Kutheni i-Heat Seal yePlastiki yakho ibuthathaka? Izizathu ezi-4 zokungaphumeleli kokutywinwa kwePlastiki kunye nezisombululo eziqinisekisiweyo ezivela kwi-SILIKE

Intshayelelo: Ixabiso Elifihlakeleyo Lokuqina Kwesitywina Sobushushu Obungebuhle

Kwimveliso yanamhlanje yokupakisha, izitywino zobushushu ezibuthathaka okanye ezingaguquguqukiyo zihlala zizezona ngxaki zixhaphakileyo kodwa ezibiza kakhulu.

Idatha yoshishino ibonisa ukuba phantse i-30% yazo zonke izikhalazo zomgangatho wokupakisha zinxulumene nokungasebenzi kakuhle kwetywina lobushushu. Isiphumo? Inkunkuma yezinto eziphathekayo, ukusebenza okuphantsi komgca, kunye nemiphumo emibi efana nokuvuza kwemveliso, ukuncipha kwexesha lokuphelelwa, okanye ukubuyiselwa kwemali ngabathengi.

Ngaphezulu kweminyaka engama-20 yobuchwephesha kwiizongezo ezisebenzayo ezisekelwe kwi-silicone,I-SILIKE isebenzisane nabavelisi beefilimu abaphambili ukuchonga, ukuhlalutya, nokusombulula izizathu ezifihlakeleyo ezibangela ukusebenza kakubi kokutywina. Masifumanise isayensi engasemva kwayo - kwaye sihlolisise izisombululo eziqinisekisiweyo.

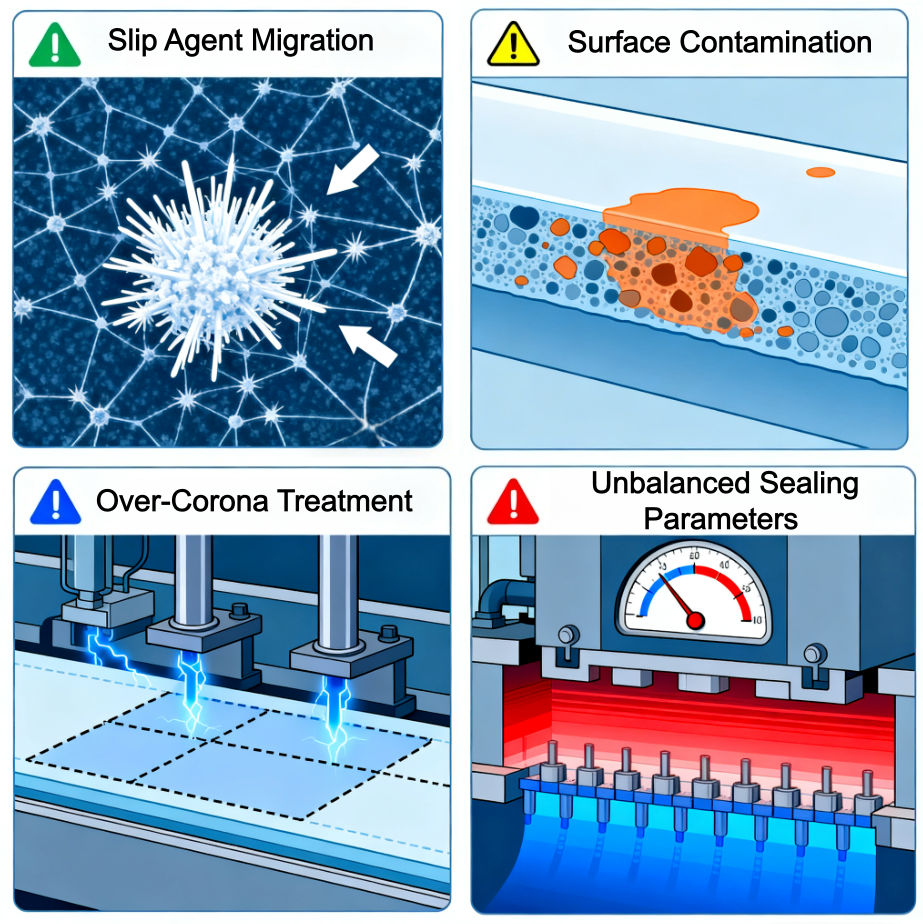

I. Izizathu Ezine Ezibangela Ukungaphumeleli Kwesitywina Sobushushu Kwimveliso Yokupakisha

1. Ukufuduka kwe-Slip Agent — Umqobo ongabonakaliyo kwiiSeal zobushushu eziqinileyo

Esinye sezizathu ezingathathelwa ngqalelo zokuba amandla okuvala ubushushu angabi mahle kukufuduka kwezinto ezityibilikayo.

