I-Color Masterbatch luhlobo olutsha lwe-arhente ekhethekileyo yokufaka imibala kwizinto ze-polymer, eyaziwa ngokuba kukulungiselela i-pigment. Iqulathe izinto ezintathu ezisisiseko: i-pigment okanye idayi, i-carrier kunye nezongezo, kwaye yi-aggregate efunyenwe ngokuncamathisela ngokulinganayo ubungakanani obungaqhelekanga be-pigment okanye idayi kwi-resin. Izixhobo zokucubungula ziyafuneka ukuqinisekisa ukuba ubungakanani obukhulu be-pigment bunokusasazwa ngokulinganayo, ukuthintela ukuhlangana, kunye nokuphepha iingxaki ezinje ngokuqhekeka kokunyibilika kunye nokunciphisa ukwakheka kwe-die ngexesha lokucubungula.

Kukho izongezo ezininzi ezithengiswayo ezinokuthi zisetyenziswe kwi-color masterbatch, loluphi uhlobo lwezongezo olunokusombulula ngcono ezi ngxaki zingasentla?

I-SILIMERuthothoi-silicone hyperdispersant, Khuthaza ukusasazwa kweempuphu zombala ngendlela efanelekileyo nefanayo

Ingxaki 1: Iimpawu zokuhamba kwe-Masterbatch extrusion yombala, umphezulu ombi wemveliso kwinkqubo yokucubungula i-masterbatch.

Ingxaki 2: I-masterbatch ejikelezayo kulula ukuyiphula, ayisebenzi kakuhle, kwaye ixabiso lokucoca alilungile.

Uhlalutyo lwesizathu: Isizathu esiphambili kukuba ubungakanani besuntswana lomgubo wombala bukhulu kakhulu okanye umbala womgubo awusasazeki ngokulinganayo kwaye uhlangana kwicala elithile ngexesha lokucubungula.

Isisombululo: I-SILIKE SILIMER series silicone hyperdispersantluhlobo lwemveliso ye-polysiloxane ye-copolymer eguquliweyo, enokuphucula ukuhambelana phakathi komgubo wombala kunye ne-resin substrate, ikhuthaze ukusasazeka okusebenzayo nokulinganayo komgubo wombala kwaye iwugcine uzinzile, nokuba yi-chromaticity, iphucule amandla ombala we-pigment, iphucule ukugeleza kwenkqubo, iphucule ukusebenza kokucubungula, kwaye okwangoku, inokunciphisa i-coefficient yokungqubana komphezulu ngokusebenzisa iimpawu zamandla aphantsi okujikeleza kwe-silicon chain, ukuze iphucule ukuguda komphezulu weemveliso. Kwaye inokuqinisekisa ukuveliswa okugudileyo kokujikeleza kwe-extrusion.

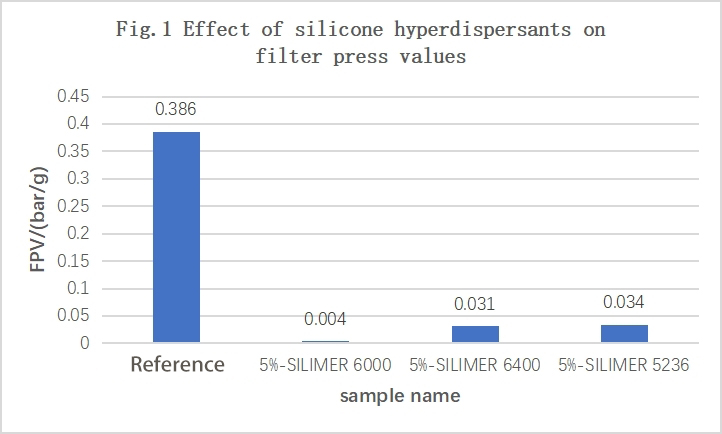

Njengoko kubonisiwe kuMfanekiso 1, phantsi kobushushu bovavanyo: 235℃; isampuli iyonke: 1000g; ubunzima bepigment: 80g; ukongezwa kwe-masterbatch: 20%; i-substrate PP: 80%; iinkcukacha zesihluzo: iimeko zovavanyo lwe-mesh ezili-1000, kunokubonwa ukuba emva kokongezwa kwe-SILIKE silicone hyperdispersantSILIMER6000, SILIMER6400, SILIMER5236kwi-masterbatch, ixabiso lokucoca uxinzelelo lincitshisiwe kakhulu, nto leyo ebonisa ukubaI-SILIKE silicone hyperdispersantiphucula ngokufanelekileyo indlela i-agglomeration yepowder edibeneyo, kwaye iphucula ngakumbi indlela i-powder esasazeka ngayo. I-dispersant ingasetyenziselwa ukuphucula indlela i-powder esasazeka ngayo.

