Indlela yokuphucula ukurhawuzelelwa kweenyawo zezihlangu

Indlela yokuphucula ukurhawuzelelwa kweenyawo zezihlangu,

I-Masterbatch yokulwa nokukrala, I-masterbatch yokulwa nokukrala kweenyawo zezihlangu, Iarhente Yokulwa Nokunxiba, I-TPR, TR,

Inkcazo

I-Masterbatch elwa nokukrala (i-arhente yokulwa nokukrala) i-NM-6 yifomyula eyenziwe nge-pelletized ene-50% yesithako esisebenzayo esisasazwa kwi-Thermoplastic polyurethanes (TPU). Yenzelwe ngokukodwa iikhompawundi ze-TPU zezihlangu, inceda ekuphuculeni ukumelana nokukrala kwezinto zokugqibela kunye nokunciphisa ixabiso lokukrala kwi-thermoplastics.

Thelekisa nezongezo zeSilicone / Siloxane ezinobunzima obuphantsi beemolekyuli, ezifana neoyile yeSilicone, ulwelo lwesilicone okanye ezinye izongezo zokukrala, iSILIKE Anti-abrasion Masterbatch NM-6 kulindeleke ukuba inike ipropati engcono kakhulu yokumelana nokukrala ngaphandle kwempembelelo kubulukhuni kunye nombala.

Iiparameters ezisisiseko

| Ibanga | I-NM-6 |

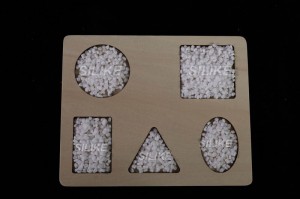

| Inkangeleko | Ipellet emhlophe |

| umxholo wezithako ezisebenzayo % | 50 |

| I-resin yokuthwala | I-TPU |

| Isalathisi sokunyibilika (190℃, 2.16KG) | 25.0 (ixabiso eliqhelekileyo) |

| Idosi % (w/w) | 0.5~5% |

Iinzuzo

(1) Ukumelana nokukrala okuphuculweyo kunye nexabiso lokukrala eliphantsi

(2) Nika ukusebenza kokucubungula kunye nokubonakala kwezinto zokugqibela

(3) Ilungele ukusingqongileyo

(4) Akukho mpembelelo kubulukhuni kunye nombala

(5) Isebenza kakuhle kwiimvavanyo ze-DIN, ASTM, NBS, AKRON, SATRA, GB abrasion

Izicelo

(1) Izihlangu zeTPU

(2) Ezinye iiplastiki ezihambelana neTPU

Kusetyenziswa kwanjani

I-SILIKE Anti-abrasion masterbatch ingacutshungulwa ngendlela efanayo ne-resin carrier abasekelwe kuyo. Ingasetyenziswa kwinkqubo yokuxuba i-melt yakudala efana ne-Single / Twin screw extruder, i-injection molding. Kucetyiswa umxube ophathekayo kunye nee-virgin polymer pellets.

Cebisa idosi

Xa kongezwa kwi-TPU okanye kwi-thermoplastic efanayo kwi-0.2 ukuya kwi-1%, kulindeleke ukuba ukucubungula kunye nokuhamba kwe-resin kuphuculwe, kubandakanya ukuzaliswa okungcono kwe-mold, i-extruder torque encinci, ii-lubricants zangaphakathi, ukukhululwa kwe-mold kunye ne-output ekhawulezayo; Kwinqanaba eliphezulu lokongeza, i-1 ~ 2%, kulindeleke iipropati zomphezulu eziphuculweyo, kubandakanya ukuthambisa, ukutyibilika, i-coefficient ephantsi yokungqubana kunye nokumelana okukhulu kwe-mar/scratch kunye nokukrala.

Iphakheji

25Kg/ibhegi, ibhegi yephepha lobugcisa

Indawo yokugcina izinto

Thutha njengekhemikhali engenabungozi. Gcina kwindawo epholileyo, enomoya owaneleyo.

Beka ubomi kwishelufa

Iimpawu zokuqala zihlala zingaguquki kangangeenyanga ezingama-24 ukusukela kumhla wokuveliswa, ukuba zigcinwe kwindawo yokugcina ecetyiswayo.

I-Chengdu Silike Technology Co., Ltd ngumvelisi kunye nomthengisi wezinto ze-silicone, ozinikele kwi-R&D yokudityaniswa kwe-Silicone kunye ne-thermoplastics kangangeminyaka engama-20.+ years, products including but not limited to Silicone masterbatch , Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cnThere are a variety of anti-abrasion masterbatches available for shoe sole applications. These masterbatches are typically made from a combination of polymers, fillers, and additives that provide increased abrasion resistance and durability. Common polymers used in these masterbatches include SBS, EVA, TR, TPR, rubber, and polyurethane. Fillers such as carbon black, silica, and talc are also used to improve abrasion resistance.

Izongezo zeSilicon zasimahla kunye neesampuli zeSi-TPV ezingaphezulu kwamaBanga ali-100

Uhlobo lwesampulu

$0

- Ngaphezulu kweminyaka engama-50

amabakala eSilicone Masterbatch

- 10+

amabakala eSilicone Powder

- 10+

amabakala I-Masterbatch yokulwa nokukrwela

- 10+

amabakala I-Masterbatch yokulwa nokukrala

- 10+

amabakala e-Si-TPV

- 8+

amabakala e-Silicone Wax

-

Ifowuni

-

I-imeyile

-

I-Whatsapp

I-Whatsapp

-

Phezulu

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur