Ulwazi lweShishini malunga nokuphucula ukusebenza kweNylon kwizicelo ze-High-Wear

Kwimeko ehlala itshintsha yeplastiki yobunjineli, izinto ze-nylon ezingagugiyo ziyaqhubeka nokudlala indima ebalulekileyo kumashishini amaninzi. Ukusuka kwizinto zeemoto ukuya koomatshini bemizi-mveliso, imfuno yezisombululo ze-nylon ezihlala ixesha elide nezingenazingxabano iqhubele phambili ubuchule obubalulekileyo kwisayensi yezinto eziphathekayo.

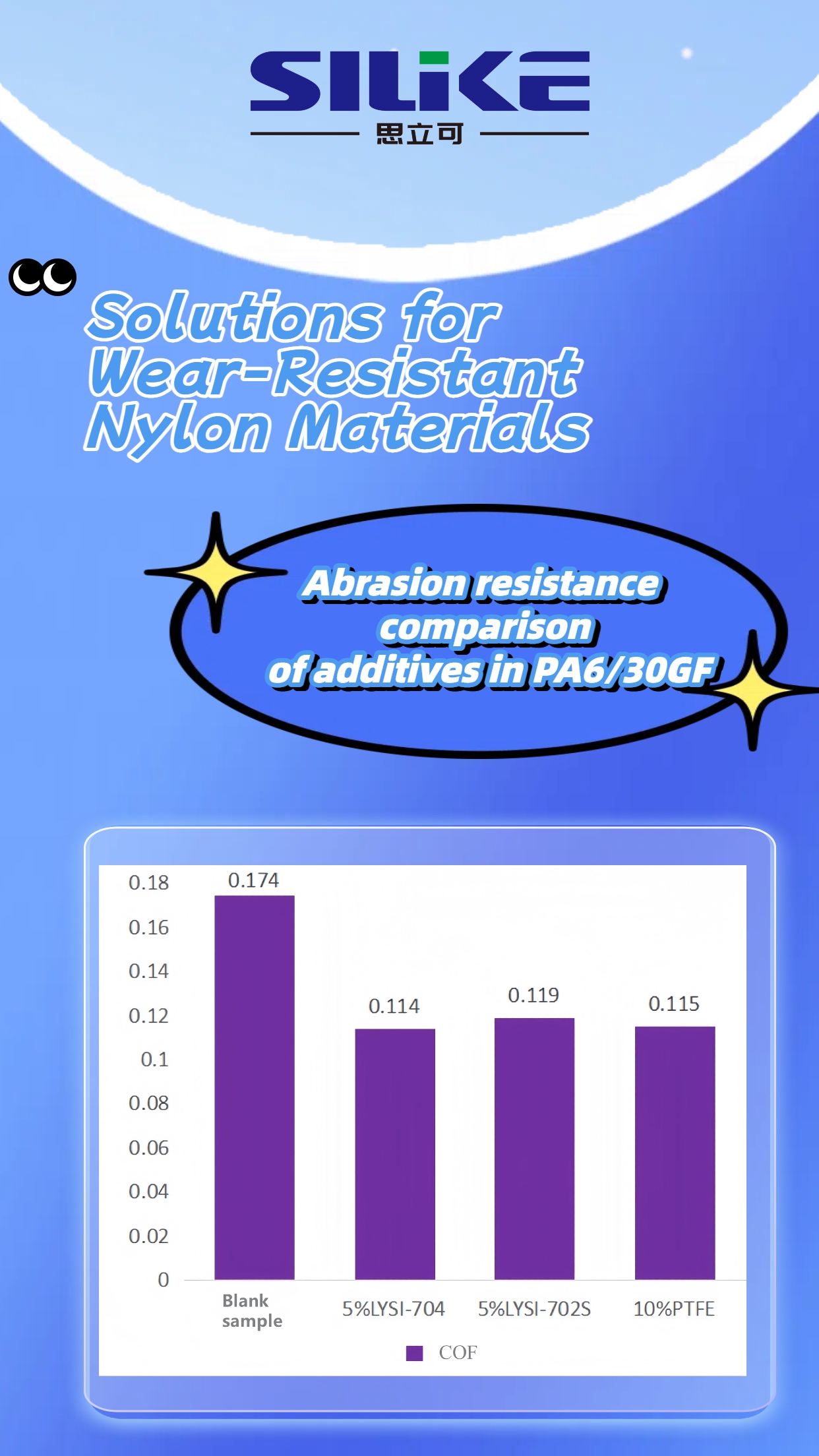

YemveliIzisombululoUkumelana nokunxitywa kweNylon

Uluntu lobunjineli luphuhlise iindlela ezininzi ezisemgangathweni zokuphucula ukumelana nokuguguleka kwe-PA6 kunye ne-PA66, iintlobo ze-nylon ezisetyenziswa kakhulu kwizicelo zoshishino.