Ii-slip agents ezisekelwe kwi-amide ezifana ne-erucamide okanye i-oleamide ziyahamba kancinci kancinci ziye kumphezulu wefilimu ngexesha lokugcina nokucubungula.

Icacisiwe Indlela Yokusebenza:

Iimolekyuli ezifudukayo zenza ifilimu yokuthambisa enomgangatho omnye okanye omninzi phezu komhlaba.

Olu maleko mncinci luyazahlula ngokwasemzimbeni iindawo zokutywina.

Nangona inciphisa ukungqubana (okuphucula ukuphathwa kwefilimu), ikwanciphisa ukubopha kweemolekyuli phakathi kweengqimba ngexesha lokutywina.

Iimolekyuli ezincinci ziphazamisana nokusasazeka kwetyathanga lepolymer kunye nokuxinana kwindawo yokutywina.

Izifundo zibonisa ukuba xa ukufuduka kwe-slip agent kudlula i-15 mg/m², amandla okuvala ubushushu anokwehla ukuya kuthi ga kwi-50%.

Yiyo loo nto abavelisi beefilimu banamhlanje betshintshela kwiinkqubo zokongeza ukutyibilika ezingadubuliyo — ukuqinisekisa ukusebenza okuhlala ixesha elide kokutyibilika ngaphandle kokufuduka komphezulu.

2. Ungcoliseko Lomphezulu — Xa Ucinga Ukuba Ucocekile, Kodwa Ungenjalo

Kwanezinto ezingabonakaliyo ezingcolisayo ezifana nothuli, ukufuma, okanye ioyile eseleyo zinokusebenza “njengomaleko wokuzihlukanisa” ongabonakaliyo, nto leyo ethintela ukutywinwa okusebenzayo.

Imeko eziqhelekileyo ziquka:

Ukucocwa kwezikrufu okungaphelelanga kwifilimu ephumayo, okukhokelela kwiinkcenkce ezifakwe i-carbon.

Inkungu yeinki evela kwimigca yokuprinta engcolisa indawo yokutywina.

Iingcebiso zokuthintela:

Misela imigangatho yokucoceka kweefilimu kunye nokuhlolwa rhoqo.

Lawula umswakama kunye namasuntswana ahamba emoyeni kwindawo yemveliso.

Yenza uhlolo lokungena kwezinto eziluhlaza ukuze kuqinisekiswe ukuba ifilimu isemgangathweni ofanayo.

3. Unyango Olungaphaya KweCorona — Xa Ukwenziwa Ngcono Kujika Kube Konakaliseyo

Unyango lweCorona lusetyenziswa kakhulu ukuphucula amandla omphezulu wefilimu ukuze kuqiniswe ngcono. Nangona kunjalo, unyango olugqithisileyo lunokuba nefuthe elichaseneyo.

Unyango olugqithisileyo lunokubangela:

Ukuqhekeka kwetyathanga lepolymer kunye nokwenziwa kweengqimba zomda ezibuthathaka.

I-oxidation egqithisileyo, ivelisa iikhompawundi ezinobunzima obuphantsi beemolekyuli.

Imingxunya emincinci ethintela ukuthembeka kwesitywina.

Ingcebiso yengcali: Kwiifilimu ezisekelwe kwi-PE, gcina umgama we-corona phakathi kwama-38–42 dynes/cm ukuze ufezekise ukusebenza okuzinzileyo ngaphandle kokuwohloka komphezulu.

4. IiParamitha zokutywina ezingalinganiyo — “Unxantathu weGolide” woBushushu, uxinzelelo, kunye nexesha

Ukuvala ubushushu ngokusisiseko yinkqubo yokunyibilikisa nokubuyisela imixokelelwane ye-thermoplastic phantsi kweemeko ezilawulwayo.

Xa ubushushu, uxinzelelo, kunye nexesha lokuhlala zingalingani kakuhle, neefilimu ezikumgangatho ophezulu aziyi kuvala kakuhle.

Isisombululo seSayensi:

Yakha isiseko sedatha sepharamitha kwibakala ngalinye lefilimu, qinisekisa rhoqo ukuvala iifestile, kwaye usebenzise ukulandelwa kwerekhodi yedijithali ukuqinisekisa ukuba inkqubo iyaphindaphindeka.

