I-polyamide resin, efinyeziweyo njenge-PA, yaziwa kakhulu ngokuba yi-nylon. Yiyunithi ephindaphindayo ye-macromolecular main chain equlathe amaqela e-amide kwi-polymer yegama eliqhelekileyo. Iiplastiki ezintlanu zobunjineli kwimveliso enkulu, iintlobo ezininzi, iintlobo ezisetyenziswa kakhulu, kunye nezinye ii-polymer blends kunye ne-alloys, njl.njl., ziyahlangabezana neemfuno ezikhethekileyo ezahlukeneyo, ezisetyenziswa kakhulu endaweni yesinyithi, umthi, kunye nezinye izinto zemveli.

I-PA6 yinto eyenziwe nge-nylon, enamandla oomatshini aphezulu kodwa angaphantsi kune-PA66; amandla okuxinana, ubulukhuni bomphezulu, kunye nokuqina kuphezulu kunezinye iiplastiki ze-nylon, kwaye ukumelana nempembelelo kunye nokuguquguquka kune-PA66.

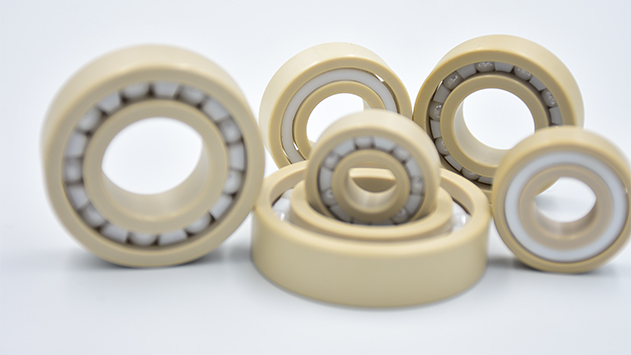

Imveliso yeplastiki ye-PA6 nylon yemizi-mveliso isetyenziswa kakhulu ekwenzeni iibheringi, iigiya ezijikelezileyo, iikhamera, iigiya ze-bevel, iintlobo ngeentlobo zeerola, iipulley, ii-pump impellers, ii-fan blades, ii-worm gears, ii-propellers, ii-screws, ii-nuts, ii-gaskets, ii-seals ezixinzelelekileyo, ii-gaskets ezinganyangekiyo kwi-oyile, izikhongozeli ezinganyangekiyo kwi-oyile, ii-housings, ii-hoses, ii-cable sheathing, kunye nezinto ezifunekayo zemihla ngemihla kunye nefilimu yokupakisha njalo njalo.

I-PA6 isetyenziswa kakhulu ekubumbeni ngenaliti, ekubumbeni nge-extrusion, nakwezinye iindlela zokucubungula. Ngexesha lokucubungula, i-PA6 inokuba neengxaki ezifanayo, kuquka:

Ukuhamba kakuhle kokunyibilika: I-PA6 inoburhabaxa obukhulu bokunyibilika, nto leyo ekhokelela ngokulula ekungahambeni kakuhle kokunyibilika kwaye ichaphazela umgangatho wokubumba kwemveliso. Ukunyibilika kolwelo kunokuphuculwa ngokulungelelanisa ubushushu bokucubungula kunye nokunyusa uxinzelelo lwenaliti.

Ukuncipha okukhulu: I-PA6 iya kuba nokuncipha okukhulu kwinkqubo yokupholisa, nto leyo eya kukhokelela ngokulula kubungakanani bemveliso obungazinzanga okanye ukuguquguquka. Ukuncipha kunokuncitshiswa ngokuyila ngokwengqiqo isakhiwo sokubumba nokulawula isantya sokupholisa.

Amaqamza kunye nemingxunya: Kwi-injection molding, i-PA6 inokuvelisa amaqamza kunye ne-porosity ngenxa ye-gas residue okanye ukuhamba kakuhle kokunyibilika, okuchaphazela umgangatho womphezulu wemveliso. Ukuveliswa kwamaqamza kunye ne-porosity kunokunciphisa ngokuphucula ulwakhiwo lwe-mold kunye nokunyusa ubushushu bokunyibilika.