1. Ukuqinisa iGlasi yeFiber:I-nylon eqinisiweyo yefayibha yeglasi (GF/PA6, GF/PA66) yenziwa ngokudibanisa iifayibha zeglasi zibe yi-matrix ye-nylon, nto leyo eyenza i-composite esebenza kakhulu ephucula kakhulu iipropati zoomatshini. Iifayibha zenza inethiwekhi ye-3D eqinisayo, yonyusa amandla okuxinana (ukuya kuthi ga kwi-4×), ukuqina (3–5× i-flexural modulus ephezulu), kunye nokumelana nobushushu (50–100°C ephezulu kwi-HDT) ngokusebenzisa ukuhanjiswa komthwalo okusebenzayo. Ngokusekelwe kumxholo wefayibha, ezi composites ziqala kwi-fiber ephantsi (10%-20%), i-fiber ephakathi (25%-35%), i-fiber ephezulu (40%-50%), kunye ne-fiber ephezulu kakhulu (>50%). Umxholo wefayibha ongaphezulu kwe-30% uphucula kakhulu ukumelana nokuguguleka. Olu dibaniso luyenza ibe lolona khetho luphezulu kwizicelo zemizi-mveliso ezifuna amandla.

2. Ukuqinisa iFayibha yeKhabhoni:Ukongeza iifayibha zekhabhoni kwi-PA6/PA66 kuphucula kakhulu amandla oomatshini kunye nokumelana nokuguguleka. Ngokungafaniyo nezinye izinto zokuqinisa, ifayibha yekhabhoni ithambile kwaye ayinakurhawuzelelwa kakhulu, ithintela umonakalo kwiindawo ezichasene nesinyithi ngexesha lokungqubana. Amanqanaba aqhelekileyo okongezwa aqala kwi-5% ukuya kwi-20%, kunye nezicelo zokusebenza eziphezulu ezisebenzisa ukuya kuthi ga kwi-30%.

3. Ii-alloys ze-PTFE/PA6:Ngee-coefficients zokungqubana eziphantsi kakhulu, i-PTFE yenza iifilimu zokuthambisa ngexesha lokungqubana, nto leyo eyenza ukuba ifaneleke ngokukodwa kwizicelo zomthwalo ophezulu. Amanani aqhelekileyo okongezwa kwi-PA6 aqala kwi-15% ukuya kwi-20%.

4. Ii-Alloys zeMolybdenum Disulfide(MoS2)/PA66: Isebenza njengomkhuthazi we-crystallization, i-molybdenum disulfide yonyusa ubukhrista be-nylon, idala iindawo eziqinileyo nezinganyangekiyo. Ubudlelwane bayo obuphezulu neentsimbi buyivumela ukuba izalise ii-pores ezincinci kwiindawo zesinyithi, idala iindawo ezigudileyo. Oku kuyenza ilungele ukusetyenziswa kwe-nylon-metal friction, kunye namazinga aqhelekileyo okongezwa ukusuka kwi-3% ukuya kwi-15%.

5. I-PA66 eguqulwe yiGraphite:Izongezo zegrafiti zinciphisa ngempumelelo ii-coefficients zokungqubana ngelixa ziphucula iipropati zokuzithambisa. Ulwakhiwo oluneeleya zegrafiti luvumela ukutyibilika lula ngexesha lokungqubana, nto leyo enciphisa ukuguguleka. Olu tshintsho lusebenza ngakumbi kwiindawo zamanzi, kunye namazinga okongeza aqhelekileyo phakathi kwe-3% kunye ne-15%.

Imingeni Evelayo Ekuchaseni Ukunxitywa Kwe-Nylon: Ukulinganisela Ukusebenza, Ixabiso, kunye Nokuzinza

Nangona ezi zisombululo zisekiwe, abavelisi bebesoloko besokola ukulinganisela iimfuno zokusebenza ngokuchasene neendleko kunye neemfuno ezikhulayo zozinzo. Izongezo zemveli zihlala zifuna amanqanaba aphezulu okulayisha, nto leyo enokuchaphazela iimpawu zokucubungula kunye nokunyusa iindleko zezinto.

“Eli shishini belisoloko likhangela izisombululo ezinokunika ukumelana nokuguguleka okugqwesileyo ngaphandle kweengxaki ezinxulumene nezongezo zesiqhelo,” batsho abanye oonjineli bobunjineli bepolymer. “Isisombululo esifanelekileyo siya kufuna amaxabiso amancinci okongezwa ngelixa kugcinwa okanye kuphuculwa iimpawu zoomatshini bezinto ezisisiseko.”

