I-color masterbatch yeyona ndlela ixhaphakileyo yokufaka imibala kwiplastiki, esetyenziswa kakhulu kushishino lokucubungula iiplastiki. Enye yezona mpawu zibalulekileyo zokusebenza kwe-masterbatch kukusasazeka kwayo. Ukusasazeka kubhekisa kukusasazwa okufanayo kwe-colorant ngaphakathi kwezinto zeplastiki. Nokuba kukubumba ngenaliti, ukukhupha, okanye iinkqubo zokubumba nge-blow, ukusasazeka okungalunganga kunokukhokelela ekusasazweni kombala okungalinganiyo, imicu engaqhelekanga, okanye amabala kwimveliso yokugqibela. Le ngxaki yinkxalabo ebalulekileyo kubavelisi, kwaye ukuqonda izizathu kunye nezisombululo kubalulekile ekugcineni umgangatho wemveliso.

Izizathu zokusasazeka kakubi kwi-Color Masterbatch

Ukuhlanganiswa kweePigments

I-Masterbatch yindibaniselwano exutywe kakhulu yee-pigment, kwaye amaqela amakhulu ezi pigment anokuchaphazela kakhulu ukusasazeka. Ii-pigment ezininzi, ezifana ne-titanium dioxide kunye ne-carbon black, zihlala zihlangana. Ukukhetha uhlobo olufanelekileyo kunye nobukhulu bee-particle ze-pigment ngokwemveliso yokugqibela kunye nendlela yokucubungula kubalulekile ukuze kufezekiswe ukusasazeka okuhle.

Iziphumo ze-Electrostatic

Ii-masterbatches ezininzi azibandakanyi ii-antistatic agents. Xa i-masterbatch ixutywe nezinto eziluhlaza, umbane ongashukumiyo unokuveliswa, nto leyo ekhokelela ekuxubeni okungalinganiyo kunye nokusasazwa kombala okungaguqukiyo kwimveliso yokugqibela.

Isalathisi sokunyibilika esingafanelekanga

Abathengisi badla ngokukhetha iiresini ezine-melt index ephezulu njengomthwali we-masterbatch. Nangona kunjalo, i-melt index ephezulu ayisoloko ingcono. I-melt index kufuneka ikhethwe ngononophelo ukuze ihambelane neempawu zomzimba kunye neemfuno zomphezulu wemveliso yokugqibela, kunye neempawu zokucubungula ze-masterbatch. I-melt index ephantsi kakhulu inokubangela ukusasazeka okubi.

Umlinganiselo ophantsi wokongeza

Abanye abathengisi bayila i-masterbatch enomlinganiselo ophantsi wokongeza ukuze banciphise iindleko, nto leyo enokubangela ukuba imveliso ingasasazeki ngokwaneleyo.

Inkqubo yokuSasazwa engonelanga

Ii-arhente zokusasaza kunye nee-lubricants zongezwa ngexesha lenkqubo yokuvelisa i-masterbatch ukunceda ekuqhekezeni amaqela e-pigment. Ukuba kusetyenziswa ii-arhente zokusasaza ezingalunganga, oku kunokukhokelela ekusasazekeni okubi.

Ukungalingani koxinano

IiMasterbatches zihlala ziqulathe imibala enobunzima obuphezulu, efana ne-titanium dioxide, enobunzima obumalunga ne-4.0g/cm³. Oku kuphezulu kakhulu kunobunzima beeresini ezininzi, nto leyo ekhokelela ekuqhekekeni kwe-masterbatch ngexesha lokuxuba, nto leyo ebangela ukusasazwa kombala okungalinganiyo.

Ukukhetha Umthwali Okungafanelekanga

Ukukhethwa kwe-carrier resin, egcina imibala kunye nezongezo, kubaluleke kakhulu. Izinto ezifana nohlobo, ubungakanani, inqanaba, kunye ne-melt index ye-carrier, kunye nokuba ingaba yi-powder okanye i-pellet, zonke ezi zinto zinokuchaphazela umgangatho wokugqibela wokusasazeka.

Iimeko Zokucubungula

Iimeko zokucubungula i-masterbatch, kuquka uhlobo lwezixhobo, iinkqubo zokuxuba, kunye neendlela zokufaka iipelletizing, zidlala indima ebalulekileyo ekusasazekeni kwayo. Ukhetho olufana noyilo lwezixhobo zokuxuba, ulungiselelo lwezikrufu, kunye neenkqubo zokupholisa zonke zichaphazela ukusebenza kokugqibela kwe-masterbatch.

Impembelelo yeNkqubo yokuBumba

Inkqubo ethile yokubumba, efana nokubumba ngenaliti, inokuchaphazela ukusasazeka. Izinto ezifana nobushushu, uxinzelelo, kunye nexesha lokubamba zinokuchaphazela ukufana kokusasazwa kombala.

Izixhobo zokunxiba

Izixhobo ezisetyenziswa ekubumbeni iplastiki, ezifana nezikrufu ezigugileyo, zinokunciphisa amandla okucheba, zenze buthathaka ukusasazeka kwe-masterbatch.

