Umgubo omhlophe ogqumayo kwingxowa yokupakisha ukutya kungenxa yokuba i-slip agent (i-oleic acid amide, i-erucic acid amide) esetyenziswa ngumvelisi wefilimu ngokwayo iyagquma, kwaye indlela esebenza ngayo i-amide slip agent yendabuko kukuba isithako esisebenzayo sifuduka siye kumphezulu wefilimu, senze umaleko omnye wokuthambisa wemolekyuli kwaye sinciphise i-friction coefficient yomphezulu wefilimu. Nangona kunjalo, ngenxa yobunzima obuncinci bemolekyuli ye-amide slip agent, kulula ukuyigquma okanye ukuyigquma, ngoko ke umgubo kulula ukuhlala kwi-composite roller ngexesha lenkqubo yokudibanisa ifilimu, kwaye umgubo kwi-raber roller uya kunamathela ngexesha lokucubungula ifilimu, okubangela ukuba umgubo omhlophe ocacileyo kwimveliso yokugqibela.

Ukusombulula ingxaki yokuna kwe-amide slip agents zemveli, i-SILIKE iphuhlise imveliso ye-co-polysiloxane eguquliweyo equlethe amaqela asebenzayo e-organic –Iarhente yokutyibilika engaqhakaziyo yothotho lwe-SILIMERyefilimu yeplastiki. Umgaqo osebenzayo wale mveliso kukuba amaqela asebenzayo akwityathanga elide lekhabhoni anokwenza ikhonkco elibonakalayo okanye leekhemikhali kunye ne-base resin, esebenza njenge-ankile yokufezekisa ukufuduka okulula ngaphandle kwemvula. Amacandelo etyathanga le-polysiloxane kumphezulu anika isiphumo sokutyibilika. Amanqaku acetyiswayo:SILIMER5064, I-SILIMER5064MB1,SILIMER5064MB2, SILIMER5065HB…

1.Iinzuzo kunyeI-SILIMER Series Non-Precipitation Slip Agent Masterbatch

- Iza nokusebenza okuhlala ixesha elide kokutyibilika ngokuhamba kwexesha naphantsi kweemeko zobushushu obuphezulu

- Nika i-coefficient ezinzileyo nephantsi yokungqubana, i-anti-blocking elungileyo, kunye nobuthambile obungcono bomphezulu wemveliso yokugqibela.

- Ayichaphazeli ukuprinta, ukuvala ubushushu, i-composite, i-transparency, okanye i-haze

- Iphelisa iingxaki zepowder, ikhuselekile kwaye ayinavumba

- Isetyenziswa kakhulu kwiifilimu zeBOPP/CPP/PE/PP……

2.Idatha ethile yovavanyo lokusebenza efanelekileyo

- Ukunciphisa ngempumelelo i-frictional coefficient, akuchaphazeliinkungukunye nokudluliselwa

