Izinto ezisetyenziswa kwiplastiki yengxowa yempahla ziquka oku kulandelayo, kwaye izibonelelo kunye neziphene zazo zezi zilandelayo:

1.PE (i-polyethylene):

Iingenelo: ukuqina okuhle, ukungoyiki ukukrazuka, ukumelana nokutsalwa, amandla okuthwala, ukumelana nokuguguleka, akukho lula ukuphula, isempilweni kwaye iqinisekile, ukutya kuyafumaneka, ukuvala kakuhle.

Iziphene: Akukho kukhanya kucacileyo, inkungu ephezulu, ixabiso liphezulu.

2. I-PP (iPolypropylene):

Iingenelo: ukukhanya okuphezulu, ukhuseleko oluvaliweyo, akukho loyiko lokubola, ingasetyenziswa ngokuphindaphindiweyo.

Isiphene: Uxinzelelo alulunganga kangako, kulula ukuluphelisa.

3. Izinto ze-OPP (i-polypropylene esekwe kwi-Oriented):

Iingenelo: ukucaca okuphezulu, ukutywinwa okuhle.

Iziphene: ukuxinana akwanelanga, kulula ukuphula, kwaye ukuprinta yeyona ndlela ilula ukuyisusa umbala.

4. I-PVC (i-polyvinyl chloride):

Iingenelo: ukhuseleko nempilo, ihlala ixesha elide kwaye intle kwaye iyasebenza, imilo entle, izitayile ezahlukeneyo.

Iziphene: ukhuseleko oluphantsi kokusingqongileyo, oluqulethe i-chlorine, ukutsha kuya kuvelisa iigesi eziyingozi.

Ifilimu yengxowa yempahla yeplastiki yezinto ezingentla ineempawu zayo, kwaye ukhetho lunokusekelwa kwiimfuno ezithile kunye nokuqwalasela iindleko, ukhuseleko lokusingqongileyo kunye nezinye izinto zokugqiba ukuba zeziphi izinto ekufuneka zisetyenziswe. Ingxowa yengubo yimveliso "yengubo", ukongeza ekuhombiseni ukupakisha, eyona nto ibalulekileyo kukudlala ukupakisha okuzimeleyo, indawo yokugcina, ukhuseleko njalo njalo. Okukhona impahla ithambile, kokukhona ifuna ukhuseleko lwengxowa yokupakisha, ukuze kuthintelwe ukuba impahla ingonakalisa okanye idibane nothuli nezinye izinto ezingcolileyo.

Ke ngoko, iingxowa zempahla zibalulekile kwishishini lempahla. Nangona kunjalo, ifilimu yokupakisha impahla kulula ukuyifumana kwinkqubo yokusetyenziswa kunye nokuthutha: i-coefficient yokungqubana kwengxowa yempahla ayizinzanga, imvula yomgubo ingcolise impahla kunye nezinye iingxaki.

Izongezo ze-SILIMER ezingadubuliyoSombulula ingxaki yokufuduka komgubo kwifilimu yebhegi yempahla

Uphuhliso lweIzongezo ze-super slip ze-SILIKE SILIMER ezingafudukiyoyintsha kwifilimu yeengxowa zempahla. Yahlukile kwiarhente yokuthambisa yendabuko enobunzima obuphantsi beemolekyuli, iarhente yokutyibilika ye-SILIMER engaqhakaziyo yimveliso entsha ye-polysiloxane eguqulweyo. Iimolekyuli zayo ziqulathe zombini iinxalenye zeetyathanga ze-polysiloxane kunye namaqela asebenzayo aneetyathanga zekhabhoni ezinde. Iityathanga zekhabhoni ezinde ziyahambelana neeresini ukuze zidlale indima yokubambelela, kwaye iityathanga ze-silicon zihlukaniswe kumphezulu wefilimu ukuze zidlale indima yokuthambisa. Ukuze idlale indima egudileyo ngaphandle kokuna ngokupheleleyo, ukusuka kwingcambu ukuya kusombululo lwengxaki yengxowa yeempahla ifilimu yokuthambisa uthuli, ungcoliseko lwempahla.

Ezi zilandelayo ziingenelo zeI-SILIKEI-masterbatch yearhente yokutyibiliza engangenisi mvula ye-SILIMER ekusebenziseni ifilimu yengxowa yempahla:

Ihlala ixesha elide igudile, ingenamvula, ipowder:iphucula kakhulu ukuguda, inciphise i-dynamic and static friction coefficient, ihlale iguda ngaphandle kwemvula, ukuze kuthintelwe ukungcola kwempahla okubangelwa yi-precipitation powder.

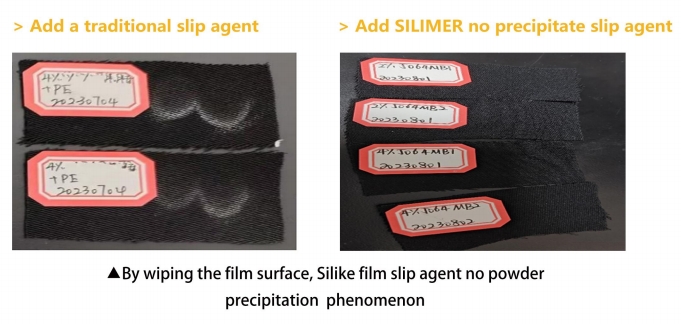

Njengoko kubonisiwe kumfanekiso ongezantsi, umphezulu wefilimu une-arhente yendabuko yokuthambisa iimolekyuli ezisezantsi kunye nomphezulu oneSILIKE SILIMER non-Blooming arhente yokutyibilikazasulwa ngelaphu elimnyama. Kuyabonakala ukuba xa kuthelekiswa nokusetyenziswa kwezongezo zemveli ezisezantsi kweemolekyuli,Izongezo zeSILIKE SILIMER ezingafudukiyoayikhawulezisi isiphumo sempuphu.

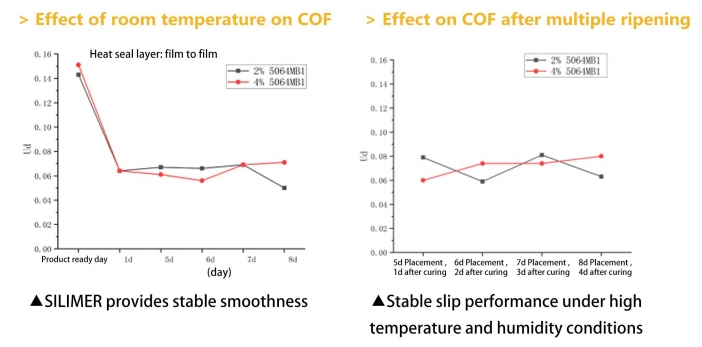

Ukumelana nobushushu obuphezulu, i-coefficient yokungqubana okuzinzileyo:ukumelana okuhle nobushushu obuphezulu, ukuhambelana okuhle kakhulu ne-matrix resin, akuyi kubangelwa kukugcinwa kobushushu obuphezulu, ukuthuthwa okanye utshintsho lobushushu, olufana nomlinganiselo wokungqubana ongagudiyo, ongagungqiyo kunye nezinye iimeko.

Njengoko kubonisiwe ngezantsi, iimeko zokuphilisa: ubushushu obuyi-45℃, ukufuma okungu-85%, ixesha leeyure ezili-12, amaxesha ama-4.

Imveliso izinzile kwi-COF emva konyango oluphezulu nolunomswakama ophezulu, ifilimu ilungiselelwe umthengi, iileya ezintlanu zefilimu evuthuziweyo, ubukhulu bayo buyi-100 microns. Kuyabonakala ukuba emva kokusetyenziswaIzongezo ze-SILIKE SILIMER ezingezizo ezokuthutha ezisetyenziswa kwi-super slip, ifilimu inokumelana okuhle nobushushu obuphezulu kunye ne-coefficient eqinileyo yokungqubana.

Umswakama ophantsi:ayichaphazeli ukusetyenziswa kwemiboniso efuna ukucaca.

Uzinzo oluphezulu:ayichaphazeli ukuprinta, i-composite kunye nokunye ukucutshungulwa okulandelayo.

Isetyenziswa kakhulu:ingasetyenziswa kwi-BOPP, CPP, PE, PP nakwezinye iifilimu.

Ukuphucula ukusebenza kokucubungula kunye neempawu zomphezulu wefilimu, ukubonelela ngokugudileyo kobushushu obuphezulu bexesha elide, kuphephe i-powder yemvula, sinamava amaninzi kunye namatyala amaninzi aphumelelayo, ukuba ufuna izisombululo ezinxulumene nokuguqulwa kwezinto, nceda unxibelelane ne-SILIKE!

I-Chengdu SILIKE Technology Co., Ltd, inkokheli yaseTshayinaIsongezo seSiliconeUmboneleli weplastiki eguquliweyo, unikezela ngezisombululo ezintsha zokuphucula ukusebenza kunye nokusebenza kwezixhobo zeplastiki. Wamkelekile ukuba unxibelelane nathi, i-SILIKE iza kukunika izisombululo ezisebenzayo zokucubungula iplastiki.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn.

iwebhusayithi:www.siliketech.comukuze ufunde okungakumbi.

Ixesha lokuthumela: Novemba-05-2024