Uyilo lweMold

Kwi-injection molding, indawo yesango kunye nezinye iimpawu zoyilo lwe-mold zinokuchaphazela ukwakheka kwemveliso kunye nokusasazwa kwayo. Kwi-extrusion, izinto ezifana noyilo lwe-die kunye noseto lobushushu nazo zinokuchaphazela umgangatho wokusasazeka kwayo.

Izisombululo Zokuphucula Ukusasazeka kwi-Color Masterbatch, imibala exutyiweyo kunye neekhompawundi

Xa ujongene nokusasazeka okubi, kubalulekile ukujongana nengxaki ngendlela ecwangcisiweyo:

Sebenzisana kuzo zonke iinkalo: Rhoqo, imiba yokusasazeka ayibangelwa kuphela zizinto eziphathekayo okanye izinto zenkqubo. Intsebenziswano phakathi kwabo bonke abachaphazelekayo, kuquka ababoneleli bezinto eziphathekayo, iinjineli zeenkqubo, kunye nabavelisi bezixhobo, ibalulekile ekuchongeni nasekulungiseni izizathu eziphambili.

Lungiselela uKhetho lwePigment:Khetha imibala enobukhulu obufanelekileyo bezinto kunye nohlobo oluhambelana nosetyenziso oluthile.

Ulawulo loMbane oNgaguqukiyo:Faka izinto ezilwa nokungalinganiyo apho kuyimfuneko khona ukuze kuthintelwe ukuxubana okungalinganiyo.

Lungisa i-Melt Index:Khetha abathwali abane-melt index ehambelana neemeko zokucubungula kunye neemfuno zemveliso.

Uphononongo lweeRatio zokongezaQinisekisa ukuba i-masterbatch yongezwa ngobuninzi obaneleyo ukuze kufunyanwe ukusasazeka okufunekayo.

Lungisa Inkqubo Yokusasaza:Sebenzisa izinto zokunyibilikisa kunye nezinto zokuthambisa ezifanelekileyo ukuphucula ukuqhekeka kwee-pigment agglomerates.

Ubuninzi boMfanekiso:Cinga ngobuninzi beepigment kunye nee-carrier resins ukuze uphephe ukubola kwenkunkuma ngexesha lokucubungula.

Iiparameter zokuCwangcisa kakuhle:Lungisa useto lwezixhobo, ezifana nobushushu kunye noqwalaselo lwezikrufu, ukuze kuphuculwe ukusasazeka kwazo.