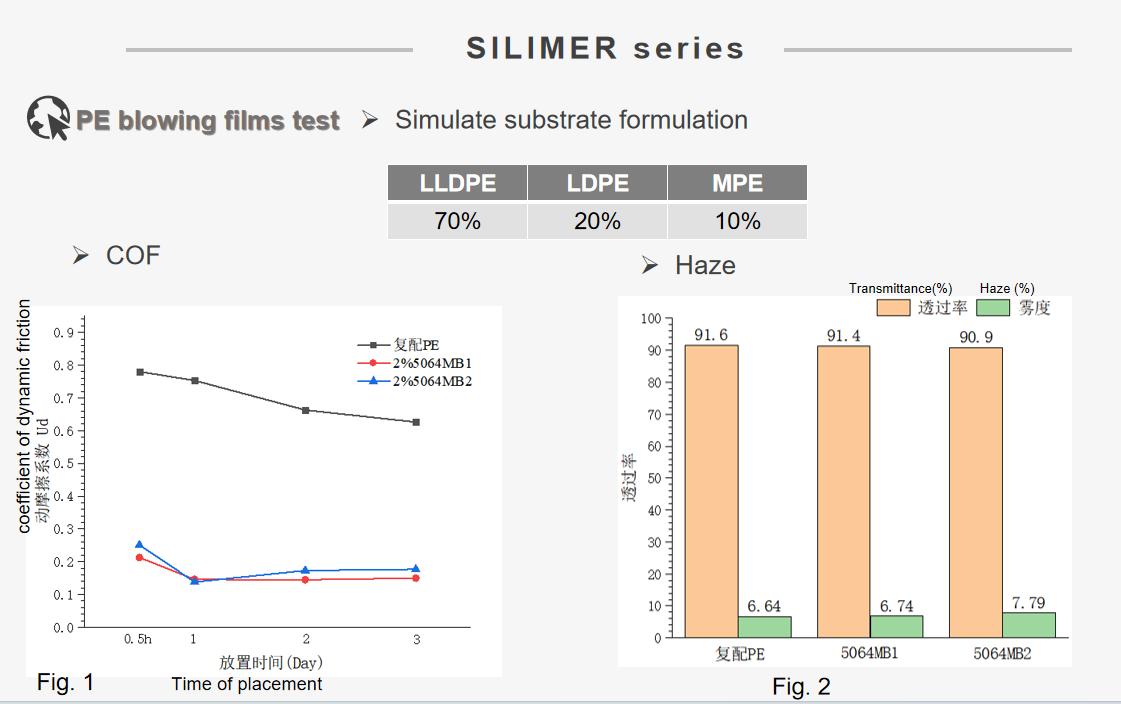

Ifomula yesiseko esilingisiweyo: 70%LLDPE, 20%LDPE, 10% metallocene PE

Njengoko kubonisiwe kuMfanekiso 1, i-coefficient yokungqubana kwefilimu emva kokongeza i-2%I-SILIMER 5064MB1kunye ne-2%I-SILIMER 5064MB2incitshiswe kakhulu xa ithelekiswa ne-composite PE. Ngaphezu koko, kwaye njengoko kubonisiwe kuMfanekiso 2, ukongezwa kweI-SILIMER 5064MB1kwayeI-SILIMER 5064MB2ayichaphazelanga inkungu kunye nokudluliselwa kwefilimu.

