Sombulula Imingeni Ebalulekileyo Yokucubungula iPolymer - Ngaphandle kwePFAS!

Ukuphucula Ukusebenza, Imveliso, kunye Nokuzinza ngeSisombululo se-SILIKE's Free Fluorine

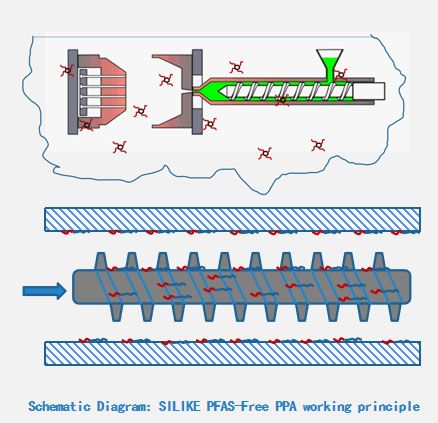

IiPPA zemveli ezifakwe i-fluorine, eziqulathe i-PFAS/PFOS, ngoku ziphantsi kwemiqathango yehlabathi. Ukuba ujongene nemingeni efana nokuqhekeka kwe-melt (sharkskin), ukwakheka kwe-die, okanye imveliso ephantsi kwimveliso ye-polymer, ngelixa uqhubeka nokuqinisa imithetho ye-PFAS kunye ne-fluorine efana ne-EU REACH kunye nemigangatho ye-US Environmental Protection Agency (EPA), umzekelo, i-EU Regulation PPWR (Packaging & Packaging Waste Regulation) iya kuthintela ukusetyenziswa kwe-PFAS ekupakisheni okungaphezulu kwemida echaziweyo ukususela phakathi kowama-2026. Uthotho lwe-SILIKE's SILIMER lubonelela ngesisombululo esingena-PFAS kunye ne-fluorine ukujongana nale mingeni.

Ezi zongezo zisebenza kakuhle zisusa imingeni eqhelekileyo yokucubungula ngaphandle kokuxhomekeka kwiikhemikhali ze-fluorochemicals, zithatha indawo yee-PPA ezifakwe i-fluorinated ngokupheleleyo. Zibonelela ngokusebenza kakuhle kokucubungula okulinganayo okanye okuphezulu xa kuthelekiswa nee-PPA zemveli ezisekelwe kwi-fluoro, ngelixa ziqinisekisa ukuthotyelwa kwemigangatho engqongqo yokusingqongileyo kunye nokhuseleko.

Uthotho lweSILIKE SILIMER luquka uluhlu lwezixhobo zokulungisa iipolymer ezingenayo iPFAS (iiPPA), ezifana nezongezo ezingenayo iPFAS eziyi-100%, iimasterbatches ezingenayo ifluorine, iiPPA ezingenayo ifluorine, kunye nezongezo ezingenayo iPTFE. Ezi zisombululo zinciphisa iingozi zePFAS kwaye zilungele ukuphucula ukusebenza kakuhle kwemveliso kwezi zicelo zilandelayo zoshishino:

● Iipolyolefins kunye neeresins zepolyolefin ezisetyenzisiweyo

● Iifilimu ezidumileyo, abadlali, kunye neefilimu ezininzi

● Ukufakelwa kwefayibha kunye ne-monofilament

● Ukukhupha ikhebula kunye nepayipi

● I-Masterbatch

● Ukudibanisa izinto

● Kwaye ngaphezulu...

Izixhobo zokuSebenza eziThandwayo zaBavelisi beePolymers zePFAS-Free

Ngokusekelwe kwingxelo yabathengi, izixhobo zokulungisa iipolymer ezidumileyo ze-SILIKE SILIMER Series PFAS kunye neemveliso ze-masterbatch ziquka.

Kutheni Ukhetha Izinto Zokuncedisa Ukucubungula IiPolymer Ezingenazo I-SILIKE's PFAS?

Njengezongezo zendabuko ezisekwe kwiFluoropolymer, izixhobo zethu zokucubungula ipolymer ezingenayo iPFAS zibonelela ngeenzuzo ezininzi eziphambili kwinkqubo yakho yemveliso:

Njengezongezo zendabuko ezisekwe kwiFluoropolymer, izixhobo zethu zokucubungula ipolymer ezingenayo iPFAS zibonelela ngeenzuzo ezininzi eziphambili kwinkqubo yakho yemveliso:

Ukuthamba Okuphuculweyo: Ukuthamba okuphuculweyo ngaphakathi nangaphandle ukuze kusetyenzwe kakuhle.

Ukuthamba Okuphuculweyo: Ukuthamba okuphuculweyo ngaphakathi nangaphandle ukuze kusetyenzwe kakuhle.

