I-SILIMER series non-precipitation slip kunye ne-masterbatch yokulwa nokuvimba yefilimu yokupakisha ukutya

Umgubo omhlophe ogqumayo kwingxowa yokupakisha ukutya kungenxa yokuba i-slip agent (i-oleic acid amide, i-erucic acid amide) esetyenziswa ngumvelisi wefilimu ngokwayo iyagquma, kwaye indlela esebenza ngayo i-amide slip agent yendabuko kukuba isithako esisebenzayo sifuduka siye kumphezulu wefilimu, senze umaleko omnye wokuthambisa wemolekyuli kwaye sinciphise i-friction coefficient yomphezulu wefilimu. Nangona kunjalo, ngenxa yobunzima obuncinci bemolekyuli ye-amide slip agent, kulula ukuyigquma okanye ukuyigquma, ngoko ke umgubo kulula ukuhlala kwi-composite roller ngexesha lenkqubo yokudibanisa ifilimu, kwaye umgubo kwi-raber roller uya kunamathela ngexesha lokucubungula ifilimu, okubangela ukuba umgubo omhlophe ocacileyo kwimveliso yokugqibela.

Ukuze kusonjululwe ingxaki yokuna kwe-amide slip agent yendabuko, i-SILIKE iphuhlise imveliso ye-co-polysiloxane eguquliweyo equlethe amaqela asebenzayo e-organic -I-masterbatch yefilimu engangenisi mvula ye-silimer seriesUmgaqo osebenzayo wale mveliso ngulo: Itsheyini ende yekhabhoni kunye ne-resin ziyahambelana ukudlala indima yokubambelela, kwaye itsheyini ye-silicone ifudukela kumphezulu wefilimu ukuze idlale indima yokutyibilika, ukuze idlale indima yokutyibilika ngaphandle kokuna ngokupheleleyo. Amanqaku acetyiswayo:SILIMER5064, I-SILIMER5064MB1, SILIMER5064MB2, SILIMER5065HB...

•Iingenelo eziqhelekileyo zemveliso

•Ukumelana okuhle nobushushu obuphezulu

•Ukusebenza okuhlala ixesha elide okugudileyo

•Ikhuselekile kwaye ayinavumba

•Ayichaphazeli ukuprintwa kwefilimu, ukuhlanganiswa, ukucaca

•Isetyenziswa kakhulu kwiifilimu zeBOPP/CPP/PE/PP......

•Idatha ethile yovavanyo lokusebenza efanelekileyo

Ukunciphisa ngempumelelo i-coefficient yokungqubana, akuchaphazeli inqanaba lenkungu kunye nokudluliselwa

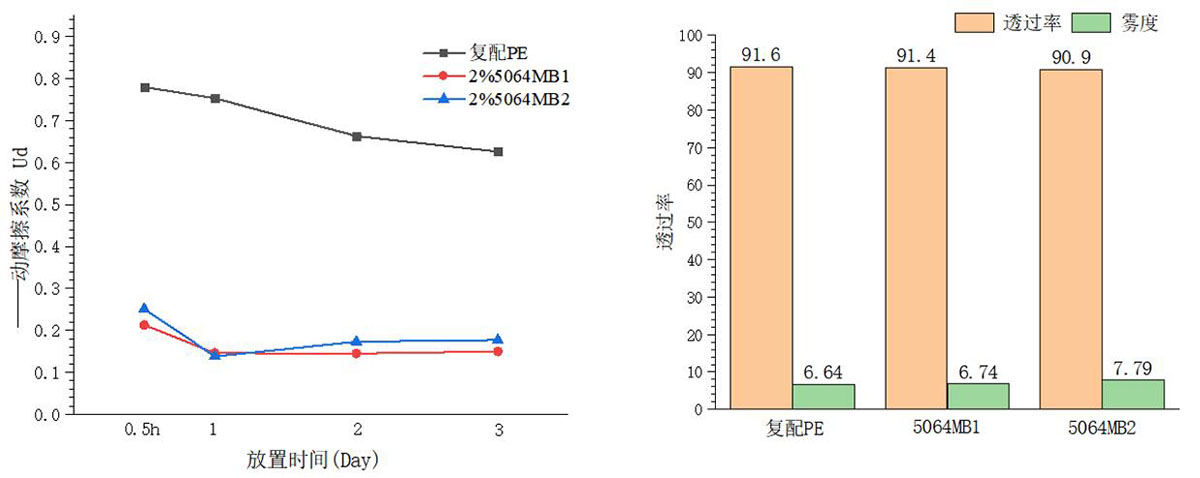

Ifomula yesiseko esilingisiweyo: 70%LLDPE, 20%LDPE, 10% metallocene PE

Njengoko kubonisiwe kuMfanekiso 1, i-coefficient yokungqubana kwefilimu emva kokongeza i-2% SILIMER 5064MB1 kunye ne-2% SILIMER 5064MB2 yehliswe kakhulu xa ithelekiswa ne-composite PE. Ngaphezu koko, njengoko kubonisiwe kuMfanekiso 2, ukongezwa kwe-SILIMER 5064MB1 kunye ne-SILIMER 5064MB2 ngokusisiseko akuzange kuyichaphazele inqanaba lenkungu kunye nokudluliselwa kwefilimu.

