Ngaba ujongene neTorque ephezulu, iDie Drool, okanye ukuhamba kakubi kwee-LSZH Cable Compounds?

Izixhobo zekhebula ezingenayo i-halogen (LSZH) eziphantsi zibaluleke kakhulu kukhuseleko lwekhebula lanamhlanje kunye nokuzinza. Sekunjalo, ukufikelela ekuqhubekekeni kakuhle kweenkqubo kusengumngeni. Ukusetyenziswa kakhulu kwezizalisi ezithintela ilangatye—ezifana ne-aluminium hydroxide (ATH) kunye ne-magnesium hydroxide (MDH)—kudla ngokubangela ukungakwazi ukuhamba kakuhle, i-torque ephezulu, ukugqitywa komphezulu orhabaxa, kunye nokwakheka koxinzelelo ngexesha lokukhupha.

Kutheni kunzima ukucubungula iiLSZH Cable Compounds?

Iimpawu zentambo kunye neentambo ezithintela umlilo ezingenamsi uphantsi ze-halogen kukuba zonke izinto azina-halogen, kwaye umsi omncinci kakhulu uya kukhutshwa ngexesha lokutsha. Ukuze kufezekiswe ezi zinto zimbini ziphambili, kongezwa inani elikhulu lezinto ezithintela umlilo kwinkqubo yemveliso, nto leyo ekhokelela ngokuthe ngqo kuthotho lweengxaki zokucubungula.

Ezi zilandelayo ziimpawu eziqhelekileyo zokucubungula ii-cable compounds ezingenamsi uphantsi ze-halogen:

1. Ngenxa yobuninzi bezinto zokugcwalisa ezithintela ilangatye ezifana ne-aluminium hydroxide kunye ne-magnesium hydroxide ezongeziweyo, nto leyo ekhokelela ekubeni ukuhamba kwamanzi kube kubi, kunye nokuveliswa kobushushu obungqubanayo ngexesha lokucubungula kukhokelela ekunyukeni kobushushu, nto leyo ekhokelela ekuwohlokeni kwe-aluminium hydroxide kunye ne-magnesium hydroxide.

2. Ukusebenza kakuhle kokukhupha amanzi, kunye nesantya esiphezulu sokukhupha amanzi, amandla okukhupha amanzi akatshintshi.

3. Ngenxa yokungahambi kakuhle kwee-polyolefins kunye nezithinteli zomlilo kunye nezinye izizalisi, nto leyo ebangela ukuba zingasasazeki kakuhle ngexesha lokucubungula kunye nokuncipha kweempawu zoomatshini.

4. Ukusasazeka okungalinganiyo kwezinto ezithintela ilangatye ezingaphiliyo kwinkqubo kukhokelela kumphezulu orhabaxa kunye nokungabikho kokukhanya ngexesha lokuphuma.

5. I-polarity yesakhiwo se-flame retardant kunye nezinye izinto ezizalisa i-fillers ibangela ukuba i-melt inamathele kwi-die head, ilibazise ukususwa kwezinto, okanye ukuna kwee-molecules ezisezantsi kwi-formulation, nto leyo ebangela ukuba izinto ziqokeleleke emlonyeni we-die, ngaloo ndlela ichaphazela umgangatho we-cable.

Ungayisombulula njani intambo ye-LSZH le micimbi yenkqubo kunye nomgangatho womphezulu?

Ukuze soyise ezi ngxaki,iteknoloji ye-silicone masterbatchiye yaba sisisombululo esithembekileyo kwiifomyula ze-LSZH compound, iphucula ukusebenza kakuhle kokucubungula kunye nokusebenza komphezulu ngaphandle kokuphazamisa iipropati zoomatshini okanye zombane.

Kutheni kunjaloi-silicone masterbatch isisombululo esisebenzayoukuphucula ukucubungula kunye nokusebenza komphezulu weekhompawundi zekhebula ze-LSZH?

I-silicone masterbatch luhlobo lweisongezo sokusebenza esisebenzayokunye nee-thermoplastics ezahlukeneyo njengezithwali kunye ne-polysiloxane njengeendawo ezisebenzayo. Kwelinye icala, i-masterbatch esekwe kwi-silicone inokuphucula amandla okuhamba kwenkqubo ye-thermoplastic ngexesha lemeko enyibilikisiweyo, iphucule ukusasazeka kwezizalisi, inciphise ukusetyenziswa kwamandla kwe-extrusion kunye ne-injection molding, kwaye iphucule ukusebenza kakuhle kwemveliso; Kwelinye icala, olu ncedo lokucubungula olusekwe kwi-Silicone lunokuphucula ukuguda komphezulu weemveliso zeplastiki zokugqibela, lunciphise i-coefficient yokungqubana komphezulu kwaye luphucule ukuguguleka nokukrweleka. Ukongeza, njengoncedo lokucubungula kwishishini le-thermoplastic, i-silicone masterbatch inokufezekisa isiphumo sokuguqula esicacileyo ngesixa esincinci (< 5%), ngaphandle kokuqwalasela kakhulu impendulo yayo nezinto ze-matrix.