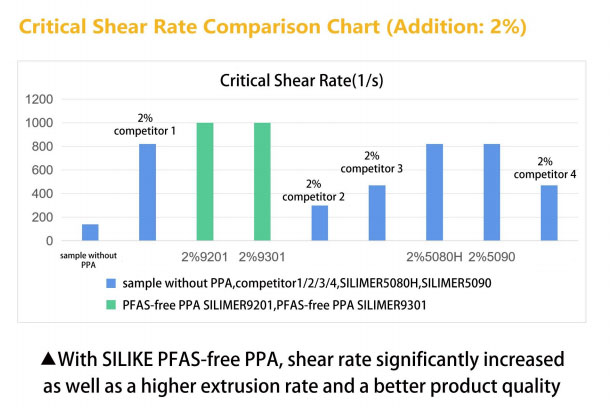

Isantya sokuKhupha esinyukileyo: Ukukhupha okuphezulu kunye nokwakheka okuncinci kokubola.

Isantya sokuKhupha esinyukileyo: Ukukhupha okuphezulu kunye nokwakheka okuncinci kokubola.

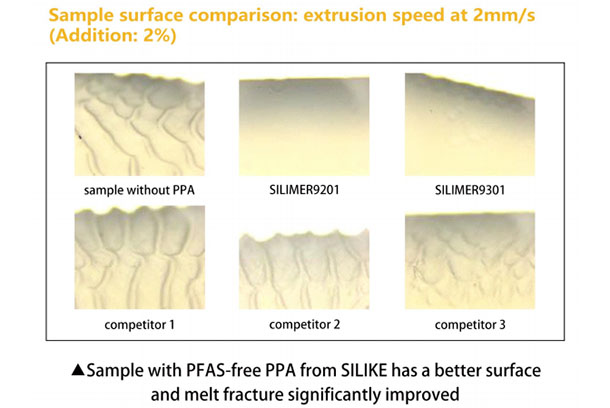

Susa ukuQhekeka okuNcibilikayo: Fumana umgangatho ongcono womphezulu kwaye unciphise iziphene.

Susa ukuQhekeka okuNcibilikayo: Fumana umgangatho ongcono womphezulu kwaye unciphise iziphene.

Ixesha Lokungasebenzi Elincitshisiweyo: Yandisa imijikelo yokucoca, nto leyo ekhokelela ekubeni ixesha lokungasebenzi komgca wemveliso libe lifutshane.

Ixesha Lokungasebenzi Elincitshisiweyo: Yandisa imijikelo yokucoca, nto leyo ekhokelela ekubeni ixesha lokungasebenzi komgca wemveliso libe lifutshane.

Ukhuseleko lweNdalo: Luhambelana nemigangatho yokhuseleko yehlabathi (i-REACH, i-EPA, njl.njl.) ngaphandle kokuphazamisa ukusebenza.

Ukhuseleko lweNdalo: Luhambelana nemigangatho yokhuseleko yehlabathi (i-REACH, i-EPA, njl.njl.) ngaphandle kokuphazamisa ukusebenza.

Izifundo zeTyala kunye nezicelo zeMveliso

Lahla izongezo ezindala zokucubungula: Ngaba ii-PPAs ze-SILIKE SILIMER Series PFAS-Free ziyindawo elungileyo yokutshintsha izongezo zokucubungula ezisekelwe kwi-Fluoropolymer?

Ukujongana nazo naziphi na iingxaki, nazi ezinye izinto ezibalulekileyo ekufuneka uzazi malunga nezisombululo zethu ezingena-fluorine.

Uthotho lwe-SILIKE SILIMER oluyi-100% olucocekileyo olungenazo ii-PFAS zokuncedisa ukucubungula ii-Polyolefins ekucutshungulweni kwePetrochemical

Iingenelo eziphambili:

• Ukunyibilika Komsinga: Ukuphucula ukucutshungulwa kwe-polyolefin resin, ngakumbi kwi-PE kunye ne-PP kwimveliso ye-masterbatch, kufezekisa ukuhamba okubushelelezi nokungaguquguqukiyo ngexesha lokukhupha kunye nokuxubana.

• Ukuthambisa: Ukuphucula ukuthambisa kwangaphakathi nangaphandle ukuze kube lula ukucutshungulwa kunye nobomi bexesha elide bezixhobo.

• Iimpawu zomphezulu: Phucula ukugqitywa komphezulu kwaye ususe iziphene ezifana nokuqhekeka okunyibilikileyo (isikhumba sooshaka).

Uthotho lwe-SILIKE SILIMER olusebenzisa i-PFAS-Free Polymer Processing Aids – I-Extrusion ethambileyo ye-Blown Film, i-Cast Film kunye nee-Multilayer Films

Iingenelo eziphambili:

• Ukuphelisa ukuqhekeka kwe-Melt.