- I-coefficient yokungqubana izinzile

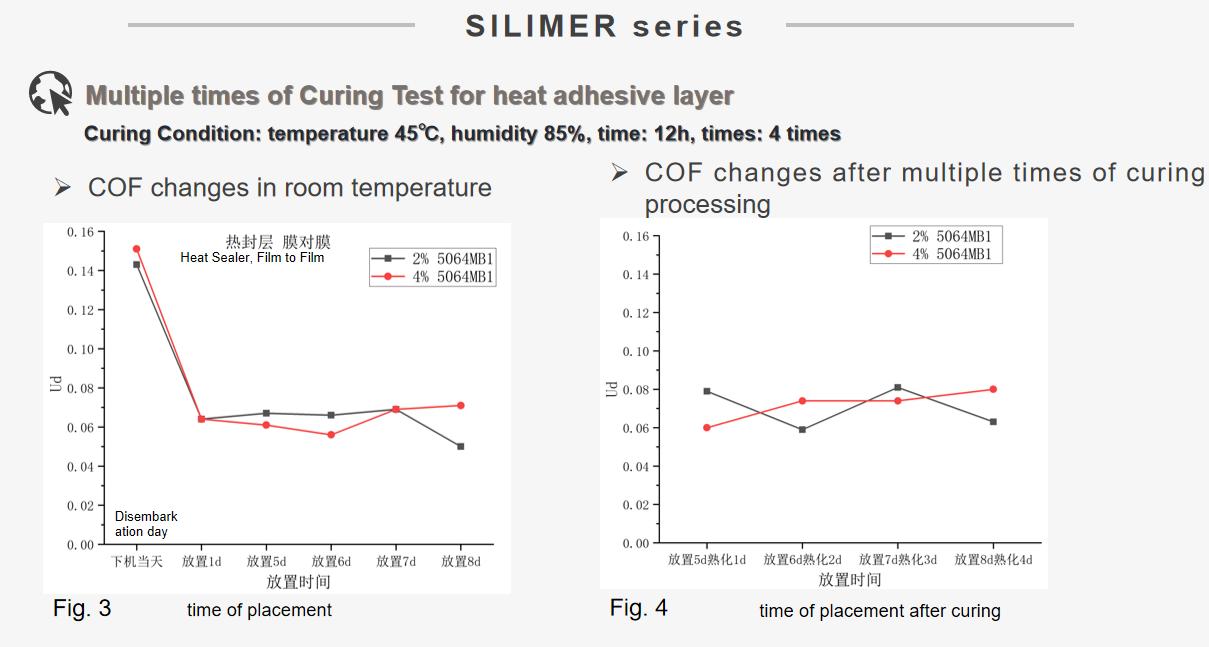

Iimeko zokuphilisa: ubushushu obuyi-45℃, ukufuma okungu-85%, ixesha leeyure ezili-12, amaxesha ama-4

Njengoko kubonisiwe kuMfanekiso 3 kunye noMfanekiso 4, kunokubonwa ukuba i-coefficient yokungqubana kwefilimu emva kokongeza i-2%I-SILIMER 5064MB1kunye ne-4%I-SILIMER 5064MB1ihlala ikwixabiso elizinzileyo emva kokunyanga izihlandlo ezininzi.

- Umphezulu wefilimu awugungqi kwaye awuchaphazeli umgangatho wezixhobo kunye nemveliso yokugqibela

