Iifilimu zeThermoplastic Polyurethane (TPU) zaziwa ngokuguquguquka kwazo okungaqhelekanga, ukuqina, kunye neempawu zazo zokusebenza okuphezulu, nto leyo eyenza ukuba zibe lukhetho olukhethwayo kumashishini afana neemoto, ezonyango, imfashini, kunye nezixhobo ze-elektroniki zabathengi. Ngelixa iifilimu zeTPU eziqhelekileyo zixatyiswa ngenxa yokumelana kwazo nokukrweleka kunye nozinzo lweekhemikhali, iifilimu zeTPU ezi-matte zifumana ukutsala okukhulu ngenxa yobuhle bazo, ukukhanya okuncinci, kunye neendawo ezinganyangekiyo zeminwe.

Nangona kunjalo, ukufumana ukugqitywa okusemgangathweni nokungaguquguqukiyo kweefilimu zeTPU kunokuba ngumceli mngeni. Imiba efana nokuthungwa okungalinganiyo, ukusasazeka kokukhanya okungalunganga, kunye neziphene zomphezulu zihlala zichaphazela abavelisi. Eli nqaku liphonononga iindlela zokulungiselela ezivunyiweyo zeefilimu zeTPU ezi-matte, ukujongana nemingeni ephambili kunye nokubonelela ngezisombululo ezisebenzayo ukukunceda uvelise iimveliso ezingenasiphako.

Iindlela zokulungiselela iMatte TPU Film

1. Ukukhethwa kweResin kunye nezongezo: Isiseko seMatte TPU Films

Uhambo lokudala iifilimu zeTPU ezikumgangatho ophezulu ezi-matte luqala ngokukhetha izixhobo ezifanelekileyo.

1.1 I-TPU Resin

Ukukhetha i-TPU resin efanelekileyo kubalulekile. Izinto ezibalulekileyo ekufuneka uziqwalasele ziquka:

Ukuqina: Iiresini eziphakathi ukuya kweziqinileyo zilungele ukugcina umgangatho uqinile ngelixa ziqinisekisa ukuguquguquka.

Ukuthamba: Ukuthamba okuphezulu kubalulekile kwimisebenzi efuna ukugoba okanye ukolula, njengezinto zangaphakathi zeemoto okanye izihlangu.

Ukuhambelana Kokucubungula: Qinisekisa ukuba i-resin iyahambelana nendlela oyikhethileyo yokucubungula (ukukhupha, ukuhlaziya, njl.njl.).

Eyona ndlela isebenzayo nesetyenziswa kakhulu yokwenza ifilimu ye-TPU e-matte kukudibanisa i-TPU kunye nezinye izongezo ezithile ezinciphisa ukukhanya kwaye ziyinike ukugqitywa oku-matte. Ezi zongezo, ezidla ngokubizwa ngokubaiiarhente zokugquma ,iimattifiersokanyeisongezo seTPU esingakhazimliyo,zifakwe kwi-TPU ngexesha lenkqubo yokudibanisa.izongezo ze-matt flattingukusebenza ngokuphazamisa umphezulu ogudileyo wefilimu, okukhokelela ekusasazekeni kokukhanya okubangela ukubonakala okungacacanga. Iindidi eziqhelekileyo zee-matting agents ziquka:

Ii-Matting Agents ezisekwe kwi-silica: Ezi ncindi ze-silica ezincinci ziphazamisa ukuguda komphezulu, zidala uburhabaxa obusasaza izibane.

Ii-Polymeric Matting Agents: Ezi arhente zihlala zifana ngakumbi kwaye zibonelela ngokusasazwa okungcono kwi-TPU matrix.

ICalcium Carbonate: Nangona ingasetyenziswa rhoqo njenge-silica okanye ii-polymeric agents, ingasetyenziswa kwezinye iindlela zokugqiba i-matte.

Icebiso Elihle: Ukuphucula Ukuqina Nokubhenela Okuncinci: Izisombululo zeMasterbatch ezisekelwe kwi-TPU ze-SILIKE