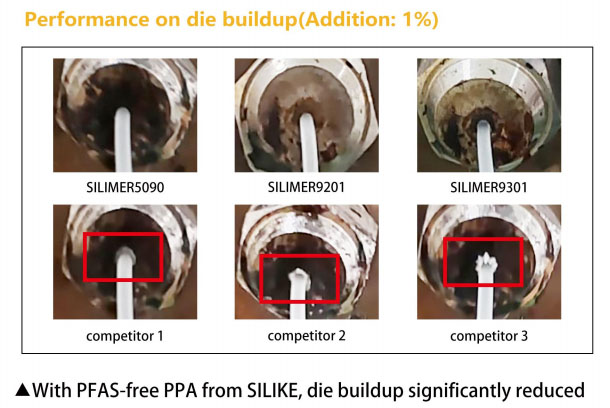

• Nciphisa Ukwakheka Kweentsimbi Ezininzi.

• Ukwanda kwemveliso: Fumana iziphumo eziphezulu ngaphandle kokuphazamiseka okuninzi.

• Uzinzo: Ukunciphisa inkunkuma yeplastiki kuxhasa iinjongo zokusingqongileyo.

• Akukho kuphazamiseka konyango lomphezulu: Akukho mpembelelo kwiinkqubo zokuprinta okanye zokugquma.

• Akukho Mphumo kwiSitywino: Igcina ukusebenza kokuvala okusemgangathweni ophezulu.

Izongezo zoLungiso lwePolymer zoKhupha iiCables kunye neePipe ngokuPhuculwa okuNgcono

Iingenelo eziphambili:

• Ukuncipha kokwakheka kwee-die.

• Uxinzelelo olusezantsi lomqolo.

• Amaqondo obushushu aphantsi okucubungula.

• Imveliso ephezulu.

• Inkangeleko Ephucukileyo Yomphezulu.

I-Fiber kunye ne-Monofilament Extrusion nge-SILIKE SILIMER Series PFAS-Free Solutions

Iingenelo eziphambili:

• Ukucoca i-Extrusion: Nciphisa ukwakheka kwe-die & screen pack, kunciphisa ixesha lokungasebenzi kunye nokugcinwa kwayo.

• Ukuhamba kwePolymer okuthambileyo: Ukuphucula ukunyibilika okulinganayo, okubangela ukuba iifayibha kunye ne-monofilaments zibe semgangathweni ophezulu kwaye zingaqhekeki kakhulu.

• Ukusebenza Kakuhle, Iindleko Eziphantsi: Ukwandisa imveliso ngokuthintela ukuxinana kweentsimbi kunye nokusilela kwentambo.

• Ihlala Ihleli Kwaye Ithobelana: Ifomula engenazo i-PFAS idlula izongezo zemveli ngelixa ihlangabezana nemigaqo engqongqo.

Izisombululo ze-PFAS-Free zeMibala kunye neeMasterbatches ezisebenzayo kunye nokuQokelela

Iingenelo eziphambili:

• Nciphisa Ukwakheka Kweentsimbi: Nciphisa ukugcinwa kunye nexesha lokungasebenzi ukuze inkqubo yemveliso ibe lula.

• Uxinzelelo oluphantsi: Yehlisa uxinzelelo lomqolo, iphucula ukusebenza kakuhle kokukhupha.

• Ukuthintela ukuxinana kwe-Filler kunye nePigment: Qinisekisa ukuba umbala kunye nomgangatho wezinto ezibonakalayo zihlala zifana.

• Utshintsho lweMbala oluKhawulezayo: Lungisa utshintsho lwemibala, nto leyo ephucula ukusebenza kakuhle kwemveliso.

• Ukonga Amandla: Nciphisa ukusetyenziswa kwamandla ngexesha lokucubungula.

• Umgangatho oPhuculweyo woMphezulu: Ukuphucula inkangeleko yemveliso yokugqibela, ukuhlangabezana nemigangatho yomgangatho ophezulu.

Izongezo zePolymer ezingenaFluorine kwiMibhobho (PE-RT, PEX kunye neHDPE) kunye neMibhobho

Iingenelo eziphambili:

• I-PFAS Ayisetyenziswa Kwimveliso Yeepayipi

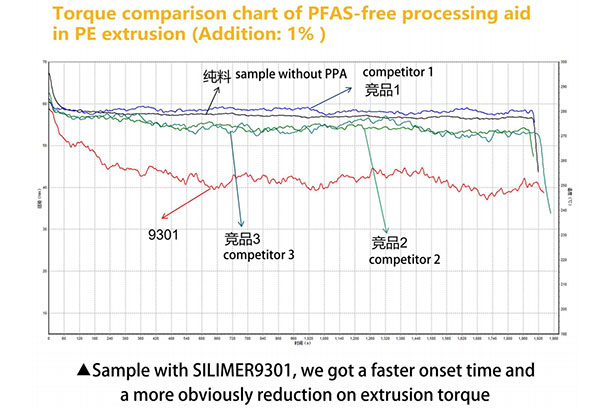

• I-Torque yokwehlisa i-Extruder

• Ukunciphisa Ukwakheka Kweentsimbi

• Ukungaguquguquki kwemveliso

• Ukuphucula i-Sliding Friction

• Ukukhupha okuthambileyo

• Nciphisa Ukusetyenziswa Kwamandla

Uvavanyo loVavanyo loKusebenza olufanelekileyo

Jonga indlela abanye abaThengi bethu abazibona ngayo iimveliso kunye neenkonzo zethu

