Izithako zoLungiso lwePolymer (PPA) ligama eliqhelekileyo leentlobo ezahlukeneyo zezinto ezisetyenziselwa ukuphucula iipropati zokucubungula nokuphatha iipolymers, ikakhulu kwimeko enyibilikisiweyo ye-polymer matrix ukuze zidlale indima. Ii-Fluoropolymers kunye nezixhobo zokulungisa i-polymer ze-silicone resin zisetyenziswa kakhulu kwi-polyolefin polymers.

I-PPA ingafakwa kwizinto eziquka i-LLDPE, i-LDPE, i-HDPE, i-MDPE, i-PP, ii-elastomers ze-thermoplastic, i-PS, i-nylon, ii-acrylic resins, i-PVC njalo njalo. Iindawo zokusetyenziswa zingaba yifilimu evuthuzayo, i-cast extrusion, ucingo kunye nentambo, i-pipe kunye ne-sheet extrusion, i-masterbatch processing, i-hollow blow molding, njalo njalo.

Indima ephambili yePolymer Processing Aid (PPA) kwimveliso kunye nokucubungula ucingo kunye neentambo kukuphucula ukusebenza kokucubungula ipolymer kunye nomgangatho wemveliso. Ezi zilandelayo zezinye zezizathu eziphambili zokongeza iPPA:

1. Ukuncipha kobumanzi obunyibilikayo: I-PPA inokunciphisa i-melt viscosity yee-polymers, yenze kube lula ukuhamba ngexesha lokucubungula kunye nokuphucula isantya sokukhupha kunye nemveliso.

2. Inkangeleko yeMveliso ephuculweyo: I-PPA inokuphucula ukukhazimla komphezulu kunye nokuthamba kweemveliso zentambo kunye neentambo, inciphise iziphene kunye nokungafezeki kwembonakalo, kwaye iphucule ubuhle kunye nexabiso lemveliso.

3. Nciphisa ukusetyenziswa kwamandla: Ekubeni i-PPA inciphisa i-melt viscosity ye-polymer, amaqondo obushushu aphantsi okucubungula, kunye noxinzelelo ziyafuneka ngexesha lokukhupha, ngaloo ndlela kunciphisa ukusetyenziswa kwamandla kunye neendleko.

4. Uzinzo oluphuculweyo lwe-extrusion: Ukongezwa kwe-PPA kuphucula ukuhamba kunye nokuzinza kokunyibilika kwepolymer, kunciphisa ukutshintshwa kokuphuma kunye nokuwohloka ngexesha lokukhutshwa, okubangela imveliso ezinzileyo ngakumbi ngokobukhulu kunye nomgangatho.

Ngokubanzi, ukongezwa kwe-polymer processing kunceda i-PPA ukuphucula imveliso kunye nokusebenza kwe-wire kunye ne-cable, kunye nokuphucula umgangatho kunye nokusebenza kakuhle kwemveliso. Kodwa ngenxa yokuvalwa okucetywayo kwe-fluoride, ukufumana ezinye iindlela endaweni ye-fluorinated PPA kube ngumceli mngeni omtsha.

Ukulungisa le ngxaki, i-SILIKE iziseEnye indlela engena-PTFEukuya kwi-PPA esekelwe kwiFluorine ——isongezo sokucubungula i-polymer esingena-PFAS (i-PPA)OkuI-PPA MB engenafluorine, Isongezelelo esingena-PTFEyi-polysiloxane masterbatch eguqulwe ngokwendalo esebenzisa isiphumo esihle kakhulu sokuthambisa sokuqala se-polysiloxanes kunye ne-polarity yamaqela aguqulweyo ukufuduka nokusebenza kwizixhobo zokucubungula ngexesha lokucubungula.

Izixhobo zokulungisa iipolymer ezingenayo i-PFAS (i-PPA)——ukunceda ukuveliswa kweengcingo kunye neentambo ukuba kube nempumelelo ngakumbi >>

