Kutheni uKhuseleko loMlilo Luhlala Luyingxaki Ebalulekileyo kwiPlastiki nakwiFibers

Kwimveliso yeplastiki nefayibha yanamhlanje, ukhuseleko emlilweni lungaphezulu nje kwemfuneko yokuthobela imithetho—yinto echaphazela ngqo ukuthembeka kwemveliso kunye nodumo lwegama layo.

Sekunjalo iindlela zemveli zokuthintela umlilo zihlala zidala iingxaki ezintsha: ukusasazwa okungalinganiyo, ukucubungula okunzima, amanqanaba aphezulu okusetyenziswa, kunye nemiphumo emibi kumandla ezinto.

Ii-masterbatches ezithintela ilangatye zikhawuleza zaba yindlela ekhethwayo. Uyilo lwazo oluqinileyo nolusasazekileyo luphucula ukuhambelana, lugcina iipropati zoomatshini, kwaye luxhasa imveliso egudileyo—lunceda abavelisi bahlale bekhuphisana kwiimarike ezifuna kakhulu.

Zithini kanye kanye ii-Masterbatches ezithintela ilangatye?

Ii-masterbatches ezithintela ilangatye zii-concentrates ezongeziweyo ezisebenzayo kakhulu ezenzelwe ukunika i-controlled, i-uniform flame retardancy kwi-polymers. Xa kuthelekiswa ne-loose powders, zibonelela ngezi zinto zilandelayo:

Iingenelo eziPhambili ze-FR Masterbatches

♦ Ukusasazwa okufanayo ukuze kusebenze ngokuzinzileyo okubambezela ilangabi

♦ Iimfuno eziphantsi zedosi, ukunciphisa iindleko zezinto eziphathekayo

♦ Ukuhamba kakuhle kokucubungula kunye nokuphathwa okulula

♦ Impembelelo encinci kwiimpawu zoomatshini

♦ Iindawo zokusebenza ezicocekileyo nezikhuselekileyo ezinothuli oluncinci

Ezi nzuzo zizenza zilungele ukusetyenziswa kwimpahla yokulahlwa, izixhobo zokwakha, izinto zangaphakathi zeemoto, izinto ze-elektroniki, kunye nezinye izinto ezibalulekileyo kukhuseleko.

Iintlobo kunye nezicelo zeFlame Retardant Masterbatches

1. I-Fiber Flame Retardant Masterbatches

1.1 Iifayibha zePolypropylene (PP) zeFiber Masterbatches

Izicelo: Amakhethini, iisofa, iikhaphethi, amabhanti emigodi, amalaphu omoya

Iimpawu: Izinto ezithintela ilangatye ezinoxinzelelo oluphezulu ezidityaniswe nezongezo ezisebenzisanayo kwaye zisontiwe zibe yimicu yokumelana nomlilo ixesha elide

1.2 Iifayibha zePolyester (PET) zeMasterbatches

Izicelo: Amalaphu oshishino, amalaphu okwakha, izinto zangaphakathi zeemoto, impahla yokukhusela

Iimpawu: Ukuthintela ilangatye okuhlala ixesha elide kufanelekile kwiimpahla kunye nokusetyenziswa kwemizi-mveliso

2. Ii-Masterbatches ezithintela ilangatye zeplastiki

2.1 Ii-ABS Masterbatches

Ingxaki: I-ABS iyatsha kakhulu (LOI 18.3–20%)

Isisombululo: Itekhnoloji yeMasterbatch ivumela ukusasazeka ngokulinganayo kwezongezo ze-FR, iphucula ukhuseleko lomlilo ngaphandle kokuphazamisa ukusebenza koomatshini.