Ukumelana nokuguguleka komphezulu: I-PA6 idla ngokukrweleka ngexesha lokubumba okanye ukukhupha i-injection, nto leyo echaphazela umgangatho wemveliso kwaye ngaloo ndlela inciphisa ubomi benkonzo yemveliso. Kwi-PA6 pelleting processing inokongeza ubungakanani obufanelekileyo bei-masterbatch yesilicone, ngokuguqulwa kwezinto ze-PA6, ukuphucula ukusebenza kokucubungula kwamasuntswana e-PA6, ukuphepha umgangatho weemveliso ezichaphazelekileyo.

Ukumelana nokuguguleka komphezulu we-SILIKE Silicone Masterbatch——Ukunceda uphuhliso lweshishini lobunjineli beplastiki

I-SILIKE Silicone Masterbatch I-LYSI-407yifomyula eyenziwe ngepellet ene-30% ye-molecular weight siloxane polymer esasazeke kwi-Polyamide-6 (PA6). Isetyenziswa kakhulu njengesongezelelo esisebenzayo kwiinkqubo ze-resin ezihambelana ne-PA6 ukuphucula iipropati zokucubungula kunye nomgangatho womphezulu, ezifana nokukwazi ukuhamba kwe-resin okungcono, ukuzaliswa kunye nokukhululwa kwesikhunta, i-torque encinci ye-extruder, i-coefficient ephantsi yokungqubana, kunye nokumelana okukhulu kwe-mar kunye ne-abrasion.

Zithini iingenelo zokongeza isixa esifanelekileyo seI-SILIKEI-Silicone Masterbatch LYSI-407kwinkqubo ye-granulation?

(1) Ukuphucula iipropati zokucubungula kuquka ukukwazi ukuhamba kakuhle, ukuthontsiza okuncitshisiweyo kwe-extrusion die, i-torque encinci ye-extruder, ukuzaliswa kunye nokukhululwa okungcono kwe-molding

(2) Phucula umgangatho womphezulu njengokutyibilika komphezulu kunye neCoefficient ephantsi yokungqubana.

(3) Ukumelana nokukrweleka okukhulu kunye nokukrweleka

(4) Ukuphuma ngokukhawuleza, kunciphisa izinga lokungasebenzi kakuhle kwemveliso.

(5) Yomeleza uzinzo xa kuthelekiswa nezixhobo zokucubungula zemveli okanye izinto zokuthambisa

Zeziphi iindawo zokusetyenziswa kweI-SILIKE Silicone Masterbatch LYSI-407?

(1) iikhompawundi ze-PA6, PA66

(2) Iikhompawundi ze-PA zefayibha yeglasi

(3) Iiplastiki zobunjineli

(4) Ezinye iinkqubo ezihambelana ne-PA

I-SILIKE LYSI series silicone masterbatchIngacutshungulwa ngendlela efanayo ne-resin carrier apho isekelwe khona. Ingasetyenziswa kwiinkqubo zokuxuba i-melt zakudala ezifana nee-Single / Twin screw extruders, kunye ne-injection molding. Kucetyiswa umxube ophathekayo kunye nee-virgin polymer pellets.

Ubungakanani obuhlukeneyo bokongeza bunemiphumo eyahlukileyo, ukuba ufuna ukuphucula ukusebenza kokucubungula kunye nokusebenza komphezulu wezinto zobunjineli zeplastiki, ungaqhagamshelana ne-SILIKE, kwaye singakunika izisombululo ezisebenzayo zokwenza iimveliso zakho zikhuphisane ngakumbi.

Tel: +86-28-83625089/+ 86-15108280799 Email: amy.wang@silike.cn

Iwebhusayithi:www.siliketech.com

Ixesha leposi: Matshi-07-2024