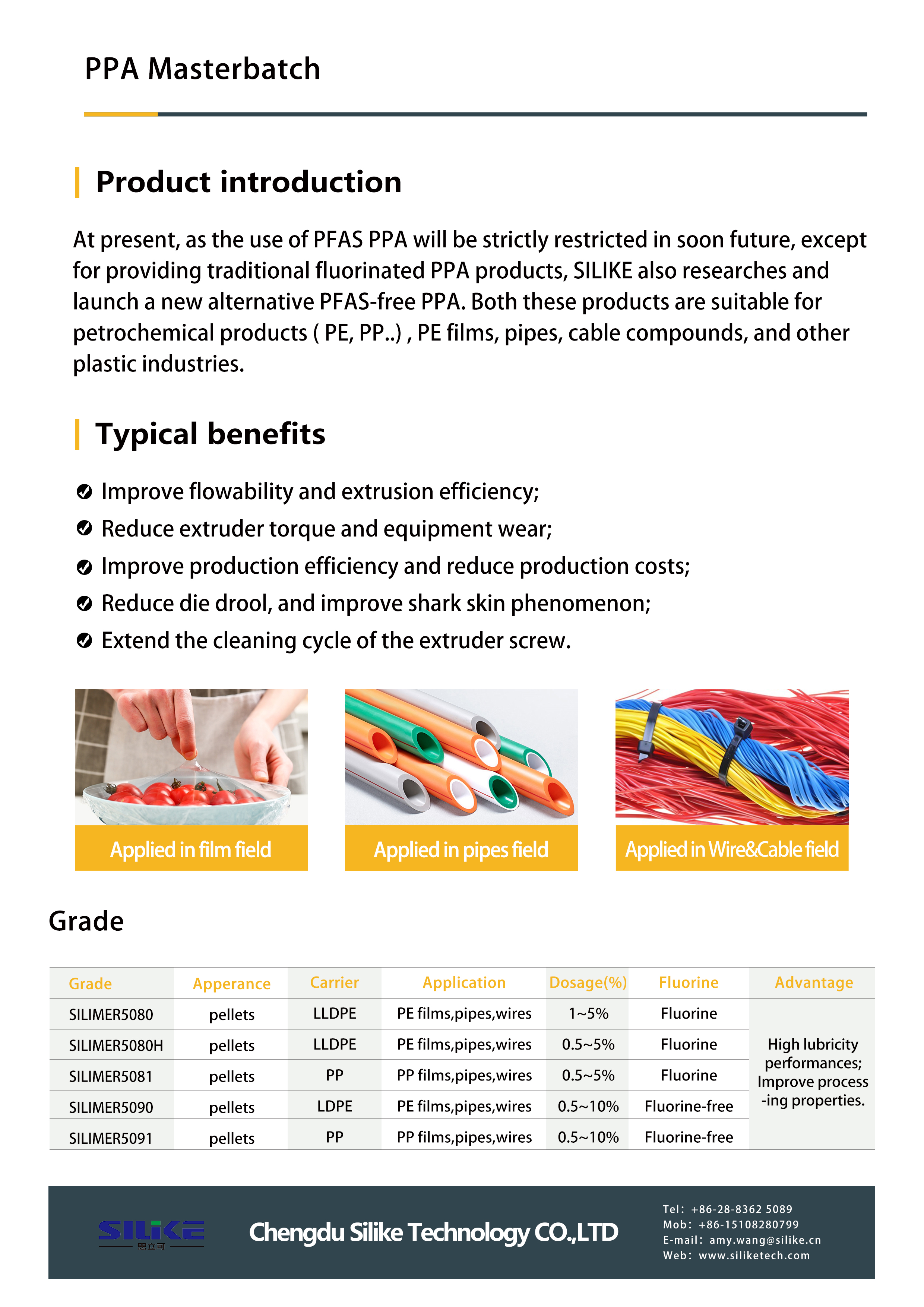

I-SILIKE iphuhlisa i-PPA engena-fluorine njengendawo efanelekileyo yokutshintsha izixhobo zokucubungula i-PPA ene-fluorine, ukongeza okuncinci kwe-I-SILIKE SILIMER-5090 I-non-fluoropolymer processing additiveIphucula ukusebenza kokucubungula ucingo kunye neentambo. Inciphisa ngokufanelekileyo uxinzelelo lweentloko ze-die, iphucula uzinzo lwe-extrusion, inciphisa i-extrusion pulsation, isusa ukwakheka kweentloko ze-die, iphucula kakhulu ukutyibilika kwe-processing, inciphisa i-torque kwaye iphucula imveliso. Iphucula umgangatho womphezulu kunye nokuguda kweemveliso.

Izixhobo zokulungisa iipolymer ezingenayo i-SILIKE PFAS (PPAS)Zineentlobo ngeentlobo zezicelo zeentambo, iifilimu, iityhubhu, ii-masterbatches, ingca yokwenziwa, njl.

Ukusebenza okuqhelekileyo:

Ukuphuculwa kobuchule bokusebenza

Ukuthambisa kunye nokusasazeka okusebenzayo

Ukuphuculwa kokusebenza kakuhle kokucubungula

Iphelisa ukwaphuka kokunyibilika

Inciphisa ukuvuza kwamanzi kunye nokwakheka kwamanzi

Apha ngezantsi kukho amanqanaba acetyiswayo e-Izixhobo zokucubungula i-SILIKE PPA, ungazijonga. Ukuba unemibuzo, nceda ungathandabuzi ukundifowunela. I-SILIKE ijonge phambili ekukunikeni ulwaziizisombululo ze-PPA engenafluorine kwizicelo zentambo kunye neentambo.

Ixesha lokuthumela: Novemba-10-2023