Yintoni iPolyolefin Blown Film Extrusion?

I-polyolefin blowed film extrusion isetyenziswa kakhulu ukuvelisa iifilimu zokupakisha ukutya, iimpahla zabathengi, ii-industrial closures, iifilimu zezolimo, kunye neephakheji zokukhusela.

Ukuveliswa kweefilimu ezitshatyalalisiweyo zanamhlanje kufuna iifilimu ezinciphileyo, amazinga aphezulu okukhupha, umgangatho womphezulu ogudileyo, kunye nokukhutshwa okuzinzileyo kwexesha elide.

Ukufezekisa ezi njongo, iiprosesa zihlala zisebenzisa i-LLDPE, i-MLLDPE, i-LDPE, kunye ne-metallocene polyolefins, ezibeka imfuneko ephezulu ekusebenzeni kakuhle kwe-extrusion.

Imingeni eqhelekileyo yokucubungula kwi-Blown Film Extrusion

Njengoko isantya semveliso sisanda kwaye ubukhulu befilimu buncipha, abavelisi befilimu ephuphumayo bahlala bedibana nezi:

× Ukuqhekeka kwesikhumba (i-sharkskin) okunyibilikayo ngesantya esiphezulu

×Ukuhamba kakubi kokunyibilika kunye nokuziphatha okungazinzanga kwamaqamza

×Ukuqokelelana okukhulu kweentsimbi kunye nokucoca rhoqo

× Uxinzelelo oluphezulu lwe-torque kunye ne-extrusion

×Ukuthembela kakhulu kwiindlela zokuncedisa ukucubungula i-PPA ene-fluorinated

Ezi ngxaki zithintela ukusebenza kakuhle kwemveliso, ukubonakala komphezulu, kunye nokuzinza kokusebenza.

Kutheni ii-PPA ezifakwe i-Fluorinated zithathelwa indawo kwizicelo zefilimu ezifakwe i-Blown?

Izixhobo zokulungisa i-polymer ene-fluorine bezisoloko zisetyenziselwa ukuphucula ukuhamba kwe-melt kunye nokuthintela ukwaphuka kwe-melt.

Nangona kunjalo, uxinzelelo olukhulayo lolawulo lwe-PFAS, ngakumbi kwiipakethe kunye nezicelo zokunxibelelana nokutya, luqhubela phambili eli shishini kwiindlela ezingena-fluorine.

Abavelisi beefilimu ezidumileyo kufuneka balinganisele ngakumbi:

•Ukusebenza kwe-extrusion ekhawulezayo

•Ukuthobela imithetho kunye nozinzo

•Ukuthembeka kwefomyula yexesha elide

Isisombululo se-PPA sasimahla se-SILIKE PFAS se-Blown Film Extrusion

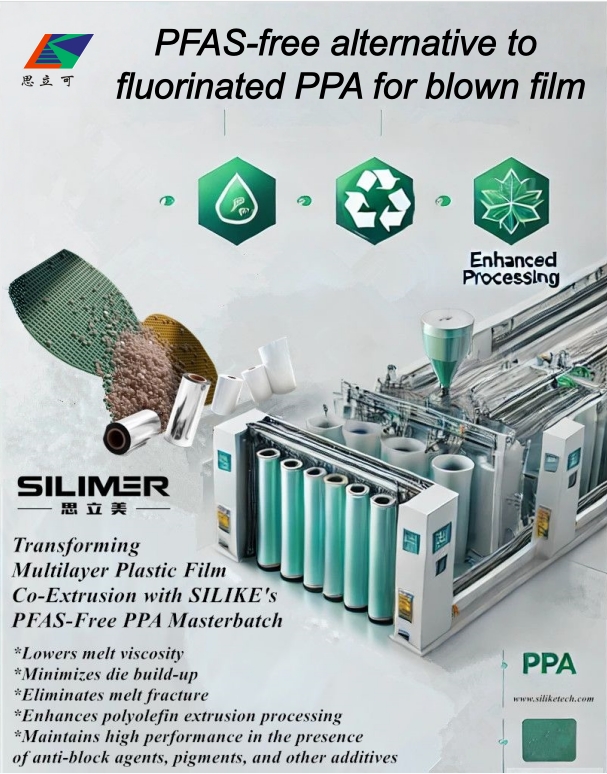

SILIKE SILIMER PFAS-I-PPA Masterbatch yasimahlayiuncedo lokucubungula olungenafluorineyenzelwe ukukhupha i-polyolefin, kuquka ukusetyenziswa kwefilimu evuthuziweyo.