★★★★★

"Ukutshintshela kwizixhobo zokulungisa ezingenayo i-PFAS ze-SILIKE kube lutshintsho olukhulu kuthi. Akuzange kusincede nje kuphela ukuba sithobele imithetho eqinileyo, kodwa kukwaphucule nokusebenza kakuhle kwemveliso yethu iyonke. Sibone ukuncipha okubonakalayo kokwakheka kwee-die kunye nokungayeki rhoqo kokugcinwa kwezinto, nto leyo ebangele ukuba imveliso iphume kakhulu kwaye kongiwe iindleko."

—Decio Malucelli, Polyolefin Manufacturer

★★★★★

"Iipolyolefin ezisebenza kakuhle, ezifana ne-LLDPE kunye ne-mLLDPE, zibonelela ngeempawu zefilimu ezibalaseleyo, nangona kunjalo, zinokuba nzima ukuzisebenzisa. Iingxaki eziqhelekileyo ziquka ukuqhekeka kwe-melt (i-sharkskin), ukwakheka kwe-die, ukwakheka kwejeli, ukungazinzi kwe-bubble, kunye neziphene zomphezulu. Ngezisombululo ze-SILIKE ezingenayo i-PFAS, sikwazile ukwenza lula iinkqubo zethu zemveliso. Ukuthambisa okuphuculweyo kunye nokususwa kwe-melt fractures kuphucule kakhulu umgangatho weefilimu zethu. Eyona nto ingcono? Asisakhathazeki ngempembelelo yokusingqongileyo yezithako ze-fluorinated."

— Sarah Mitchell, Inkampani yeFilimu Extrusion

★★★★★

"Isantya sethu sokukhupha izinto sinyukile, kwaye ixesha lokungasebenzi liye lehla kakhulu ukusukela oko satshintshela kwizixhobo zokulungisa ezingenayo i-SILIKE's PFAS. Sibona ukugqitywa komphezulu okungcono kwiintambo zethu kunye nemibhobho, kwaye imveliso isebenza kakuhle kunangaphambili."

— Michal Dlubek,Umvelisi weentambo kunye neepayipi

★★★★★

"Ukusebenzisa uthotho lwe-SILIKE's SILIMER kwi-fiber kunye ne-monofilament extrusion yethu kukhokelele ekuhambeni kakuhle kwe-polymer kunye nokusilela okuncinci kwe-strand. Siqaphele ukwehla kweendleko ngenxa yokuphazamiseka okuncinci kwemveliso kunye nokuhambelana okungcono kwemveliso."

— Emily Williams, Umvelisi wengca yokwenziwa

★★★★★

"Ngenxa yezongezo ezingenayo i-PFAS ezivela kwi-SILIKE, imveliso yethu ye-masterbatch ithambile, isebenza kakuhle, kwaye ikhawuleza. Siyakwazi ukutshintsha imibala ngokukhawuleza kwaye sifumane umgangatho ophezulu womphezulu ngelixa sinciphisa ukusetyenziswa kwamandla. Isisombululo esicetyiswayo kakhulu!"

—URodrigo de Paula Avelino,Umvelisi we-Color Masterbatch

★★★★★

"Njengenkampani ezinikele ekuzinzeni, savuya kakhulu kukufumana isisombululo esijongana neengxaki zokuveliswa kwemibhobho engena-PFAS kunye nokuphucula ukusebenza. Izisombululo zeplastiki ze-SILIKE ziphucule kakhulu iinkqubo zethu zokwenziwa kwemibhobho ye-HDPE kunye ne-PE-RT. Ukongezwa kwe-silicone masterbatch yazo okanye izongezo ze-SILIMER ze-PFAS ezingenayo inyuse ukuqina kwemveliso yethu, kwanciphisa ukungqubana ngaphakathi kwemibhobho, kwaye kwanciphisa i-torque ye-extruder, nto leyo ekhokelela kwimveliso ethambileyo kunye nokusebenza kakuhle okuphezulu."

—URicardo Bustamante, Umvelisi weMibhobho

Nxibelelana ne-SILIKE ukuze uqalise ukuphucula ukucutshungulwa kwePolymer yakho kunye nokuphucula ukusebenza kweenxalenye ezigqityiweyo.