Ungazisombulula njani iingongoma zentlungu zokucubungula izixhobo zekhebula ezingenamsi ophantsi we-halogen?

I-LSZH imele ii-halogens ezingenanto yomsi ophantsi, ezingenamsi ophantsi, olu hlobo lwentambo kunye nocingo lukhupha umsi omncinci kakhulu kwaye alukhuphi ii-halogens ezinetyhefu xa luvezwa kubushushu. Nangona kunjalo, Ukuze kufezekiswe ezi zinto zimbini zibalulekileyo, ekuvelisweni kwezinto zentambo ezingenamsi ophantsi, ii-halogens ezingenanto yomsi ophantsi (LSZH) zilayishwa kakhulu, nto leyo ekhokelela ngokuthe ngqo kwiimpawu zoomatshini nezokucubungula.

Ubunzima ekucutshungulweni kwezinto ezingenayo i-halogen enomsi omncinci:

1. Ifomyula eqhelekileyo, iikhompawundi zentambo ze-LSZH polyolefin ezizaliswe ngomxholo ophezulu ziqulathe ukuya kuthi ga kwi-55-70% ATH/MDH, Njengoko inani elikhulu le-aluminium hydroxide, i-magnesium hydroxide, kunye nezinye izinto ezithintela ilangatye ukuze zijoyine ukusetyenziswa kwenkqubo yokuhambahamba kakubi, ukuveliswa kobushushu obunokungqubana ngexesha lokucubungula kukhokelela ekwandeni kobushushu okubangela ukonakala kwe-aluminium kunye ne-magnesium hydroxide.

2. Ukusebenza kakuhle kwe-extrusion ephantsi, nokuba uyandisa isantya se-extrusion volume kuhlala kufana.

3. Ukuhambelana okungekho semgangathweni kwezinto ezithintela ilangatye ezingaphiliyo kunye nezizalisi kunye ne-polyolefins, ukusasazwa okungekho semgangathweni ngexesha lokucubungula, okubangela ukwehla kweempawu zoomatshini.

4. Umphezulu orhabaxa kunye nokungabikho kokukhanya ngexesha lokuphuma ngenxa yokusasazeka okungalinganiyo kwezinto ezithintela ilangatye ezingaphiliyo kwinkqubo.

5.I-polarity yesakhiwo sezinto ezithintela ilangatye kunye nezizalisi ibangela ukuba ukunyibilika kunamathele kwintloko yesikhunta, nto leyo ebambezela ukukhululwa kwezinto kwisikhunta, okanye iimolekyuli ezincinci kwifomyula ziphume, nto leyo ebangela ukuqokelelana kwezinto kwindawo yokuvula isikhunta, nto leyo echaphazela umgangatho wentambo.