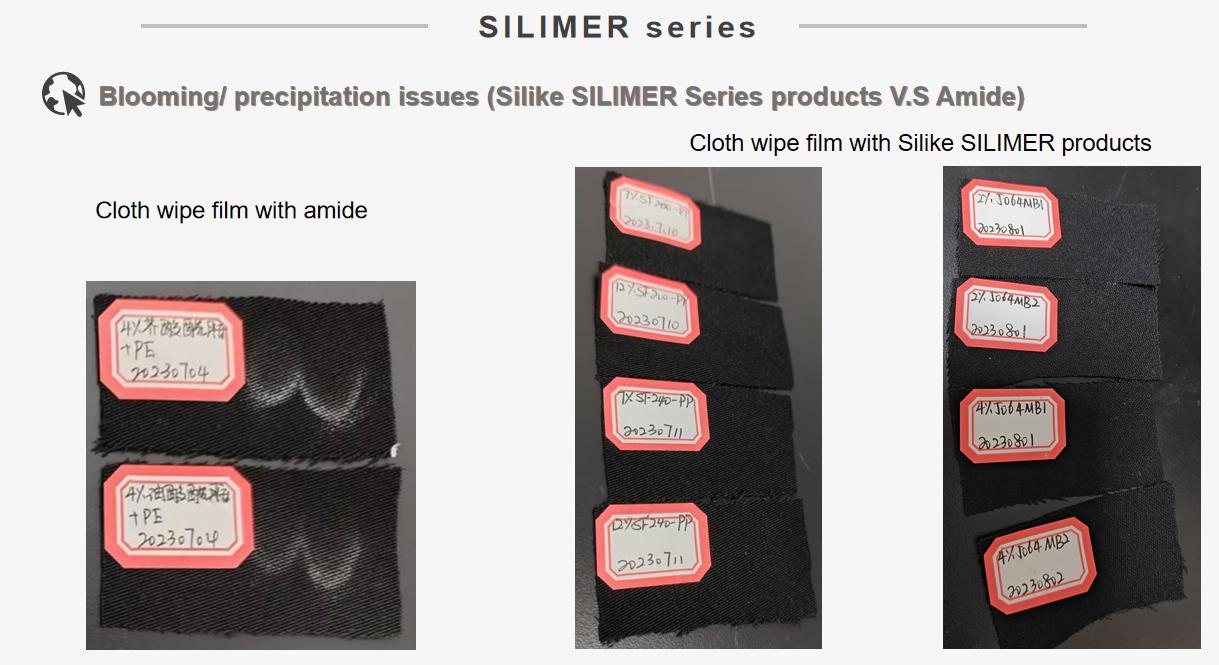

Njengoko kubonisiwe kumfanekiso ongezantsi, sebenzisa ilaphu elimnyama ukusula umphezulu wefilimu nge-amide kunyeImveliso ye-SILIMERKuyabonakala ukuba xa kuthelekiswa nokusetyenziswa kwezithako ze-amide, uthotho lwe-SILIMER alunawo umgubo obangela ukudumba.