2.2 Ii-Masterbatches zePolystyrene ezinefuthe eliphezulu (PS-HI)

Izicelo: Izixhobo zombane, iindawo zeemoto, izixhobo zasekhaya

Iimpawu: Iimeko ezandisiweyo zesicelo kunye nee-masterbatches ezivuthiweyo ezinemisebenzi emininzi (umbala + FR)

2.3 Ii-Polyamide (PA6) Masterbatches

Izicelo: Iiplastiki zobunjineli, izixhobo ze-elektroniki, izixhobo zombane

Iimpawu: Ukuguqulwa kwe-FR kuqinisekisa ukusetyenziswa ngokukhuselekileyo kwizicelo zokusebenza okuphezulu

2.4 Ii-Masterbatches zePolyoxymethylene (POM)

Umngeni: Iipolymers ezinzima ukuzidubula

Isisombululo: Itekhnoloji ye-masterbatch echanekileyo iqinisekisa ukusebenza kwe-FR kwaye igcina amandla oomatshini

Izicelo: Iimoto, izixhobo ze-elektroniki, oomatshini abachanekileyo, izixhobo zokwakha

2.5 IiPolyolefin Masterbatches

Izicelo: Imibhobho, amashiti, iintambo, iindawo zombane, izinto zokuhombisa

Iingenelo: Kulula ukuyisebenzisa, ayibizi kakhulu, iyasebenza kakuhle kakhulu ekucubunguleni

I-SILIKE SILIMER 6600 sisongezelelo se-polymer esisekelwe kwi-silicone, xa sisetyenziswa njenge-dispersant, esijongana nemingeni eqhelekileyo yokusasazeka ejongene nabavelisi be-polymer. Indlela yayo eyahlukileyo yokwenza i-triblock copolymer—edibanisa i-polysiloxane, amaqela e-polar, kunye namaqela e-long carbon chain—inika iziphumo ezibalaseleyo. Ineendlela ezahlukeneyo zokusetyenziswa, kubandakanya ukusasazeka okuthiya ilangabi, ukusasazeka kwe-pigment, kunye nokusasazeka kwe-filler.

I-SILIKE SILIMER 6600 sisongezelelo se-polymer esisekelwe kwi-silicone, xa sisetyenziswa njenge-dispersant, esijongana nemingeni eqhelekileyo yokusasazeka ejongene nabavelisi be-polymer. Indlela yayo eyahlukileyo yokwenza i-triblock copolymer—edibanisa i-polysiloxane, amaqela e-polar, kunye namaqela e-long carbon chain—inika iziphumo ezibalaseleyo. Ineendlela ezahlukeneyo zokusetyenziswa, kubandakanya ukusasazeka okuthiya ilangabi, ukusasazeka kwe-pigment, kunye nokusasazeka kwe-filler.

NjaniIsinyibilikisi seSILIMER 6600Iphucula iiPropati zeFlame Retardant Masterbatches

1. Ukusasazwa Okuphuculweyo Okungasasebenziyo Ngomlilo: Amaqela e-polar kwi-hyperdispersant bond kunye ne-flame retardants, okuqinisekisa ukusasazeka okuzinzileyo, okufanayo kuyo yonke i-polymer matrix.

2. Ithintela ukuphinda kuhlangane: Amacandelo e-polysiloxane agcina ukusasazeka okuzinzileyo nokuba aphantsi kokuchetywa koomatshini, ukuqinisekisa ukuba i-flame retardant ihlala isasazeke ngokulinganayo.

3. Ukuhambelana Okungakumbi Nezixhobo Ezisisiseko: Iitsheyini ezinde zekhabhoni ziqinisekisa ukuhambelana neenkqubo ze-polyolefin, zithintela ukufuduka okanye ukuphuma kwezinto ezithintela ilangatye ngexesha lokucubungula.