UbuchuleIzisombululo zeplastiki zobunjineli zeNylon ezingagugiyo

I-Chengdu Silike Technology Co., Ltd. ibingumvelisi ophambili kunye nomvelisi wezongezo ze-silicone polymer ezisebenza kakuhle ukusukela ngo-2004. Sigxile kubuchwepheshe be-silicone kushishino lwerabha kunye neplastiki, sinikezela ngezixhobo zokucubungula ezisemgangathweni ezisombulula imingeni enzima yokuvelisa kunye nokuphucula iipropati zezinto ezisetyenziswa kwimizi-mveliso yehlabathi. Ukuphendula le mingeni, siye saphuhlisa i-isongezo esisebenza kakuhle kakhulu esisekelwe kwi-silicone esimelana nokuguguleka i-LYSI-704,yenzelwe ukuphucula ukuguqulwa kwe-nylon ngelixa ixhasa imveliso ezinzileyo.

Kutheni i-SILIKE Wear-Resistant Agent LYSI-704 itshintsha ukusebenza kweNylon? Yintoni eyenza i-LYSI-704 yahluke?

I-LYSI-704 anti wear additive entsha, esekelwe kwizakhiwo ze-polysiloxane ezenziwe ngokukodwa, ngokungafaniyo nezongezo zemveli ezimelana nokuguguleka, i-LYSI-704 ifikelela ekusasazekeni okufanayo kuyo yonke i-nylon matrices ngamanani aphantsi kakhulu okongezwayo. Oku kudala umaleko wokuthambisa oqhubekayo onciphisa kakhulu ii-coefficients zokungqubana ngelixa ugcina ukuthembeka koomatshini bezinto ezisisiseko.

“Okwenza obu buchwephesha bube nomtsalane kakhulu yindlela obusebenza ngayo ngeendlela ezininzi,” ucacisa njalo ingcali yophando nophuhliso evela kwi-SILIKE egxile ekusebenziseni i-silicone kwiiplastiki zobunjineli. “Xa idityaniswe kwiinkqubo zefayibha yeglasi ye-PA6+ ngokusebenzisa i-melt compounding, i-LYSI-704 ayiniki nje kuphela ukumelana nokuguguleka okugqwesileyo okufana nezisombululo ezisekelwe kwi-PTFE kodwa ikwaphucula amandla okuchaphazela - indibaniselwano eyayicingelwa ukuba ayinakwenzeka ngaphambili.

Mhlawumbi ingakumbi kubavelisi abajongene nobuhle, i-plastics additive/Modifier LYSI-704 ikwajongana nomba wokudada kwefayibha oqhubekayo oye wabangela iingxaki kwiinylon eziqiniswe ngeglasi, nto leyo evula amathuba amatsha okusetyenziswa apho umgangatho womphezulu ubaluleke kakhulu.

Ngaphezu koko, njengoko imiba yokuzinza iqhubeka nokutshintsha izigqibo zokukhetha izinto, ikhemistri esekwe kwi-silicone ye-LYSI-704 ibonelela ngenye indlela engena-fluorine kunezongezo ze-PTFE zendabuko, ihambelana namanyathelo ehlabathi okunciphisa ukusetyenziswa kweekhompawundi ezine-fluorinated. Amandla obu buchwephesha bokubonelela ngokusebenza okuphezulu ngamanani aphantsi okongeza akwathetha ukunciphisa ukusetyenziswa kwezixhobo kunye nokunciphisa impembelelo yekhabhoni kwinkqubo yokuvelisa.

Kubavelisi beplastiki zobunjineli abafuna iingenelo zokukhuphisana ngokusebenzisa izinto ezintsha, obu buchwepheshe bokuphucula ukongeza ukurhawuzelelwa obusekelwe kwi-silicone bubonelela ngamathuba anomdla kwimarike eyandayo, ngelixa bevula amathuba amatsha ophuhliso lwesicelo.

Ngaba ukulungele ukuphucula izinto zakho ze-nylon ngetekhnoloji entsha yokumelana nokuguguleka?

Ukuba ujongeizisombululo ezisebenzayo zokuphucula ukumelana nokuguguleka kwenayiloni yakhoizinto ezintsha ezifana ne-SILIKE LYSI-704 anti-wear additive signals turn through new material engineering, kwaye yindlela entsha obuyilindele. Inika indlela ehlala ihlelienye indlela endaweni yezongezo ze-PTFE zendabukoQhagamshelana nathi namhlanje ukuze ufumane indlela esi songezo kunye nesiguquli esitsha esinokuguqula ngayo iplastiki yakho yobunjineli ngelixa sihambelana neenjongo zakho zozinzo.

Tel: +86-28-83625089 or via Email: amy.wang@silike.cn. Website:www.siliketech.com

Ixesha lokuthumela: Meyi-22-2025