•I-coefficient yokungqubana izinzile

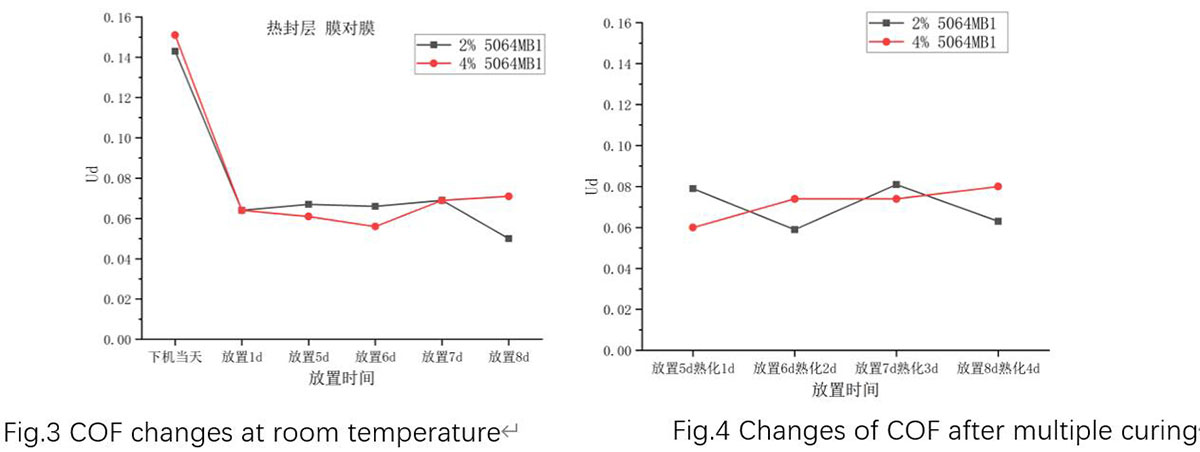

Iimeko zokuphilisa: ubushushu obuyi-45℃, ukufuma okungu-85%, ixesha leeyure ezili-12, amaxesha ama-4

Njengoko kubonisiwe kuMfanekiso 3 kunye noMfanekiso 4, kunokubonwa ukuba i-coefficient yokungqubana kwefilimu emva kokongeza i-2% SILIMER 5064MB1 kunye ne-4% SILIMER 5064MB1 ihlala kwixabiso elizinzileyo emva kokulungiswa kaninzi.

• Umphezulu wefilimu awugungqi kwaye awuchaphazeli umgangatho wezixhobo kunye nemveliso yokugqibela

Njengoko kubonisiwe kumfanekiso ongezantsi, sebenzisa ilaphu elimnyama ukusula umphezulu wefilimu nge-amide kunye nemveliso ye-SILIMER. Kuyabonakala ukuba xa kuthelekiswa nokusetyenziswa kwezongezo ze-amide,Uthotho lwe-SILIMERAyinawo umgubo obangela ukurhawuzelela kwaye ayinawo umgubo obangela ukurhawuzelela.

•Sombulula ingxaki yomgubo omhlophe kwi-composite roller kunye nebhegi yokugqibela yemveliso

Njengoko kubonisiwe kumfanekiso ongezantsi, emva kokuba i-composite roller idlule kwiimitha ezingama-6000 zefilimu ene-erucic acid amide, kukho ukuqokelelwa okucacileyo komgubo omhlophe, kwaye kukwakho nomgubo omhlophe ocacileyo kwibhegi yokugqibela yemveliso; Nangona kunjalo, isetyenziswa kunyeUthotho lwe-SILIMERSinokubona xa i-composite roller idlule kwiimitha ezingama-21000, kwaye ibhegi yokugqibela yemveliso yayicocekile kwaye intsha.

Ukongeza i-amide

Ukongeza uthotho lweSilimer

I-masterbatch yefilimu ye-SILIMER engenamvula, gcina ucango lokuqala lokhuseleko lokutya, qinisekisa ukhuseleko loxanduva lokupakisha ukutya! Ukuba uhlangabezana nayo nayiphi na imibuzo malunga neengxowa zokupakisha ukutya okanye ezinye iifilimu, nceda unxibelelane nathi, siya kukuvuyela ukwenza izisombululo zakho zibe zezakho!