Ngomgangatho ophantsi wokongeza, i-SILIMER inceda abaprosesa ukuba bafumane i-extrusion ezinzileyo nephumayo ephezulu ngaphandle kwe-PFAS.

Iingenelo eziphambili zezixhobo zokucubungula ezingenayo i-SILIKE PFAS kwi-Blown Film Extrusion:

√Ukuhamba okuphuculweyo kokunyibilika kunye nokuzinza kokucubungula

√Ukususa ngempumelelo ukwaphuka okunyibilikileyo (isikhumba sooshaka)

√Ukuncipha kokwakheka kweedayi kunye nokucoca ixesha elide

√I-torque ephantsi yokukhupha kunye noxinzelelo

√Umgangatho wefilimu ogudileyo nofanayo

Izicelo eziqhelekileyo

•Iifilimu ezivuthelweyo zePolyolefin (PE / LLDPE / mLLDPE)

•Iifilimu zokupakisha ezilinganisiweyo

•Ukutya kunye nokupakishwa kwemizi-mveliso

•Iifilimu zezolimo nezokukhusela

Kutheni ukhetha i-SILIKE njengoMboneleli we-PPA ongenazo i-PFAS?

With over 20 years of expertise in silicone-modified polymer additives, SILIKE offers PFAS-free processing solutions customized to address the challenges of modern blown film extrusion. If you are seeking an alternative to fluorinated PPA, contact amy.wang@silike.cn to obtain our Blown film processing aid – Fluorine-free processing aid. Or,ndwendwela iwebhusayithi:www.siliketech.com to funda ngakumbi malungaI-SILIMER PFAS kunye nezinye izisombululo ezingena-fluorine!

Imibuzo Ebuzwa Rhoqo Ngokuphathelele Ukucubungula Ifilimu Eqhumayo (i-PPA EngenaPFAS)

Umbuzo:Ingasuswa njani i-melted fracture xa kuphuma ifilimu eqhumayo?

Impendulo:

Ukuqhekeka kwe-melt kwi-extrusion yefilimu eqhumayo kubangelwa kukuxinana okuphezulu kodonga lwe-die, ingakumbi xa i-output rates iphezulu.

Ukusebenzisauncedo lokucubungula i-polymer tIsigqoko sinciphisa ukungqubana okunyibilikayo sisisombululo esisebenzayo.

Iiprosesa ezininzi ngoku zisebenzisa ii-PPA ezingenayo i-PFAS, ezifana ne-SILIKE SILIMERSILIKE SILIMER iPPA engenaFluorine,ukuphelisa ukwaphuka kokunyibilika ngelixa kugcinwa ukuthotyelwa kwemithetho.

UmbuzoKutheni izixhobo zokucubungula ziyimfuneko kwiifilimu zanamhlanje ezitshatyalalisiweyo?

Impendulo:

Ukuveliswa kwefilimu ephucukileyo yanamhlanje kufuna iifilimu ezincinci kunye nemveliso ephezulu, kusetyenziswa rhoqo i-mLLDPE kunye ne-metallocene polyolefins.

Ezi zinto ziphucula amandla kodwa zinciphisa uzinzo ekucutshungulweni, nto leyo eyenza izixhobo zokucubungula zibe zibalulekile ekukhutshweni rhoqo.

Impendulo:

Ii-PPA ezingenayo i-PFAS ezisekelwe kwitekhnoloji ye-polymer eguqulwe yi-silicone zisetyenziswa kakhulu njengezinye iindlela.

I-SILIKE SILIMER PFAS-Free PPA yenzelwe ukukhupha ifilimu eqhushumbiswe yi-polyolefin kwaye inika ukusebenza okuzinzileyo, okunemveliso ephezulu.

Umbuzo: Do Ii-PPA ezingenayo i-PFASichaphazela iipropati zoomatshini zefilimu eqhushumbisiweyo?

Impendulo:

Hayi. Ii-PPA ezingenayo i-PFAS ezenziwe kakuhle azichaphazeli kakubi amandla efilimu, ukusebenza kokutywina, okanye inkangeleko.

Ixesha leposi: Disemba-31-2025