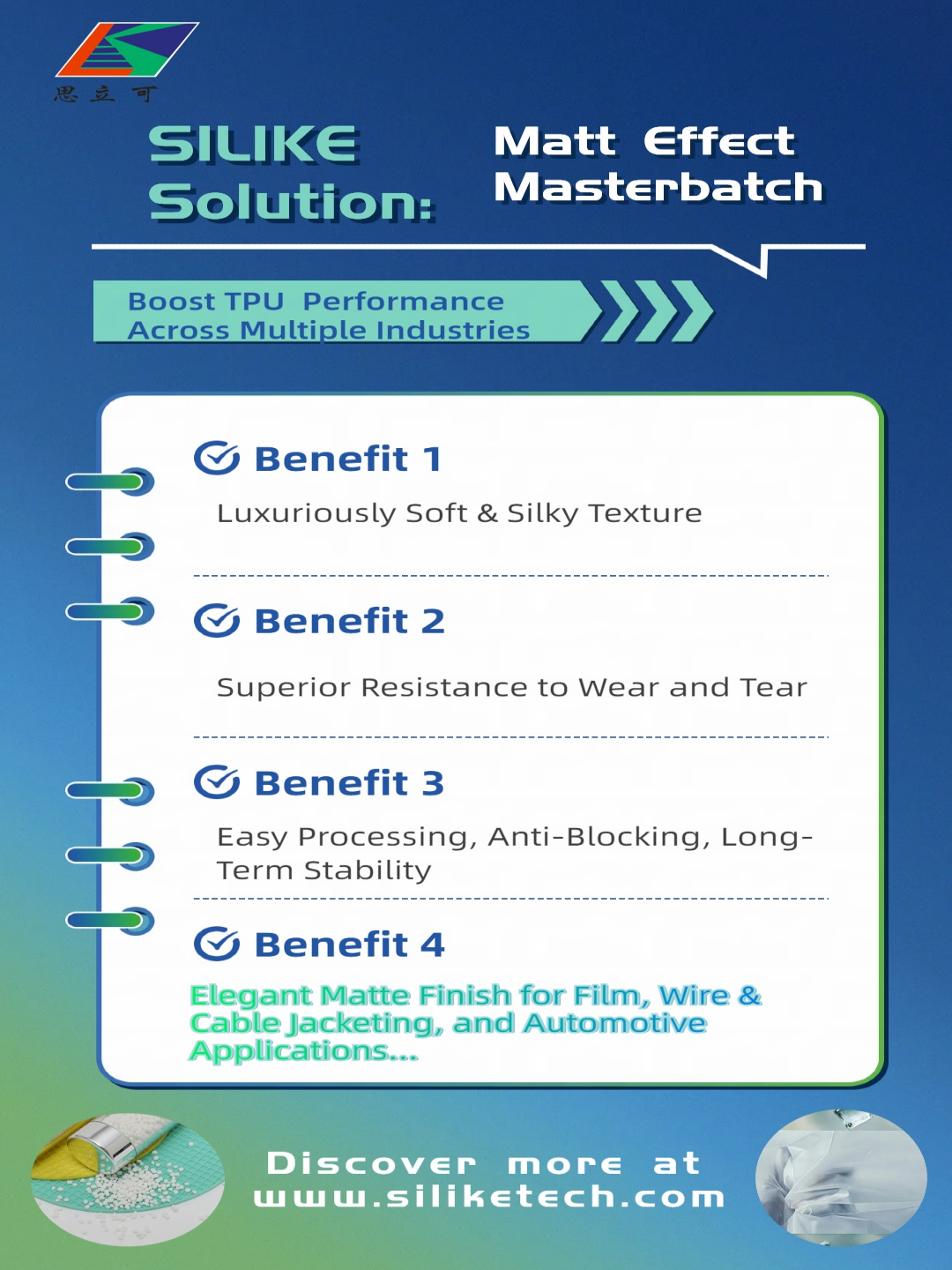

I-Matt Effect Masterbatchyi-Matting Agent entsha eyenziwe yi-SILIKE, isebenzisa i-thermoplastic polyurethane (TPU) njengesithwali sayo. Ihambelana ne-TPU esekelwe kwi-polyester kunye ne-polyether, le arhente ye-matting yenzelwe ukuphucula imbonakalo ye-matte, ukuchukumisa umphezulu, ukuqina, kunye neempawu zokungathinteli iifilimu ze-TPU kunye neemveliso zazo zokugqibela.

Eyona nto iphambiliI-SILIKE's Polyester TPU-based kunye ne-Polyether TPU-based Matt Effect Masterbatch lilula—inokufakwa ngokuthe ngqo ngexesha lokucubungula, isusa isidingo se-granulation, kwaye iqinisekisa ukuba akukho mngcipheko wemvula nokuba isetyenziswa ixesha elide.

Ifanelekile kwiizicelo ezifuna ukugqitywa kwe-matte ephezulu, njengeefilimu zeTPU ezisetyenziswa ekupakisheni, kwiimoto, kwizihlangu, kwizixhobo zonyango, nakwii-elektroniki zabathengi.

Ingakumbi,I-Matt Effect Masterbatch 3235ilungele ukwenza isiphelo se-TPU se-polyester esingcono kakhulu sokufaka izinto zokupakisha.

1.3 Izongezo ezongezelelweyo

Ukuze uphucule ukusebenza, cinga ngokubandakanya:

Izinto Ezithintela Ukuvalwa Kwefilimu Zithintela iifilimu ukuba zinganamatheli kunye ngexesha lokugcina.

IziQinisekisi ze-UV: Zikhusela ekuwohlokeni kwe-UV, zilungele ukusetyenziswa ngaphandle.

Izinto zokutyibilika: Phucula iipropati zokutyibilika komphezulu ukuze kube lula ukuyiphatha.

