Intshayelelo: Umngeni weeJacket zeTPU Cable

Iijakethi zekhebula zeTPU zisetyenziswa kakhulu kwii-elektroniki zabathengi, izixhobo ezinxitywayo, kunye neentambo zemizi-mveliso, zibonelela ngokuguquguquka, ukuqina, kunye nobuhle obuthambileyo. Nangona kunjalo, abavelisi badla ngokujongana nemingeni engapheliyo:

→ Imiphezulu engacwebezeliyo iyakhazimla emva kokukhupha

→ Ukukrweleka okuncinci okubonakala ngexesha lokusonga okanye ukusetyenziswa kwemihla ngemihla

→ Ukuchuma okanye ukuna kwemvula okongezayo kunciphisa umgangatho womphezulu

→ Ubunzima bokulinganisela inkangeleko yomphezulu, ukumelana nokuguguleka, kunye nokusebenza kakuhle kwenkqubo

→ Ukufikelela kwisiphelo esizinzileyo se-matte ngelixa ugcina ukukrwela kunye nokumelana nokuguguleka yeyona nto iphambili kwiinjineli ze-R&D kwimveliso yeentambo.

Iinjineli ze-TPU kunye nee-compound formulators ze-TPU zihlala zikhangela izisombululo kwimibuzo efana nale:

Ungayiphucula njani impembelelo ye-matte kwiikhompawundi ze-TPU?

Zeziphi izongezo ezongeza ukuxhathisa ukukrwela ngaphandle kokuchaphazela ukugqitywa komphezulu?

Kutheni iijakethi zekhebula zeTPU ziqhakaza ngokuhamba kwexesha?

Ungayifumana njani indawo eqinileyo ye-matte kwizicelo ze-TPU ezisebenza kakuhle?

I-SILIKE Matt Effect Masterbatch — Isisombululo Esisebenza Kakhulu See-TPU Compounds KwiiCable Jackets

I-SILIKE Matte Effect Masterbatch 3135sisithako esisebenzayo esisemgangathweni esixabisekileyo esenziwe ngeTPU njengesithwali.imattifier ephucukileyoiphucula imbonakalo ye-matte, ubume bomphezulu, ukuqina, kunye neempawu zokuchasana nokuvimba kwee-TPU composites kunye neemveliso ezigqityiweyo, ngakumbi kwiijakethi zekhebula, iifilimu, kunye nezinye izinto ezisetyenziswayo.

Iimbalasane zeArhente yeMatting esebenza kakhulu kwiiJacket zeTable zeTPU

1. Ukuchukumisa okuthambileyo okusilika – Kubonelela ngamava afanelekileyo okuchukumisa.

2. Ukumelana nokuGqoka nokuKrwela – Iphucula ukuqina komphezulu phantsi koxinzelelo loomatshini.

3. Ukugqitywa kweMatte okuQinisekileyo – Igcina inkangeleko ecocekileyo ye-matte ukusuka kwimveliso ukuya ekusetyenzisweni kwayo ekugqibeleni.

3. Akukho mvula – Ithintela ukudumba kunye nokufuduka kwezityalo, iqinisekisa ukuba iindawo ezihlala zicocekile ixesha elide.

Izisombululo zeTPU zeMigaqo yoBugcisa-isiphumo seMatte kwizicelo zekhebula

I-SILIKE TPU Matt Masterbatch isebenzisa ubunjineli bomphezulu obuguqulwe yi-silicone, iphucula i-micro-surface topology kunye ne-friction coefficient. Olu tshintsho luqinisekisa ukuba i-TPU matrix igcina:

Ukunyaniseka komphezulu ngexesha lokukhupha kunye nokugoba

Ubuhle obuthambileyo ngaphandle kokuphazamisa amandla oomatshini

Ukubonakala kwe-matte yexesha elide nokuba kuphantsi koxinzelelo lobushushu okanye loomatshini

Isikhokelo sesicelo seefomyula zekhebula zeTPU: Ukulungiswa koMphezulu weTPU okuSebenza ngokuPhezulu

→Isikhokelo sokuQulunqwa kwe-TPU Soft-Touch Matte - Iingcebiso eziqhelekileyo zokusetyenziswa:

Umlinganiselo: Ulungiselelwe ngokwenqanaba le-TPU kunye nenkqubo yokukhupha (ngesiqhelo yi-1–10 wt%).

Indlela Yokuxuba: Ukuxuba okomileyo okanye ukuxuba kwangaphambili ngee-TPU pellets ukuqinisekisa ukusasazwa okufanayo.

