastics!

Ixesha lokuthumela: Okthobha-23-2023