II. Izisombululo zeSILIKE eziQinisekisiweyo zokuqinisa isitywina sobushushu esithembekileyo

Ngeminyaka yophando olusetyenzisiweyo kwizinto zokupakisha, i-SILIKE ibonelela ngezisombululo ezidibeneyo zokunceda abavelisi beefilimu ukuba boyise ukusilela kokutywina - ukusuka ekuveliseni izinto ezintsha ukuya ekuphuculeni inkqubo.

ZethuI-SILIMER Series Super Slip Masterbatchimele isizukulwana esitsha seizongezo zokutyibilika ezingafudukiyo kunye nezongezo ezichasene neebhloko, yenzelwe ukuphelisa ukudumba komphezulu kunye nokuna kwempuphu ngelixa igcina ukusebenza kakuhle kwefilimu. Inika ukuvalwa kobushushu rhoqo, iipropati ezingafudukiyo, kunye nokugqitywa komphezulu okugqwesileyo kwiingxowa zeplastiki.

Iingenelo eziphambili zeIzongezo zeSILIMER Series Super Slip kunye ne-Anti-Blocking

• Iphelisa iingxaki zomgubo

Ithintela ukufuduka kwee-agent ezityibilikayo kwaye isombulula ngokupheleleyo ingxaki eqhelekileyo yokuna kwempuphu emhlophe kwiindawo zefilimu.

•Ukusebenza okungapheliyo kokutyibilika

Igcina i-coefficient ezinzileyo nephantsi yokungqubana kuyo yonke i-film lifecycle.

•I-Anti-Blocking Ephezulu

Iphucula ukusebenza kakuhle kokuphathwa kwefilimu kwaye ithintela ukuba iileya zinganamatheli kunye ngexesha lokusonga okanye lokugcina.

•Ukuphuculwa koBuchule bomphezulu

Inika umphezulu ocwebezelayo, ofanayo ukuze ibonakale intle kwaye ibe nomgangatho ongcono wokuchukumisa.

•Akukho Kuvumelana kwiipropati zeFilimu

Iqinisekisa ukuba ukuprinta okugqwesileyo, ukuvala ubushushu, ukugquma, ukucaca, kunye nokusebenza kombala oluhlaza akuchaphazeleki.

•Ikhuselekile kwaye ayinavumba

Iyahambelana nemigangatho yehlabathi yokupakisha ukutya kunye nokunxibelelana kwamayeza.

Izicelo Ezininzi

Izithako zefilimu ezisebenzayo zeSILIKE's SILIMER Series ziyahambelana noluhlu olubanzi lweepolymers kunye neentlobo zeefilimu, kuquka:

•Iifilimu zeBOPP, CPP, PE, kunye nePP

•Iifilimu zokupakisha eziguquguqukayo, iingxowa zeplastiki, kunye namaphepha okukhusela

•Iimveliso zePolymer ezifuna iipropati eziphuculweyo zokutyibilika, ezichasene nokubetheka, kunye nomphezulu

Eziukungabikho kwemvulaizongezo zokutyibilika kunye nezokuthintela ukuvimbaqinisekisa ukusebenza kakuhle kwesitywino, ukuqhubekeka ngcono kokusetyenzwa, kunye nokuzinza komphezulu ixesha elide — isitshixo sokuvelisa iifilimu zokupakisha ezikumgangatho ophezulu nezithembekileyo.

Ngaba ujongene nemiba efana nokungangqinelani kwe-heat seal, ukufuduka kwe-slip agent, okanye i-white powder precipitation kwiifilimu ezidityanisiweyo?

I-SILIKE inceda abavelisi beepakeji ukuba baphelise le mingeni ngokusebenzisa ubuchule obusekelwe kwisayensi. Uthotho lwethu lwe-SILIMER lunceda abavelisi beepakeji ukuba baphelise le mingeni ngokusebenzisa izinto ezintsha eziqhutywa yisayensi.Isebenza kakuhleIzongezo zeSlip ezingafudukiyo kunye ne-Anti-Blockzibonelela ngokusebenza okuhlala ixesha elide, ukuvala ubushushu okuzinzileyo, kunye nomgangatho ophezulu womphezulu — ngaphandle kokuphazamisa ukucaca, ukuprintwa, okanye ukhuseleko lokutya.

Visit www.siliketech.com to explore SILIKE’s full range of functional plastic film additives and efficient non-migrating hot slip agents. You can also contact our technical team at amy.wang@silike.cn ukuze ufumane iingcebiso ezenzelwe wena malunga nezongezo zokupakisha eziguquguqukayo.

I-SILIKE — umenzi wakho wezongezo othembekileyo kwizisombululo ezintsha zokutyibilika kunye nezisombululo ezichasene nokuvalwa kwezixhobo zokupakisha eziguquguqukayo.

Ixesha leposi: Oktobha-19-2025