2. Inkqubo yokukhupha: Ukuchaneka kubalulekile

Ukukhupha iifilimu zeTPU yeyona ndlela ixhaphakileyo yokwenza iifilimu zeTPU. Ukuze ufumane ukugqitywa okugqibeleleyo kwe-matte:

2.1 I-Extruder enamaqhosha amabini

I-extruder enezikrufu ezimbini iqinisekisa ukuxubana okungcono kunye nokusasazeka kwee-matting agents, nto leyo ebangela ukuba ibonakale ifana kakhulu.

2.2 Ulawulo lobushushu

Gcina ulawulo oluchanekileyo lobushushu ukuze uphephe iziphene zomphezulu ezifana namaqamza, imicu, okanye ukukhanya okungalinganiyo.

2.3 Uyilo lweDie

Sebenzisa i-flat die ene-matte surface finish okanye ufake i-textured chill roll ukuze unike umphezulu owufunayo ubume obufunekayo.

3. Iindlela Zonyango Lomphezulu: Ukuphucula Isiphumo Esimantla

Unyango lomphezulu lunokuphucula ngakumbi ukugqitywa kwe-matte kwaye luphucule ukusebenza:

3.1 Ukwaleka

Faka i-matte coating usebenzisa iindlela zokusonga okanye zokutshiza ukuphucula ubume bomphezulu ngaphandle kokutshintsha ulwakhiwo lwe-TPU.

3.2 Ukuzoba imifanekiso

Dlulisa ifilimu kwiirola ezihombisayo ezinesitayile esingacwebezeliyo ukuze wenze ipateni ephakanyisiweyo ukuze ugqibezele kakuhle.

3.3 Ukukrola iikhemikhali

Sebenzisa unyango oluthambileyo lweekhemikhali ukuze utshintshe uburhabaxa bomphezulu, ukuze ufumane uburhabaxa obufanayo obungacwebezeliyo xa usetyenziswa ngokuchanekileyo.

4. Inkqubo yeFilimu ephuphumayo vs. Abadlali: Ukukhetha indlela eyiyo

Ukukhetha phakathi kweenkqubo zefilimu eziqhumayo kunye nezefilimu ezibunjiweyo kuxhomekeke kwiimpawu zefilimu ozifunayo:

4.1 Inkqubo yeFilimu evuthayo

Ilungele iifilimu ezityebileyo, inkqubo yefilimu evuthuziweyo isebenzisa ukupholisa umoya ukuze ifumane ukugqitywa kwendalo okuthambileyo.

4.2 Inkqubo yeFilimu yabalingisi

Eyona ilungele iifilimu ezincinci, inkqubo yefilimu yabadlali isebenzisa i-textured chill roll ukwenza ukugqitywa okufana nokungaguquguqukiyo nokumgangatho ophezulu.

5. Iindlela Zokuhlela Emva Kokucubungula: Ukugqiba Ukugqiba

Ukucubungula emva kokucoca kunokuphucula isiphumo se-matte kwaye kuphucule ukusebenza kwefilimu:

5.1 Ukubhala iikhalenda

Dlulisa ifilimu kwiirola zekhalenda ukuze ulungise ubume bomphezulu kunye nobukhulu, uqinisekise ukuba igqibelele ngendlela efanayo.

5.2 Ukufakelwa kwelamination

Bopha ifilimu ye-TPU engacwebezeliyo nezinye izinto ukuze womeleze amandla, ukuqina, okanye iimpawu zokuthintela ngelixa ugcina imbonakalo engacwebezeliyo.

5.3 Ukutshixa Umphezulu

Sebenzisa ukukrala koomatshini ukuze uphucule ubume obungacwebezeliyo, udale ukugqitywa komphezulu okulinganayo kwizicelo eziphezulu.

Isikhokelo seMatte TPU Films: I-Matt Effect Masterbatch kaSILIKE iyazisa

I-SILIKE'sI-Matt Effect Masterbatchinikeza isisombululo esithembekileyo nesisebenzayoukuvelisa iifilimu zeTPU ezikumgangatho ophezulu ze-matte.Ngokulula ukuyidibanisa ngexesha lokucubungula kunye nokuzinza kwexesha elide, lukhetho olufanelekileyo kubavelisi abafuna ukuphakamisa iimveliso zabo.

Ngaba unengxaki nge-TPU Film Gloss? Okanye, ukulungele ukufezekisa iiPremium Matte Finish kwiMveliso yakho yeFilimu ye-TPU?

Nxibelelana ne-SILIKE—umenzi we-Matte Effect Masterbatch oyingcali— ukuze ufunde okungakumbi ngezinto ezintshaIzisombululo zeTPU Matt Effect Masterbatchkwaye ucele isampuli yeeAnti-blocking Matte Effect Additives zethu!

Umnxeba: +86-28-83625089,Email: amy.wang@silike.cn, Iwebhusayithi: www.siliketech.com

Ixesha leposi: Matshi-05-2025