→Iingcebiso Zokucubungula Ukuphucula Ukucubungula kwe-TPU kunye nokubonakala komphezulu:

Gcina ubushushu obungaguqukiyo bokunyibilika ukuze kuthintelwe ukutshintshatshintsha kwe-gloss yomphezulu.

Lungisa isantya sesikrufu ukuze unciphise imikrwelo emincinci.

Uphononongo lweTyala lweejakethi zekhebula zeTPU ezingakhuliyo kwaye ezingakrweliyo

Iijakethi zekhebula zeTPU ezidityaniswe nee-SILIKE Matting Agents zeTPU zigcine ukugqitywa okuqinileyo okungaguquguqukiyo kunye nokuchukumisa okuthambileyo emva kweenyanga ezi-6 zovavanyo oluqhubekayo lwasentsimini, ngaphandle kokuqhakaza kunye nokumelana nokuguguleka okuphuculweyo.

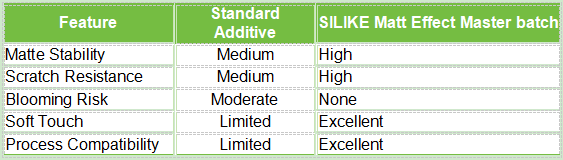

Ukuthelekiswa kweMatt Effect Masterbatch nezinye izongezo

I-SILIKEI-Matte Effect MasterbatchAyisombululi nje kuphela iingxaki eziqhelekileyo zokuzinza kwe-matte kunye nokukrwela kodwa ikwaqinisekisa ukusebenza kakuhle kwenkqubo kunye nobuhle bemveliso.

Imibuzo Ebuzwa Rhoqo: Ungayilungisa njani i-TPU Matte Formulations?

Q1: Ungakuthintela njani ukutyibilika kwe-gloss kwiijakethi zekhebula ze-TPU?

A1: Sebenzisa i-SIIKE TPU based Matte Effect Masterbatch ukuzinzisa isakhiwo somphezulu kunye nokunciphisa ukungqubana ngexesha lokukhupha.

Umbuzo 2: Kutheni le nto imiphezulu ye-TPU matte idubula okanye ibonise amabala amhlophe?

A2: Ukuqhakaza kudla ngokubangelwa kukuhamba kwezinto ezongeziweyo okanye iioyile ezingahambelaniyo. I-Matt Flatting Agent eyenziwe kakuhle iqinisekisa ukugqunywa kunye nozinzo.

Q3: Ungayonyusa njani ukumelana nokukrwela ngaphandle kokulahlekelwa yi-matte finish?

A3: Faka ii-micro-particles ezingagugiyo ngaphakathi kwe-masterbatch eguqulwe yi-silicone ukuze kulinganiswe ukunciphisa ukungqubana kunye nobuhle obungabonakaliyo.

Q4: Ithini idosi ecetyiswayo ye-SILIKE Matt Effect Masterbatch?

A4: Ngokwesiqhelo yi-1–10 wt% ngokuxhomekeke kudidi lwe-TPU kunye nesiphumo se-matte esifunekayo. Ukudibanisa kwangaphambili kuqinisekisa ukusasazwa okufanayo.

Umbuzo 5: Ngaba le masterbatch ye-Anti-blocking Matt Effect ingasetyenziswa kwi-extrusion ekhawulezayo kwiijakethi zekhebula?

A5: Ewe. Yenzelwe ukugcina umphezulu uhambelana kwaye iphephe iziphene nokuba iphantsi koxinzelelo oluphezulu lobushushu.

Ukuphucula iifomyula ze-TPU compound ukuze zisebenze kakuhle, zingagugi, kwaye zingabi nasiphako. Nge-SILIKE Matt Effect Masterbatch, iinjineli ze-R&D kunye nabavelisi beentambo banokufezekisa oku kulandelayo:

√ Umphezulu ozinzileyo ongamatte ukusuka kwimveliso ukuya ekusetyenzisweni kwayo kokugqibela

√ Ukumelana nokukrweleka nokuguguleka okwandisiweyo

√ Ukuthintela ixesha elide ukudumba kunye nemvula eyongezelelweyo

Ngaba unomdla wokuphucula iifomyula zakho zekhebula zeTPU? Nxibelelana ne-SILIKEUmvelisi weMatt Effect Masterbatchukucela isampulu yasimahla okanye ingcebiso yobugcisa kunye namava namava eendawo ze-TPU ezimatte ezisebenza kakuhle, kunye neendlela zokuguqula umphezulu we-TPU kwiifowuni.

Please Reach Amy Wang at amy.wang@silike.cn or visit www.siliketech.comngenxaisisombululo sokwenziwa kwe-TPU esiqinileyo se-matte esiqinileyo

Ixesha leposi: Novemba-26-2025