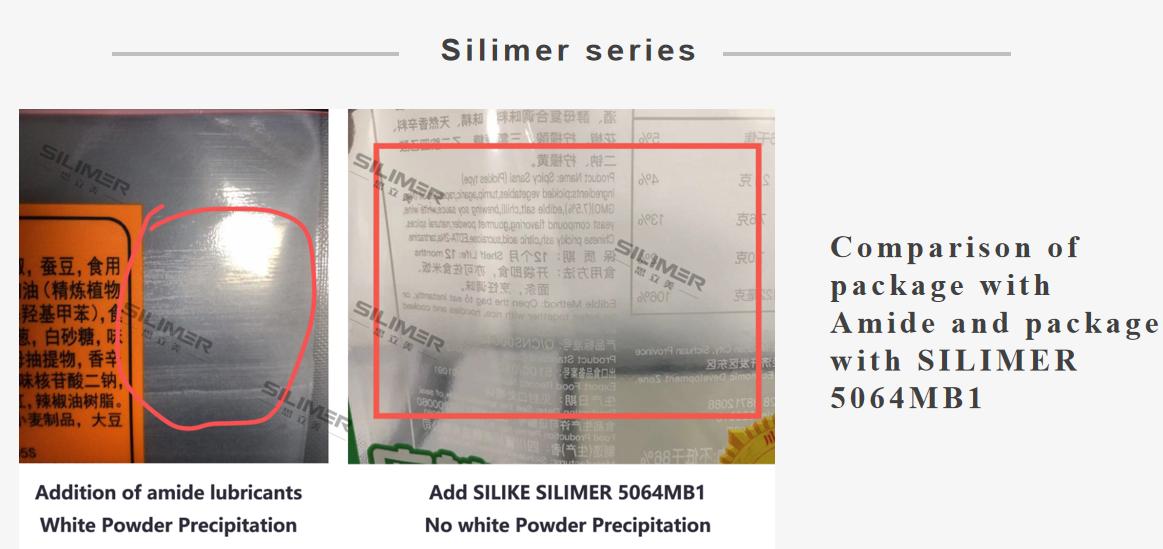

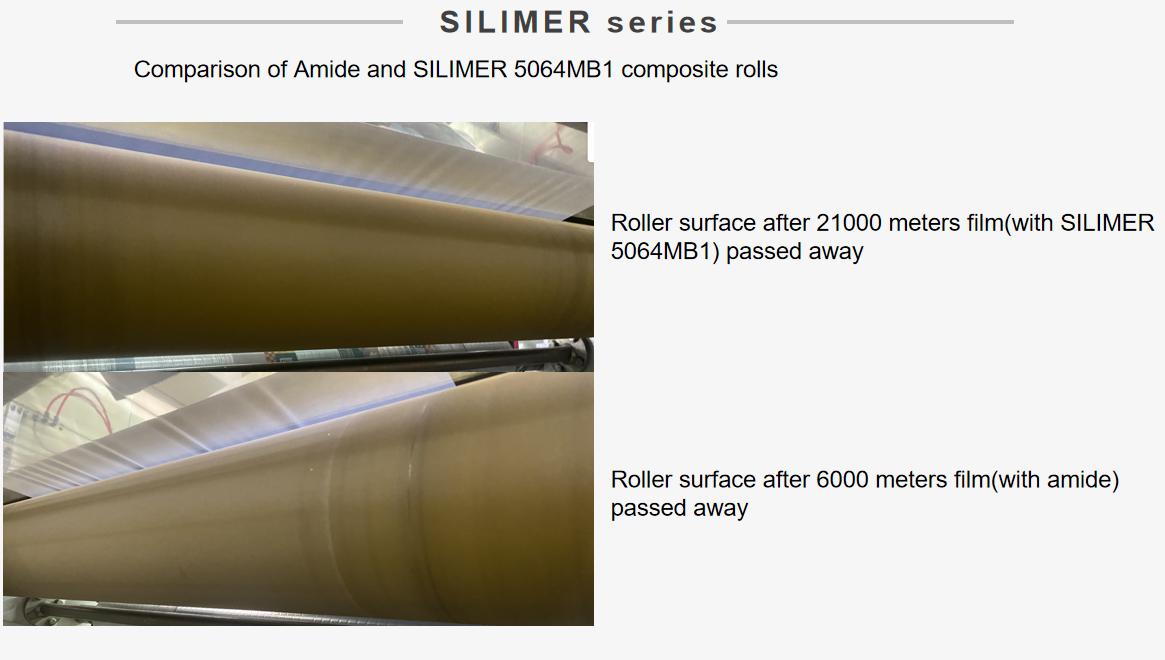

- Sombulula ingxaki yomgubo omhlophe kwi-composite roller kunye nebhegi yokugqibela yemveliso

Njengoko kubonisiwe kumfanekiso ongezantsi, emva kokuba i-composite roller idlule kwiimitha ezingama-6000 zefilimu ene-erucic acid amide, kukho ukuqokelelwa okucacileyo komgubo omhlophe, kwaye kukwakho nomgubo omhlophe ocacileyo kwibhegi yokugqibela yemveliso; Nangona kunjalo, isetyenziswa kunyeUthotho lwe-SILIMERSinokubona xa i-composite roller idlule kwiimitha ezingama-21000, kwaye ibhegi yokugqibela yemveliso yayicocekile kwaye intsha.

3. Amandla kaI-SILIKESILIMERuthothoisiliphu esisisigxina esingafudukiyoIsongezelelo sokuPakisha okuGuquguqukayo.

Guqula ukhuseleko lwakho lokupakishwa kokutya! Udiniwe yiMpuphu emhlophe enokuNyuka kwiingxowa zakho zokupakishwa ezidityanisiweyo okanye kwezinye iifilimu? Ulungele utshintsho?Uthotho lwe-SILIKE SILIMERIsithako esisisigxina esingafudukiyo sokongeza kwiPakethe eguquguqukayo,iarhente yokutyibilika engadubuliyo, i-masterbatch ye-arhente yokutyibiliza engekho phantsi kwemvula yefilimu yeplastiki, isusa iingxaki zepowder, iqinisekisa amava okupakisha angenasiphako kwaye acocekileyo. Qhagamshelana nathi ngoku! Masitshintshe amava akho okupakisha kunye!

Silapha ukuze senze izisombululo ezenzelwe wena!I-SILIKE SILIMER series non-precipitation slip agent masterbatchifanelekile kwiintlobo ngeentlobo zeplastiki, ingaphelelanga kwiifilimu zokupakisha (iifilimu zeBOPP, CPP, BOPET, EVA, TPU, LDPE, kunye neLLDPE.) ikwabonelela ngezisombululo zokutyibilika ezizinzileyo nezihlala zihleli zamaphepha kunye nezinye iimveliso zepolymer apho kufuneka ukutyibilika kunye neempawu zomphezulu eziphuculweyo.

Ixesha leposi: Jan-19-2024