Uncedo lweNkqubo yePolymer ye-SILIKE PFAS yasimahla, Susa ukwaphuka okunyibilikileyo kwaye wandise imijikelo yokucoca izixhobo

Ingxaki 3: I-color masterbatch extrusion outlet mold iqokelela izinto, kwaye umjikelo wokucoca izixhobo umfutshane.

Uhlalutyo lwesizathu: Ngenxa yokungahambi kakuhle komgubo wombala kunye nezinto ezisisiseko, inxalenye yomgubo wombala kulula ukuyidibanisa emva kokuxuba, kukho umahluko phakathi kokuguquguquka komgubo wombala kunye ne-resin kwaye i-viscosity yokunyibilika inkulu kwinkqubo yokukhupha, kwangaxeshanye, kukho isiphumo esixineneyo phakathi kwezixhobo zokukhupha isinyithi kunye nenkqubo ye-resin, ekhokelela kwizixhobo ezifileyo emzimbeni wegumbi kunye nokukhupha umlomo we-die, umgubo wombala kunye ne-thermoplastic resin ziyasuswa ngexesha lenkqubo yokukhupha okubangela ukuba izinto ziqokeleleke emlonyeni nase-die, kwaye indima phakathi kokunyibilika kwe-resin kunye nezixhobo zesinyithi kufuneka incitshiswe ukuze kuthintelwe imeko enjalo. Kubalulekile ukwenza buthathaka ukusebenzisana phakathi kokunyibilika kwe-resin kunye nezixhobo zesinyithi ukuze kuthintelwe le meko.

Ingxaki 4: Ukunyibilika kokuqhekeka ngexesha lokukhupha ngesantya esiphezulu, ukwahlulwa komgubo wombala kunye nokuna kwemvula.

Uhlalutyo lwesizathu: Njengoko izinga elibalulekileyo lokucheba lezinto ngokwazo lincinci xa inkqubo yomgubo wombala ikhutshwa ngesantya esiphezulu, kuya kubakho iingxaki ezinkulu zokuqhekeka kokunyibilika kunye nokwakheka kokufa xa ikhutshwa ngesantya esiphezulu, nto leyo eya kubangela ukwahlukana kunye nokuna kwempuphu yombala. I-Fluoropolymer yipolymer ene-viscosity ephezulu kwinkqubo yomgubo wombala kwinkqubo yokufuduka ngaphandle ayilunganga, isiphumo sokuphucula siqhelekile.

Isisombululo: Izixhobo zokucubungula i-PPA ezingenayo i-SILIKE PFASyimveliso ye-polysiloxane masterbatch eguqulwe ngokwendalo edibanisa amacandelo e-polysiloxane chain kunye namaqela e-polar, idibanisa ukusebenza okuhle kakhulu kwazo zombini, kwaye iphucula isakhiwo ngaxeshanye. I-PPA engena-Fluorine isebenzisa amaqela ahlengahlengisiweyo anokudibana ngamandla nezikrufu zesinyithi ukuze athathe indawo yendima ye-fluorine kwi-PPA equlethe i-fluorine, aze asebenzise iimpawu zamandla aphantsi omphezulu we-silicone ukwenza ifilimu ye-silicone kumphezulu wezixhobo zesinyithi ukufezekisa isiphumo sokwahlulwa, okwandisa ngempumelelo umjikelo wokucoca wezixhobo ukuze kufinyezwe ixesha lokungasebenzi, kupheliswe ukwaphuka okunyibilikayo, kuncitshiswe ukwakheka kwe-die, kwaye kuphuculwe indima yomgangatho womphezulu. Ukongeza, ikwanazo neempawu zokhuseleko lokusingqongileyo olungeyo-PFAS, kuncitshiswe i-extrusion torque, kuphuculwe ukugeleza kokucubungula njalo njalo.