Iingenelo eziphambili zeiarhente yokusasazaI-SILIMER 6600 yeeNkqubo ezithintela ilangatye

♦Ukusasazwa okuphuculweyo →ukusebenza okuphezulu okubambezela ilangabi

♦Igcina iipropati zoomatshini →ukusebenza ngcono kokuxinana kunye nokwandiswa

♦Ithintela ukuhlangana kwamasuntswana e-FR →uzinzo oluhambelanayo

♦Ubuhlobo obuhle kakhulu be-polyolefin →ukufuduka okuncitshisiweyo

♦Isiphumo sokuthambisa →ukukhupha okugudileyo kunye nokuphucula amandla okukhupha

IsiceloUphononongo kwiNkqubo ye-Frosphorus-Nitrogen FR ethintela ilangabi

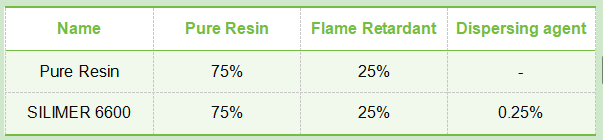

1. Indlela Yokulungiselela

I-Flame Retardant: I-Phosphorus–Nitrogen flame retardant

Indlela Yokulungiselela: I-flame retardant yanyangwa nge-dispersant, yaze yaxutywa ngqo ne-resin ukwenza ii-pellets → I-injection molding ukulungiselela iisampulu zovavanyo → Uvavanyo lokusebenza

2. Ukwenziwa kovavanyo

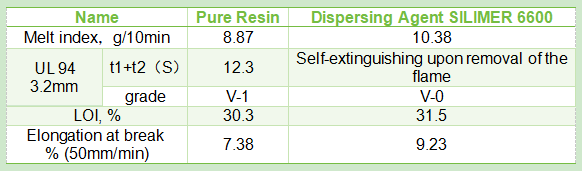

3. Idatha yoVavanyo

4. Isiphelo sovavanyo

Ukongeza i-SILIMER 6600 kuphucule kakhulu ukusasazwa kwamasuntswana e-FR, nto leyo ekhokelele koku:

♦Ukuthintela ilangatye okungcono

♦Ukuphucuka okuphakathi kobude ngexesha lokuphumla

♦Ukuhamba kokucubungula okuphuculweyo kunye nokuzinza kokubumba

Oku kuqinisekisa ukuba i-SILIMER 6600 iphucula zombini ngempumeleloukusebenzakwayeukuqhubekekakwiinkqubo zepolymer ezisekelwe kwi-FR.

Kutheni Abavelisi Bekhetha ii-FR Masterbatches +Isisasazi seMisebenzi emininzi iSILIMER 6600

Olu dibaniselwano lunika abavelisi ithuba elibonakalayo lokukhuphisana:

♦Ukuthintela ilangatye okuphezulu

♦Iimpawu zoomatshini ezizinzileyo

♦Ukusebenza kakuhle kwemveliso

♦Umlinganiselo oncitshisiweyo kunye neendleko eziphantsi

Vula Ukusebenza Okungcono kwe-FR Ngokusasazwa Okungcono

Ii-masterbatches ezithintela ilangatye ezidityaniswe ne-SILIMER 6600 zibonelela ngesisombululo sanamhlanje nesisebenzayo sokuphucula ukhuseleko, ukucubungula, kunye nomgangatho wezinto eziphathekayo. Njengoko imigangatho yoshishino isiya iqina, ukuphucula ukusasazwa akusekho mfuneko—kubalulekile.

Ngaba ufuna isikhokelo sengcali kwisicelo sakho?

I-SILIKE inikezela ngeengcebiso ezenzelwe wena:

♦Ezinye izongezo ze-silicone ezisebenzayo ezininzikwiinkqubo zepolymer ezisebenzayo kakhulu

Nokuba uphucula ukumelana nelangatye lefayibha, uphuhlisa izixhobo ze-elektroniki ezikhuselekileyo, okanye uphucula iifomyula ze-polyolefin, iqela lethu linokukunceda ukhethe indlela efanelekileyo.

Nxibelelana no-Amy Wang aphaamy.wang@silike.cnokanye undwendwele i-www.siliketech.com ukuze ufumane izisombululo ze-polymer processing additives ezithintela ilangatye.

Ixesha leposi: Novemba-14-2025