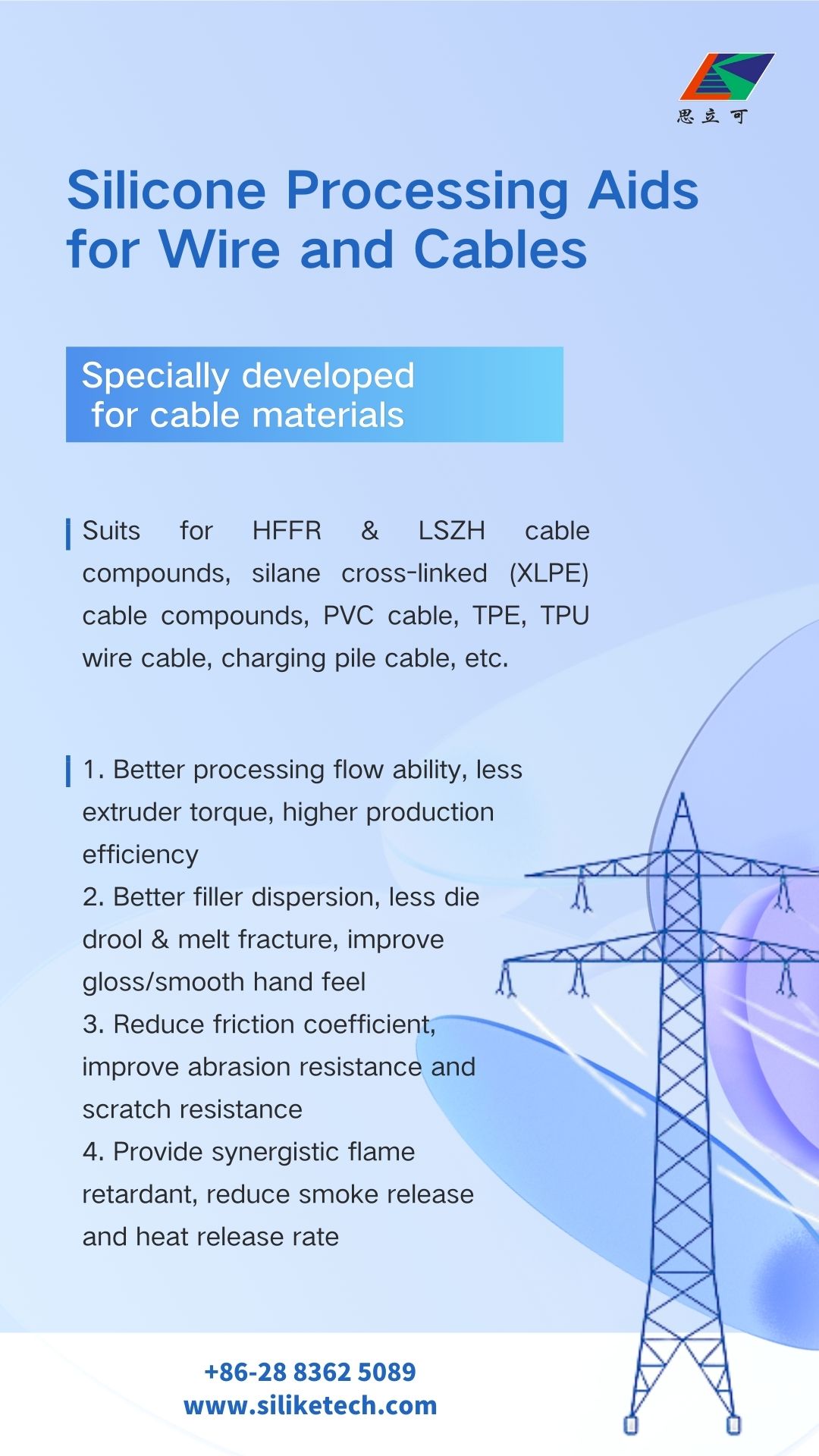

Ngokusekelwe kwimiba engentla, i-SILIKE iphuhlise uthotho lweisongezo se-siliconeiimveliso ezenzelwe ngokukodwa ukujongana neemeko ezinzima zokucubungula kunye nomgangatho womphezulu wezixhobo zekhebula ezingenamsi uphantsi we-halogen, iikhompawundi zentambo kunye neentambo ezingenamsi uphantsi, okanye ezinye iikhompawundi zePolyolefin ezizaliswe ziiminerali ezininzi zokusetyenziswa kweentambo kunye neentambo, zibonelela ngezisombululo ezahlukeneyo ezisebenzayo kwezi ngxaki.

Umz.:I-Silicone Masterbatch (iSiloxane Masterbatch) LYSI-401yifomyula eyenziwe ngepellet ene-50% ye-molecular weight siloxane polymer esasazeke kwi-low-density polyethylene (LDPE). Isetyenziswa kakhulu njenge-processing additive esebenzayo kwiinkqubo ze-resin ezihambelana ne-PE ukuphucula iipropati zokucubungula kunye nokuguqula umgangatho womphezulu.

Ukongeza i-0.5-2% yeI-SILIKE silicone masterbatch LYSI-401Kwinkqubo yokuzalisa ethintela ilangatye ephezulu, ii-wire & cable compounds ezingenanto yomsi ophantsi okanye ii-halogens ezingenanto yomsi ophantsi (LSZH) izixhobo zekhebula zivumela abenzi beentambo kunye neentambo ukuba bandise imveliso, banokuphucula ukutyibilika kokucubungula, banciphise i-torque, bakhawulezise isantya somphezulu ngaphandle kokufuduka, baphucule umgangatho womphezulu wentambo kunye neentambo, (i-coefficient ephantsi yokungqubana, ukukrwela okuphuculweyo kunye nokumelana nokuguguleka, ukutyibilika okungcono komphezulu, kunye nokuziva kwesandla ...) ngaphandle kokuhlawula iprimiyamu yezongezo zokusebenza ezingadingekiyo.

Ngokwesiqhelo, kwi-Ordinaryi-masterbatch yesilicone, i-siloxane ayisiyo-polar, kwaye uninzi lweeparamitha zokunyibilika kwe-carbon chain polymer zomahluko zikhulu kakhulu, ukongezwa kwenani elikhulu lamatyala kunokukhokelela ekucutshungulweni kokutyibilika kwezikrufu, ukuthambisa okugqithisileyo, ukususwa komphezulu wemveliso, okuchaphazela umphezulu weemveliso zeempawu zokubopha zeemveliso kwi-substrate ezisasazeke ngokungalinganiyo njl.njl.

Ngelixa,Izongezo ze-silicone ezinobunzima obukhulu kakhulu be-molecular ze-SILIKEziguqulwa ngamaqela akhethekileyo, anokukhethwa kwaye ahambelane ngokweemfuno ezahlukeneyo zezithako ze-silicone kwi-substrates ezahlukeneyo. Olu luhlu lweemveliso lungadlala indima yokubambelela kwi-substrate, ngaloo ndlela luhambelana ngcono ne-substrate, lusasazeke lula, luqine ngakumbi, kwaye ngaloo ndlela lunike i-substrate ukusebenza okugqwesileyo. Xa isetyenziswa kwiinkqubo ze-LZSH kunye ne-HFFR, inokukuphepha ngokufanelekileyo ukutyibilika kwezikrufu kwaye ikwadlala indima ebalulekileyo ekuphuculeni ukuqokelelwa kwezinto kwisikhunta somlomo.

Ixesha lokuthumela: Sep-07-2023