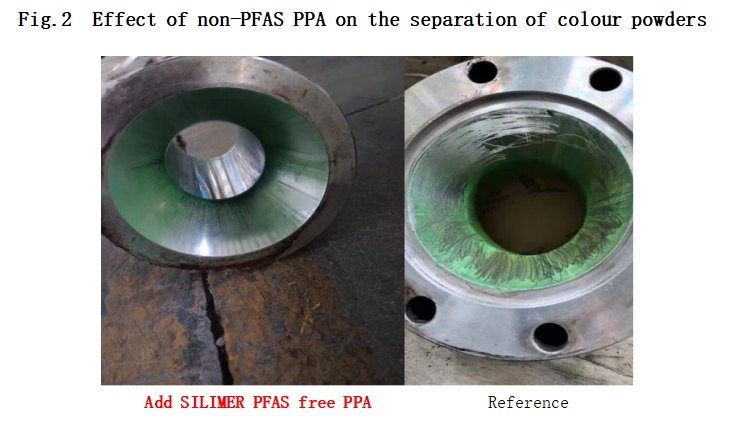

Njengoko kubonisiwe kuMfanekiso 2, emva kokuba umthengi esebenziseIzixhobo zoLungiso lwePolymer ezingenayo i-SILIKE PFAS, ngexesha elifanayo lokucubungula, umbala wepowder onamathela eludongeni lwangaphakathi lomatshini uphuculwe kakhulu.

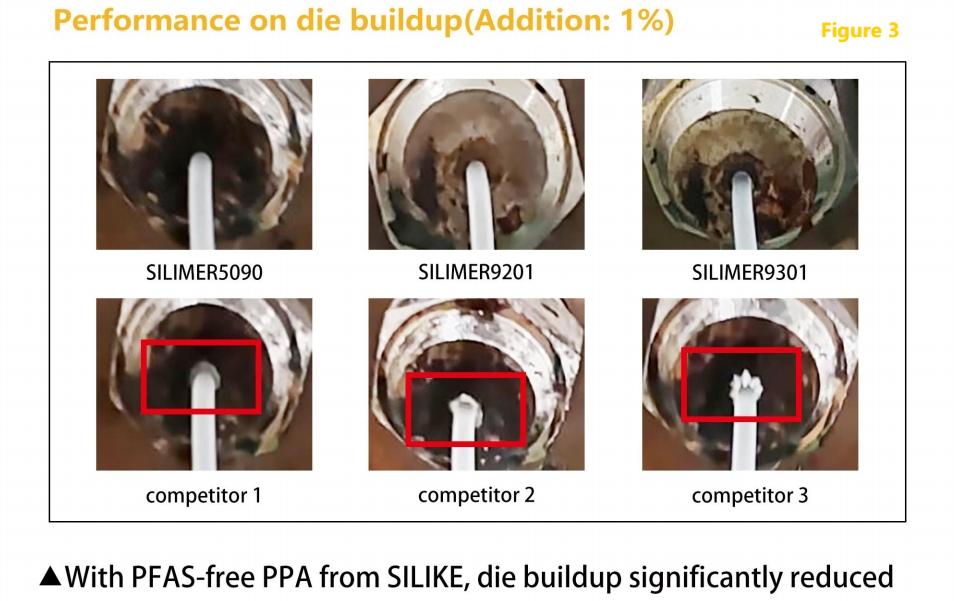

Njengoko kubonisiwe kuMfanekiso 3, imeko yokuphuma ngaphantsi kwemizuzu engama-30 kunye nomlinganiselo ofanayo wokongeza, ukuphuculwa kwe-SILIKE non-PFAS PPA kwi-die build-up kungcono kakhulu kunoko kwe-PPA ene-fluorinated.

Abavelisi beColor Masterbatch, ukuba uhlangabezana neengxaki okanye iingxaki ngexesha lokucubungula i-masterbatch, nceda unxibelelane nathi, i-SILIKE ingakunika izisombululo zokucubungula ezenzelwe wena.

I-Chengdu SILIKE Technology Co., Ltd, inkokheli yaseTshayinaIsongezo seSiliconeUmboneleli weplastiki eguquliweyo, unikezela ngezisombululo ezintsha zokuphucula ukusebenza kunye nokusebenza kwezixhobo zeplastiki. Wamkelekile ukuba unxibelelane nathi, i-SILIKE iza kukunika izisombululo ezisebenzayo zokucubungula iplastiki.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn.

iwebhusayithi:www.siliketech.comukuze ufunde okungakumbi.

Ixesha leposi: Oktobha-16-2024