I-Chengdu Silike Technology Co., Ltd. ngumvelisi ohamba phambili waseTshayina ogxile kwiizongezo ezisekelwe kwi-siliconekwimizi-mveliso yeplastiki nerabha. Ngaphezulu kweminyaka engama-20 yophando oluzinikeleyo olugxile ekudityanisweni kwe-silicone kunye nee-polymers, iSilike izibonakalise njengeqabane elitsha nelithembekileyo lezisombululo zezongezo ezisebenzayo.

Ukunceda abavelisi ukuba bakwazi ukumelana nemingeni yemveliso enxulumene neentambo ze-LSZH, iSilike iphuhlise ipotifoliyo ebanzi yeizongezo zeplastiki zesiliconeYenzelwe ngokukodwa ukuphucula ukucutshungulwa kweekhompawundi zekhebula. Iimveliso eziphawulekayo, ezifana neSilicone Masterbatch LYSI-401 kunye neSilicone Masterbatch LYSI-502C, zibonelela ngezisombululo ezisebenzayo ezijolise ekuphuculeni ukucutshungulwa kunye nomgangatho womphezulu, ngaloo ndlela zinegalelo ekusebenzeni okuphezulu kwiifowuni nakwiinkqubo zekhebula.

Iingenelo Zokusebenza: Iziphumo Zovavanyo Oluqhelekileyo lweSilicone Masterbatch kwiLSZH Cable Compounds

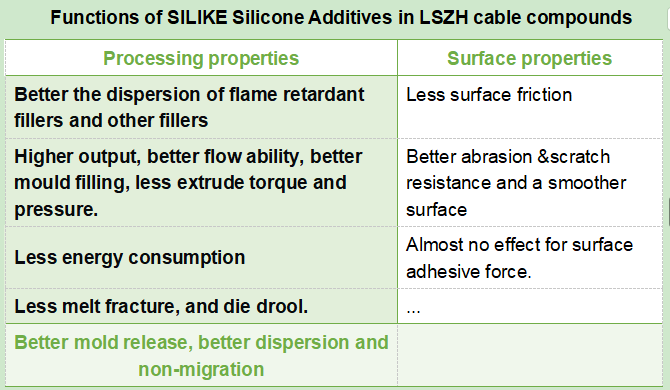

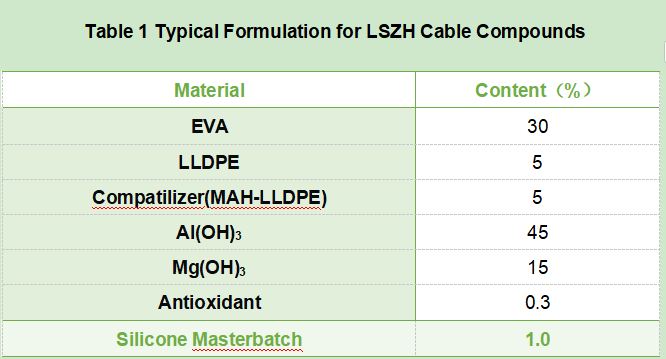

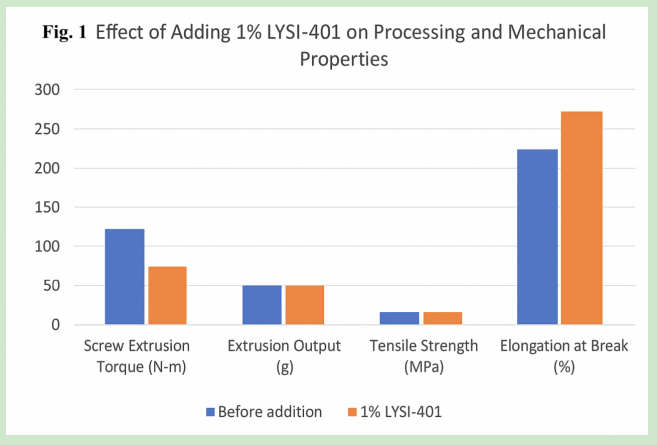

Ukongeza i-SILIKEI-Silicone Masterbatch (iSiloxane Masterbatch) uthotho lwe-LYSIKwinkqubo yokuzalisa ethintela ilangatye ephezulu, izixhobo zekhebula ezingenamsi ophantsi ze-halogen zinokuphucula ukugeleza kokucubungula, zinciphise i-torque, kwaye ziphucule ukusebenza kakuhle kwemveliso. Umfanekiso 1 ubonisa uthelekiso lovavanyo lokusebenza kwekhebula emva kokongeza i-1%I-LYSI-401 i-masterbatch ye-siliconekwifomula yenkampani yethu elinganisiweyo ngokubanzi engenamsi ophantsi we-halogen (Itheyibhile 1). Kuyabonakala ukuba ukusebenza okufanelekileyo kuphuculwe kakhulu.