UbuchuleIzisombululo Zokuphucula Ukusasazeka kwi-Color Masterbatch

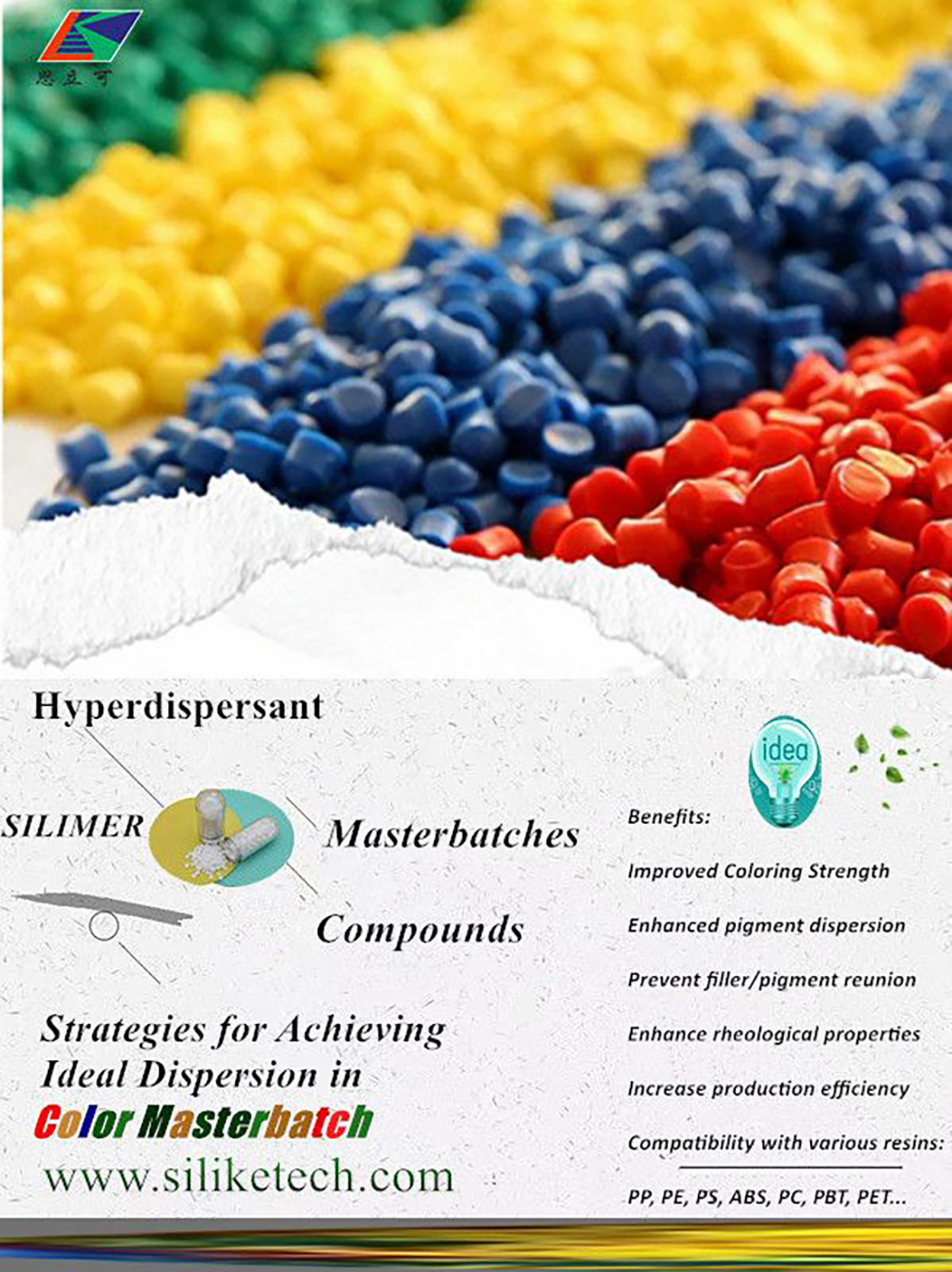

I-Novel Silicone hyperdispersant, indlela esebenzayo yokusombulula i-Uneven Dispersion kwi-Color Masterbatches ngeI-SILIKE SILIMER 6150.

I-SILIMER 6150yi-wax ye-silicone eguquliweyo esebenza njenge-hyperdispersant esebenzayo, eyilelwe ngokukodwa ukuphucula umgangatho we-color concentrates, i-masterbatches, kunye nee-compounds. Nokuba yi-single pigment dispersion okanye i-color concentrates eyenzelwe wena, i-SILIMER 6150 igqwesile ekuhlangabezaneni neemfuno ze-dispersion ezifuna kakhulu.

Aiingenelo ze I-SILIMER 6150kwizisombululo ze-color masterbatch:

Ukusasazwa kwePigment okuphuculweyo: I-SILIMER 6150iqinisekisa ukusasazwa okufanayo kweepigment kwi-matrix yeplastiki, isusa imicu okanye amabala emibala kwaye iqinisekisa ukuba imibala iyafana kuyo yonke into.

Amandla Okufaka Umbala Aphuculweyo:Ngokuphucula ukusasazeka kwemibala,I-SILIMER 6150iphucula amandla ombala ngokubanzi, ivumela abavelisi ukuba bafikelele kubunzulu bombala obufunekayo ngepigment encinci, nto leyo ekhokelela kwimveliso esebenza kakuhle nengabizi kakhulu.

Ukuthintela ukuhlanganiswa kweFiller kunye nePigment: I-SILIMER 6150ithintela ngokufanelekileyo imibala kunye nezizalisi ekudibaneni, iqinisekisa ukusasazeka okuzinzileyo nokungaguquguqukiyo kulo lonke ixesha lokucubungula.

Iimpawu ezingcono ze-Rheological: I-SILIMER 6150Ayiphuculi nje kuphela ukusasazeka kodwa ikwaphucula neempawu ze-rheological ze-polymer melt. Oku kubangela ukucutshungulwa okuthambileyo, ukunciphisa i-viscosity, kunye neempawu zokuhamba kwamanzi eziphucukileyo, ezibalulekileyo kwimveliso yeplastiki esemgangathweni ophezulu.

IUkonyuka kokusebenza kakuhle kwemveliso kunye nokuncitshiswa kweendleko: Ngokusasazeka okuphuculweyo kunye neempawu ezingcono ze-rheological,I-SILIMER 6150kwandisa ukusebenza kakuhle kwemveliso, okuvumela amaxesha okucubungula akhawulezileyo kunye nokunciphisa inkunkuma yezinto, ekugqibeleni kunciphisa iindleko zemveliso iyonke.

Ukuhambelana okubanzi: I-SILIMER 6150iyahambelana noluhlu olubanzi lweeresini, kuquka iPP, iPE, iPS, iABS, iPC, iPET, kunye nePBT, nto leyo eyenza ukuba ibe lukhetho olufanelekileyo kwiintlobo ngeentlobo zezicelo kwishishini le-masterbatch kunye neeplastiki ezidityanisiweyo.

Phucula imveliso yakho ye-color masterbatch ngeI-SILIMER 6150ukuze ufumane umbala osasazekileyo kunye nokusebenza kakuhle kwemveliso. Susa imicu yemibala kwaye wonyuse ukusebenza kakuhle. Ungaphoswa—phucula umbala osasazekileyo, wehlise iindleko, kwaye unyuse umgangatho we-masterbatch yakho.Qhagamshelana noSilike namhlanje!Umnxeba: +86-28-83625089, I-imeyile:amy.wang@silike.cn,Ndwendwelawww.siliketech.comukuze ufumane iinkcukacha.

Ixesha leposi: Agasti-15-2024