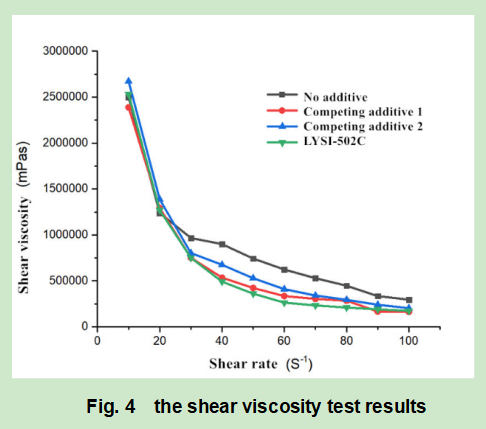

Umfanekiso 2, Umfanekiso 3, kunye noMfanekiso 4 ubonisa uvavanyo lwe-torque rheometer ye-siloxane High ContentI-silicone masterbatch LYSI-502Cyongezwe kwifomula eqhelekileyo engenamsi ophantsi we-halogen kunye nokuthelekiswa ne-torque, uxinzelelo, kunye ne-shear viscosity yeemveliso zangaphandle ezikhuphisanayo. Kuyabonakala ukuba i-LYSI-502C inomsebenzi ogqwesileyo wokuthambisa.

Umfanekiso 5 ubonelela ngokulinganisa okuxabisekileyo kwezinto eziqokelelweyo kwi-cable extrusion die emva kokongezwa kwe-silicone masterbatch. Iziphumo zibonisa ukuba ukufakwa kwe-silicone masterbatch eqhelekileyo kunciphisa kakhulu ukwakheka kwe-die. Ngaphezu koko, i-SILIKE'si-masterbatch ye-silicone enobunzima obuphezuluibonisa isiphumo esicacileyo ngakumbi ekunciphiseni ukwakheka kwe-die, nto leyo ebonisa ukuba inamandla okuphucula ukusebenza kakuhle kokucubungula.

Isishwankathelo:I-siloxane ekhoyo kwi-standardii-masterbatches ze-siliconeayiyo-polar, nto leyo enokubangela imingeni xa kujongwa iiparameter ezahlukeneyo zokunyibilika kweepolymers ezininzi ze-carbon chain. Xa ukongezwa kugqithisile, kunokukhokelela kwimiba efana nokutyibilika kwezikrufu, ukuthambisa okugqithisileyo, ukwahlukana komphezulu wemveliso, ukusebenza okubuthathaka kokubopha, kunye nokusasazwa okungalinganiyo ngaphakathi kwe-substrate.

Ukujongana nale mingeni, i-SILIKE iphuhlise uthotho lweenkquboizongezo ze-silicone ezinobunzima obukhulu kakhulueziguqulwa ngamaqela akhethekileyo asebenzayo.izongezo zokucubungula i-polymer ezisekwe kwi-siliconeZenzelwe ukuhlangabezana neemfuno ezithile zesicelo kwiinkqubo ezahlukeneyo ze-thermoplastic. Ngokusebenza njengee-anchors ngaphakathi kwe-substrate, ziphucula ukuhambelana, ziphucula ukusasazeka, kwaye zomeleza ukunamathela. Oku kuphumela ekuphuculweni okukhulu kokusebenza kwe-substrate iyonke. Kwiinkqubo ezingenamsi uphantsi, ezingenayo i-halogen, ezi zongezo zintsha zithintela ukutyibilika kwezikrufu kwaye zinciphisa kakhulu ukuqokelelana kwezinto ezifileyo.

Ngaba ukhangela iisongezo sokucubungula ipolymerukuphucula inkqubo yakho yokwenziwa kweentambo ze-LSZH?

Hlola indlela izisombululo ze-masterbatch ezisekelwe kwi-silicone ze-SILIKE, kuquka i-LYSI-401 ye-silicone kunye ne-siloxane masterbatch LYSI-502C, ezinokukunceda ngayo ekuphuculeni imveliso, ukunciphisa ukugcinwa kweedayi, kunye nokufikelela kumgangatho ophezulu wekhebula. Siyakumema ukuba unxibelelane nathi ukuze ufumane ulwazi oluthe kratya kwaye ucele isampulu.

Iwebhusayithi: www.siliketech.com

Email: amy.wang@silike.cn

Ixesha lokuthumela: Okthobha-10-2025